Are you struggling to find reliable vinyl flooring suppliers? It’s tough. Making the wrong choice can cost you dearly.

The key is to look beyond just the price tag. Focus on communication, transparency, and verified experience to avoid common pitfalls with vinyl flooring suppliers.

Choosing a new vinyl flooring supplier can feel like navigating a minefield. You’re looking for top-quality LVT or SPC flooring, consistent supply, and a partner you can trust. But how do you sidestep the potential problems? I’ve seen many buyers make mistakes that could have been avoided. As a factory owner in China, exporting to North America, the UK, and the Middle East, I want to share some common issues and how you, as a B2B buyer, can steer clear of them. Let’s make sure your next flooring order is a success, not a headache.

Why is relying solely on low price often a red flag when selecting a vinyl flooring supplier?

Tempted by an incredibly low price for vinyl flooring? It’s a common lure. But this can quickly turn into a costly mistake.

A rock-bottom price often signals compromises in quality, materials, or service, leading to bigger problems and expenses for B2B buyers down the line.

The Hidden Costs of "Too Good to Be True" Pricing

When I talk to buyers, like Aiden from the UK or Lori from the US, price is always a major factor. And I get it – everyone wants a good deal, especially for wholesale LVT and SPC flooring. But an unusually low price from a vinyl flooring supplier should make you pause and ask, "What’s the catch?"

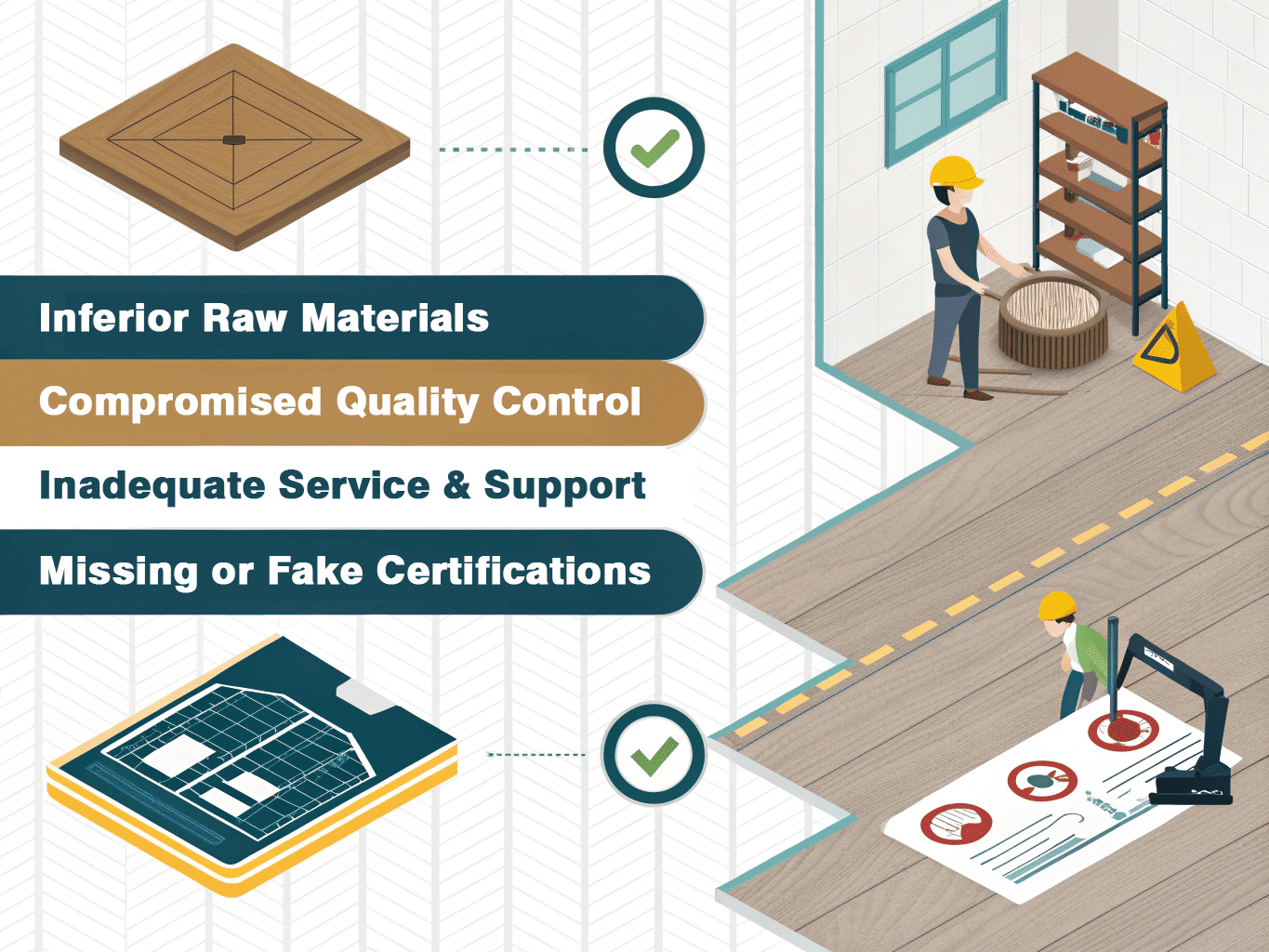

Often, that super low price means corners are being cut somewhere. Here’s what I’ve seen happen:

- Inferior Raw Materials: To offer a lower price, some suppliers might use substandard raw materials. This can mean your LVT or SPC flooring won’t perform as expected. It might wear out faster, dent easily, or even have issues with dimensional stability. For example, a cheaper wear layer might not be as durable, leading to premature signs of use.

- Compromised Quality Control: Robust quality control costs money. A supplier offering an extremely low price might be skimping on QC checks. This can lead to inconsistent batches, color variations, or even defects in the locking systems of click LVT or SPC. I remember a buyer telling me about receiving a shipment where the click mechanism was faulty on nearly 20% of the planks – a disaster for their project timeline and budget.

- Inadequate Service & Support: Good customer service, reliable communication, and after-sales support are part of the package. If the price is too low, these are often the first things to suffer. You might find it hard to get updates, or worse, encounter radio silence if there’s a problem.

- Missing or Fake Certifications: Reputable suppliers invest in getting their products certified for quality, safety, and environmental standards. These certifications cost money. A supplier offering a suspiciously low price might not have these, or worse, might provide fake documents. This was a huge pain point for Aiden; he once faced issues because a previous supplier falsified certificates. Always verify!

Ultimately, a price that seems too good to be true often is. The initial savings can be quickly wiped out by the costs of dealing with poor quality products, project delays, or unhappy customers. It’s about finding the right balance between a competitive price and the value that comes with quality, reliability, and genuine partnership.

How can buyers avoid suppliers with poor communication or lack of transparency about production?

Frustrated by suppliers who go silent or are vague about production? This is a serious issue. It breeds uncertainty and can hide bigger problems.

Buyers can avoid suppliers with poor communication by establishing clear expectations, scheduling regular updates, and insisting on factory transparency from the outset.

Building Trust Through Openness and Clear Channels

In my experience as a B2B supplier of LVT and SPC flooring, communication is everything. When a buyer like Lori, who is a COO and needs to ensure smooth operations, faces a supplier who doesn’t communicate well, it’s a recipe for disaster. Delayed shipments or quality issues, often stemming from poor communication1, were among her biggest frustrations.

So, how do you proactively avoid these communication black holes and ensure transparency?

- Set Clear Communication Protocols Early:

- Who is your main point of contact? Get their direct line and email.

- What is the expected response time for queries? Agree on this.

- How often will you receive production updates? Weekly updates with photos or videos can be very reassuring.

I always make sure my clients at CloudsFlooring know exactly who to contact and when they can expect to hear from us.

- Ask for Production Transparency:

- Can you visit the factory? A supplier confident in their processes will welcome a visit. We have two factories covering about 20,000 square meters, and we’re always open to buyer inspections.

- Will they share their production schedule for your order? This helps you plan.

- Can they provide batch testing results or internal QC reports? This shows they are serious about quality.

- Look for Red Flags in Initial Interactions:

- Are they slow to respond to your initial inquiries?

- Are their answers vague or evasive?

- Do they seem unwilling to provide detailed information about their processes or materials?

These early warning signs can indicate future communication problems. I once had a prospective client mention that another supplier took days to answer simple questions – this is a major red flag.

Here’s a simple table to outline key communication strategies:

| Strategy | Action | Benefit |

|---|---|---|

| Define Contact Points | Identify a dedicated sales rep and their backup. | Ensures consistent and timely responses. |

| Schedule Updates | Agree on regular (e.g., weekly) progress reports. | Keeps you informed and reduces anxiety. |

| Request Factory Tour | Ask for a virtual or in-person factory visit. | Verifies production capabilities and openness. |

| Document Everything | Keep records of all communications, agreements, and specifications. | Prevents misunderstandings and disputes. |

| Clarify QC Process | Understand their quality control checkpoints and documentation. | Builds confidence in product quality. |

Transparent suppliers understand that B2B purchasing is about building a partnership. They won’t shy away from showing you how they work. Good communication and transparency are not just nice-to-haves; they are essential for a smooth, reliable supply chain, especially when dealing with international orders for LVT and SPC flooring.

What checks can verify if a supplier has genuine export experience and capabilities?

Concerned if a new supplier can actually handle international shipping and customs? It’s vital. Export inexperience can derail your entire order.

Verify a supplier’s export experience by checking their export licenses, asking about past shipments to your region, and inquiring about their logistics partnerships.

Ensuring Your Goods Arrive Smoothly

Exporting isn’t just about making great LVT or SPC flooring; it’s a complex process involving documentation, logistics, customs regulations, and international payment methods. As a factory that regularly exports to North America, the UK, and the Middle East, I know how crucial it is to get this right. For B2B buyers, especially those sourcing from overseas like Aiden and Lori do from China, a supplier’s export capability is as important as their product quality. A slip-up here can mean costly delays, goods stuck at port, or unexpected fees.

So, what practical steps can you take to verify a potential supplier’s export credentials?

- Request Export Documentation:

- Business License: Ensure it includes export rights.

- Export License/Registration: In China, this is crucial. Ask for a copy.

- Certifications for Your Market: Do they have CE (for Europe), FloorScore (for North America), or other relevant certifications for products intended for your country? This shows they understand and meet international standards. I make sure CloudsFlooring has the necessary certifications for our main export markets.

- Inquire About Their Export History:

- Which countries do they mainly export to? Experience in your specific region (e.g., North America, UK) is a big plus because they’ll be familiar with your ports and customs procedures.

- Can they provide (anonymized) Bills of Lading or references from freight forwarders they work with? This is direct proof of export activity.

- Ask about their experience with Incoterms. Their understanding of terms like FOB, CIF, DDP will indicate their familiarity with international trade practices.

- Evaluate Their Logistics and Shipping Knowledge:

- Who are their partner freight forwarders? Established relationships with reliable forwarders are a good sign.

- How do they handle packaging for export? Proper packaging is vital to prevent damage during transit. We ensure our LVT and SPC flooring is securely packed for long sea voyages.

- What’s their process for customs clearance documentation? They should be able to clearly explain how they prepare and manage this.

Here’s a checklist you can use:

| Verification Check | What to Ask/Look For | Why It’s Important |

|---|---|---|

| Export Licenses1 | Copy of business license with export rights, specific export license. | Confirms legal ability to export. |

| Target Market Experience | List of countries exported to; experience with your specific country/port. | Familiarity with your region’s customs, shipping lines, and requirements. |

| Shipping & Logistics Partners | Names of freight forwarders, shipping lines used. | Indicates established logistics network. |

| Knowledge of Incoterms2 | Discuss common Incoterms (FOB, CIF, etc.). | Shows understanding of international trade responsibilities and costs. |

| Product Certifications for Export | CE, FloorScore, ISO, etc., relevant to your market. | Ensures product meets your country’s standards and facilitates customs clearance. |

| Handling of Export Documentation | Process for preparing commercial invoice, packing list, certificate of origin, B/L. | Efficiency here prevents delays and customs issues. |

A supplier who is hesitant or unable to provide clear answers and documentation for these points might lack genuine export experience. This could expose you to significant risks, such as those Aiden and Lori worried about – shipment delays leading to missed selling seasons, or even goods being held up by customs. Taking the time to verify these capabilities is a crucial step in selecting a reliable international vinyl flooring supplier.

Conclusion

Avoiding pitfalls means looking beyond price. Prioritize clear communication, production transparency, and verified export experience to secure a reliable vinyl flooring supplier for your B2B needs.

The above data is for reference only.