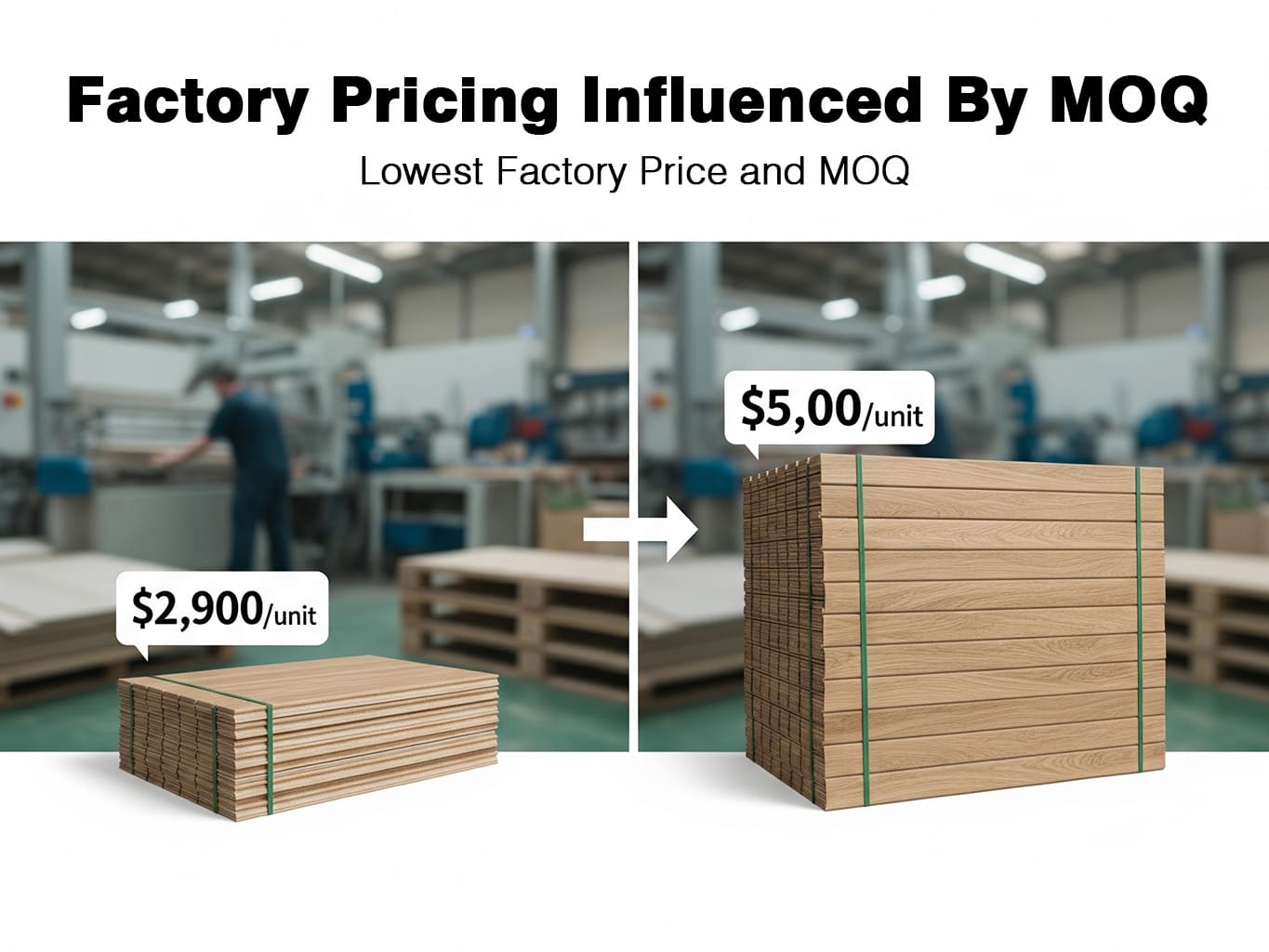

Struggling to get the best price from flooring manufacturers? Minimum Order Quantities (MOQs) play a huge role in what factories quote. Understanding this link is vital for importers.

Minimum Order Quantities significantly influence factory pricing because higher volumes allow manufacturers to achieve economies of scale, spreading fixed production costs across more units, which results in a lower per-unit factory price for importers.

As a manufacturer of LVT and SPC flooring here in China, I often talk with large company buyers. These include clients like Aiden from the UK or Lori from the US. They are confident and focused on getting competitive prices while ensuring top quality.

One of the first things that comes up in these discussions is often about MOQs. It is crucial to understand that MOQs are not just random numbers. They directly affect the price we can offer. Let me explain how MOQs are connected to the factory price you get.

Do manufacturers typically offer their lowest Factory Price only to buyers meeting substantial MOQ thresholds?

Are you aiming for the absolute best price on your flooring orders? Many buyers wonder if hitting a large MOQ is truly the only way to unlock those lowest factory prices1.

Yes, manufacturers typically reserve their lowest factory prices for buyers who meet substantial MOQ thresholds because larger orders enable them to optimize production, reduce per-unit fixed costs, and secure better pricing on raw materials due to economies of scale.

From my experience running LVT and SPC production lines, manufacturers always aim for efficiency. This efficiency is directly tied to the quantity of products we produce. When we produce larger quantities, it means our machinery runs for longer periods without frequent changeovers.

Setting up a production line, whether for LVT or SPC, involves fixed costs. These include labor, electricity, and machine depreciation. These costs exist regardless of whether we run for 500 square meters or 5,000.

For example, producing a small batch of flooring requires the same initial setup time and effort as a much larger batch. This includes preparing the raw materials, calibrating the machines, and managing the initial labor. When these fixed costs are spread over a greater number of units in a large order, the cost per unit decreases significantly. It becomes much more profitable for us.

Furthermore, we as manufacturers also have our own suppliers for raw materials. These include PVC resin, stone powder, and stabilizers for SPC flooring, or vinyl and fiberglass for LVT. These suppliers also have their own MOQs2. By placing larger orders for finished flooring, we can, in turn, place larger orders for our raw materials. This allows us to get better bulk pricing from our material suppliers.

This cost saving is then reflected in the lower per-unit price we can offer to our buyers for larger MOQs. A large order ensures we maximize production efficiency, minimize downtime, and benefit from bulk purchasing of materials, all of which contribute to the lowest possible factory price.

| Factor | Lower MOQ Impact | Higher MOQ Impact |

|---|---|---|

| Fixed Costs per Unit | Higher (spread over fewer units) | Lower (spread over more units) |

| Raw Material Cost | Potentially higher (smaller material orders) | Lower (bulk material purchasing) |

| Production Efficiency | Lower (more frequent setups, downtime) | Higher (continuous, optimized runs) |

| Manufacturer Profit Margin | Lower (less efficient, higher costs) | Higher (more efficient, lower costs) |

| Per-Unit Factory Price | Higher for the buyer | Lower for the buyer |

Can importers ordering below the standard MOQ expect to pay a higher per-unit Factory Price?

Worried about placing an order too small to hit the standard MOQ? It is a common concern for importers. Find out if lower quantities always mean a higher price.

Yes, importers ordering below the standard MOQ should expect to pay a higher per-unit factory price3 because manufacturers must cover their fixed production costs and still make a profit even with smaller, less efficient production runs, leading to a higher cost allocation per item.

When a buyer like Aiden or Lori wants to place an order that falls below our standard MOQ, it presents a different set of challenges for us as a factory. Our goal is always to deliver top-quality LVT and SPC flooring, but the economics change with smaller volumes.

Even for a smaller order, we still incur significant fixed costs. This includes the cost of setting up the production lines, the labor for calibration, and the initial raw material preparation. These costs do not disappear just because the order quantity is smaller. If we produce fewer units, these fixed costs are distributed among a much smaller number of items. This naturally drives up the per-unit cost.

For example, if it costs $500 to set up a specific LVT design on a line, and a standard MOQ is 1000 square meters, the setup cost per square meter is $0.50. If an order is only 500 square meters, the setup cost per square meter effectively doubles to $1.00, just for that fixed cost. This increase must be reflected in the unit price to ensure we do not lose money.

Also, for smaller orders, we might not be able to buy raw materials in the most cost-effective bulk quantities from our own suppliers. This means our material cost per unit could be higher, further impacting the final price. Sometimes, to accommodate a lower MOQ, we might need to adjust our production schedule, which can lead to inefficiencies or even disrupt larger, more profitable orders. This operational flexibility often comes at a premium.

As a B2B wholesaler, our business model relies on efficient, large-scale production. While we strive to be flexible and meet client needs, a lower MOQ means that the fixed costs per unit increase. To maintain our profit margins and cover operational expenses, we have to adjust the per-unit price upwards. This is a common practice across the manufacturing industry. It ensures the supplier remains financially viable while still delivering the product.

| Installation Aspect | Scenario: Below Standard MOQ | Scenario: Standard MOQ Met |

|---|---|---|

| Production Run Efficiency | Less efficient, more setup cost per unit. | Highly efficient, lower setup cost per unit. |

| Raw Material Procurement | Less bulk discount, higher material cost per unit. | More bulk discount, lower material cost per unit. |

| Labor Cost per Unit | Higher (fixed labor for shorter run) | Lower (fixed labor spread over more units) |

| Overhead Allocation | Disproportionately higher per unit. | Efficiently spread per unit. |

| Resulting Per-Unit Price | Higher for the buyer. | Lower for the buyer. |

Is negotiating MOQs sometimes possible, especially when building a new relationship or for custom orders?

Feeling stuck with high MOQs when you are just starting or need something unique? Many new buyers wonder if there is any room to negotiate.

Negotiating MOQs is often possible, especially when initiating a new relationship, for custom orders, or if a buyer can demonstrate long-term potential, by offering to pay a slightly higher unit price, combining orders, or accepting available stock.

I remember when I first started in the flooring business. It was a constant learning curve, especially when it came to supplier relationships and MOQs. While I now run a factory, I used to be on the buyer side, trying to make my initial orders work. The MOQ seemed like a big barrier then, but I quickly learned that negotiation is a fundamental part of doing business, especially in China.

For new buyers like Aiden or Lori, who are looking to establish a long-term partnership1, we are often willing to be flexible. We understand that a first order might be smaller, perhaps to "test the market" or verify quality. My experience has shown that building trust and a solid relationship matters a lot. If a buyer is transparent about their business plan, sales projections, and commitment to future, larger orders, it can open doors. We evaluate potential for ongoing business.

For example, a buyer might ask for a smaller initial quantity of a specific LVT or SPC style. In such cases, we might agree to a lower MOQ but at a slightly higher per-unit price to cover the increased fixed costs. This way, the buyer gets their initial order, and we cover our expenses while hoping for a long-term, profitable relationship. We have found this approach to be mutually beneficial.

Another strategy is to combine different products to meet a factory’s overall production threshold. For instance, if a buyer wants a custom color LVT but cannot meet the MOQ for that one item, they might combine it with an order for a standard SPC product. This helps us meet our production goals across multiple lines.

Also, if a buyer is flexible with slight variations or is willing to take current "off-the-shelf" stock, we can sometimes accommodate smaller quantities. However, we are a B2B wholesale factory mainly focused on made-to-order for export markets like North America, UK, and the Middle East. Therefore, off-the-shelf options are limited.

It is crucial for buyers to remember that manufacturers also need to make a profit. Pushing too hard for an impossibly low MOQ without considering our costs can damage the relationship.

| Negotiation Strategy | How it Works | Potential Outcome |

|---|---|---|

| Be Honest & Transparent | Share your business plan and long-term potential. | Builds trust, opens flexibility for future orders. |

| Offer Higher Unit Price | Agree to pay a slightly higher price for a lower MOQ. | Covers fixed costs for smaller runs, gains initial order. |

| Combine Orders | Mix different products or styles to meet total MOQ. | Manufacturer meets overall production goal, buyer gets variety. |

| Accept Standard Stock/Less Customization | Choose existing designs or limit unique features. | Reduces production complexity, lowers MOQ. |

| Inquire About Off-Season Production | Ask if lower MOQs are possible during slower periods. | Manufacturers might be more flexible when order books are not full. |

| Long-Term Commitment | Demonstrate clear plans for consistent, larger future orders. | Encourages manufacturers to invest in the relationship. |

Conclusion

MOQs are essential for manufacturers to cover costs and ensure profitability. Importers should aim for higher quantities for better pricing, but negotiation is possible for smaller orders, especially by building trust and understanding production realities.

The above data is for reference only.

-

Discover insights on building lasting relationships with suppliers, which can lead to better terms and flexibility in orders. ↩ ↩

-

Exploring this topic will provide insights into how minimum order quantities affect costs and pricing strategies in the industry. ↩

-

This resource will clarify the economic principles behind pricing strategies, helping buyers make informed decisions about order sizes. ↩