Worried about your vinyl flooring’s durability? Do you question what makes it last? Poor quality flooring can cost you.

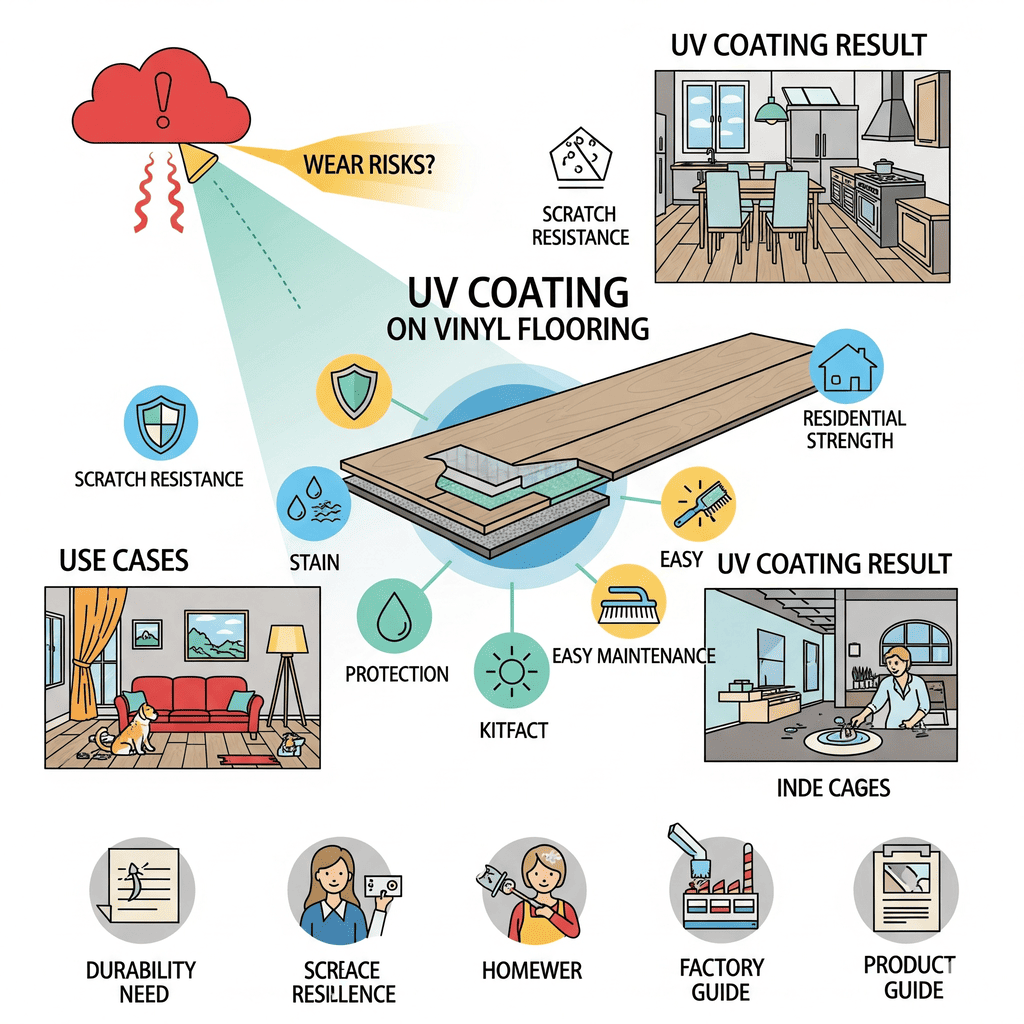

UV coating is a critical layer on vinyl flooring. It protects the floor from scratches, stains, and fading. This coating also makes the floor easy to clean. It enhances the overall durability and lifespan of the product.

I often hear buyers ask about what makes our vinyl flooring so tough. From my experience, a key part of the answer lies in the UV coating. This layer is more important than many people realize.

What benefits does UV coating offer?

Do you know what makes vinyl flooring last longer? Are you missing out on protecting your investment? Many buyers overlook the power of the right coating.

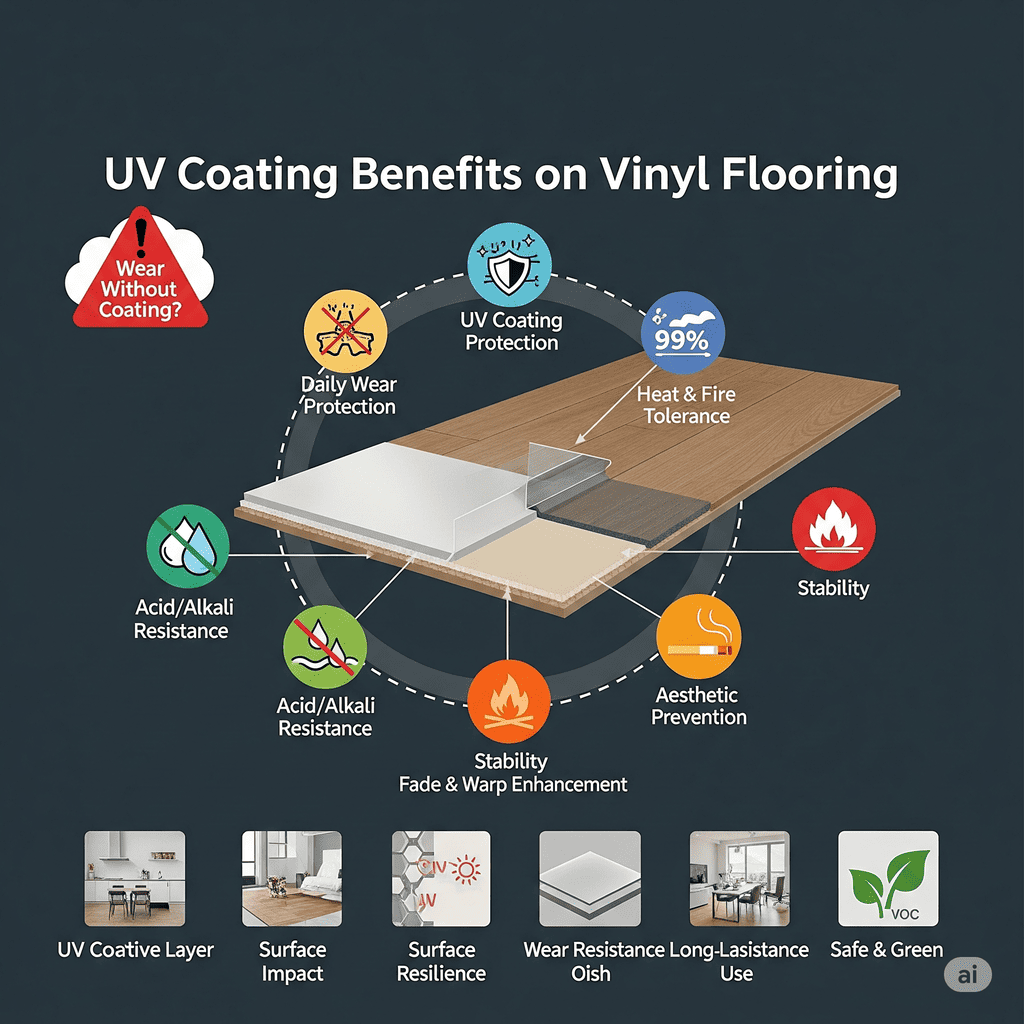

UV coating on vinyl flooring gives many benefits. It protects against daily wear and tear. It also stops color fading from sunlight. This layer improves stain resistance and makes cleaning simple. It adds to the overall toughness of the floor.

Key Advantages of UV Coating

UV coating1 is like a strong shield for your vinyl flooring. It protects the floor from many common problems. This helps the floor look good for a long time. For example, sunlight can make colors fade. UV coating stops this from happening. It means your floor keeps its original look for years. We see this with our floors; they keep their vibrant colors.

Comprehensive Protection and Performance

The benefits of UV coating go deep. It provides wear resistance2 up to 99%. This means floors last longer even in busy areas like offices or stores. It also resists chemicals such as acids and alkalis. This is very important for kitchens or labs where spills happen.

Our coatings include alumina crystals. These make the floor resistant to chemicals and high temperatures. You can even put out a cigarette on it without damage. UV coating also stabilizes the floor. It stops fading or warping from sunlight. This is because the curing process creates a strong structure.

Plus, our UV coatings are eco-friendly. They do not have harmful volatile organic compounds (VOCs). This makes them a safe choice for any space. The coating can be clear or frosted. This helps show off the floor’s design.

| Benefit | Description |

|---|---|

| Wear Resistance | Protects against daily wear, up to 99% resistance, long lifespan. |

| Chemical Resistance | Resists acids, alkalis, and other chemicals due to alumina crystals. |

| Fire/Heat Resistance | Withstands high temperatures; prevents damage from heat sources like cigarettes. |

| Stability | Prevents fading and warping from sunlight exposure. |

| Optical Clarity | Enhances floor aesthetics; available in clear or frosted finishes. |

| Eco-Friendliness | Free of volatile organic compounds (VOCs), better for indoor air. |

Do more UV layers mean better performance?

Are you thinking more layers always mean better quality? Is this true for UV coating? Many buyers assume this.

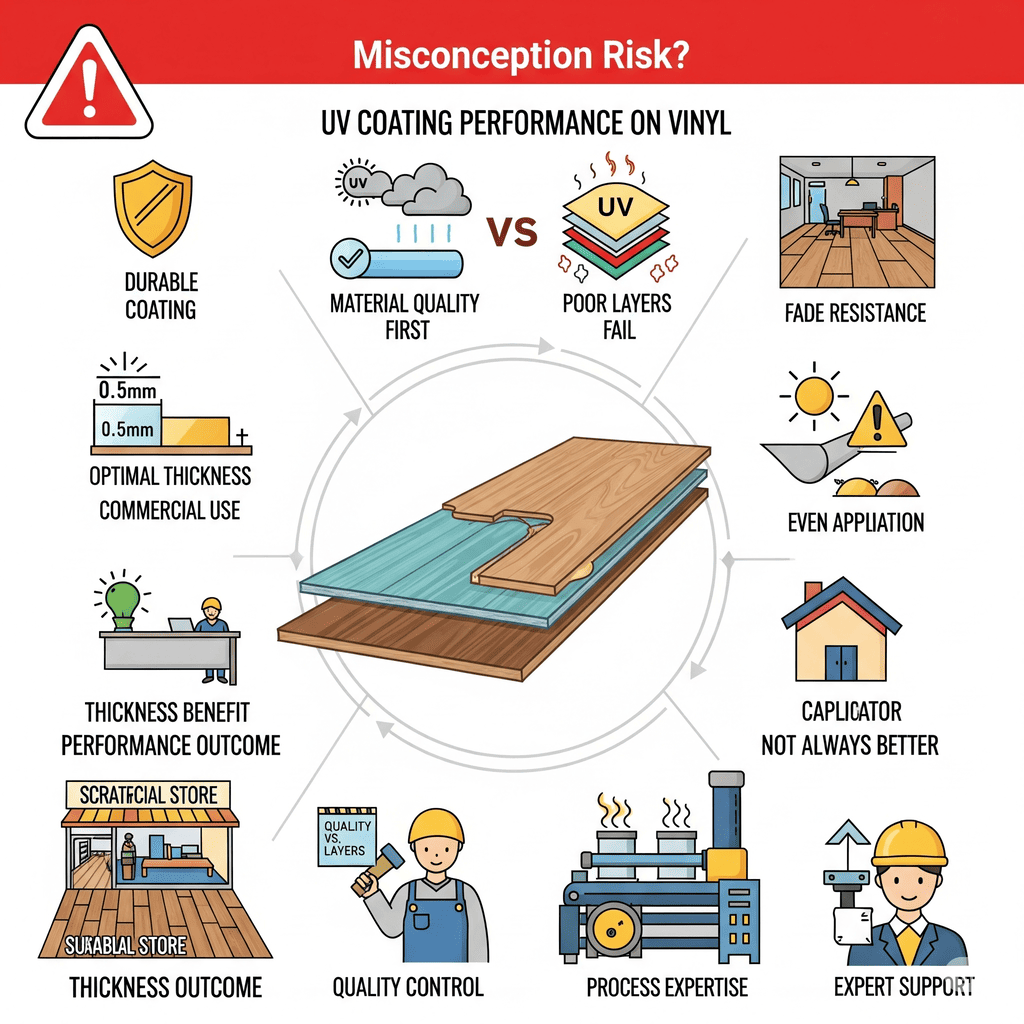

More UV layers on vinyl flooring do not always mean better performance. Quality of the coating material and proper curing are more important than just the number of layers. A few high-quality, well-cured layers often perform better than many poor-quality layers.

The Importance of Quality Over Quantity

It is easy to think that more is always better. But this is not always true for UV coating. I have seen many floors with many layers of coating that still fail quickly. The material quality of each layer matters most. If the raw materials for the UV coating are not good, adding more layers will not help. It can even make the floor look cloudy or peel. We focus on the best raw materials first.

Impact of Multiple Layers and Thickness

Adding more UV layers, or using thicker coatings, can improve performance. For example, some manufacturers offer "Super UV" double layers. We find this can increase resistance to scratches, wear, and stains.

Thicker wear layers are also very important. A 0.5mm wear layer handles heavy traffic much better than a 0.33mm one. This shows how thickness adds to durability. For high-traffic commercial spaces, we always recommend thicker wear layers. We know that a good, thick layer, like 0.5mm, is essential for our commercial clients.

But even with more layers or thickness, the quality of the coating material itself is critical. A single high-quality layer, if properly made, can still offer great protection.

Curing Process is Key

The curing process1 is also very important. UV coating uses a special light to harden. If the curing is not done right, the coating will not be strong. It might remain soft or become brittle. This means it will not protect the floor well. It can scratch easily. It can also wear away fast. A factory must have good machines and a skilled team for proper curing. We invest a lot in this part of our process.

| Factor | Less Important | More Important |

|---|---|---|

| Number of Layers | Only counting layers | Quality of each layer |

| Curing Process | Rushing curing | Proper and full curing |

| Raw Material | Cheap, low-grade material | High-grade, durable material |

| Application Skill | Unskilled application | Precise, even application |

| Wear Layer Thickness | Thin layers for heavy use | Optimal thickness (e.g., 0.5mm for commercial) |

How is UV coating quality ensured?

Are you worried about getting low-quality products? Do you know how to check UV coating quality? Many buyers struggle with this.

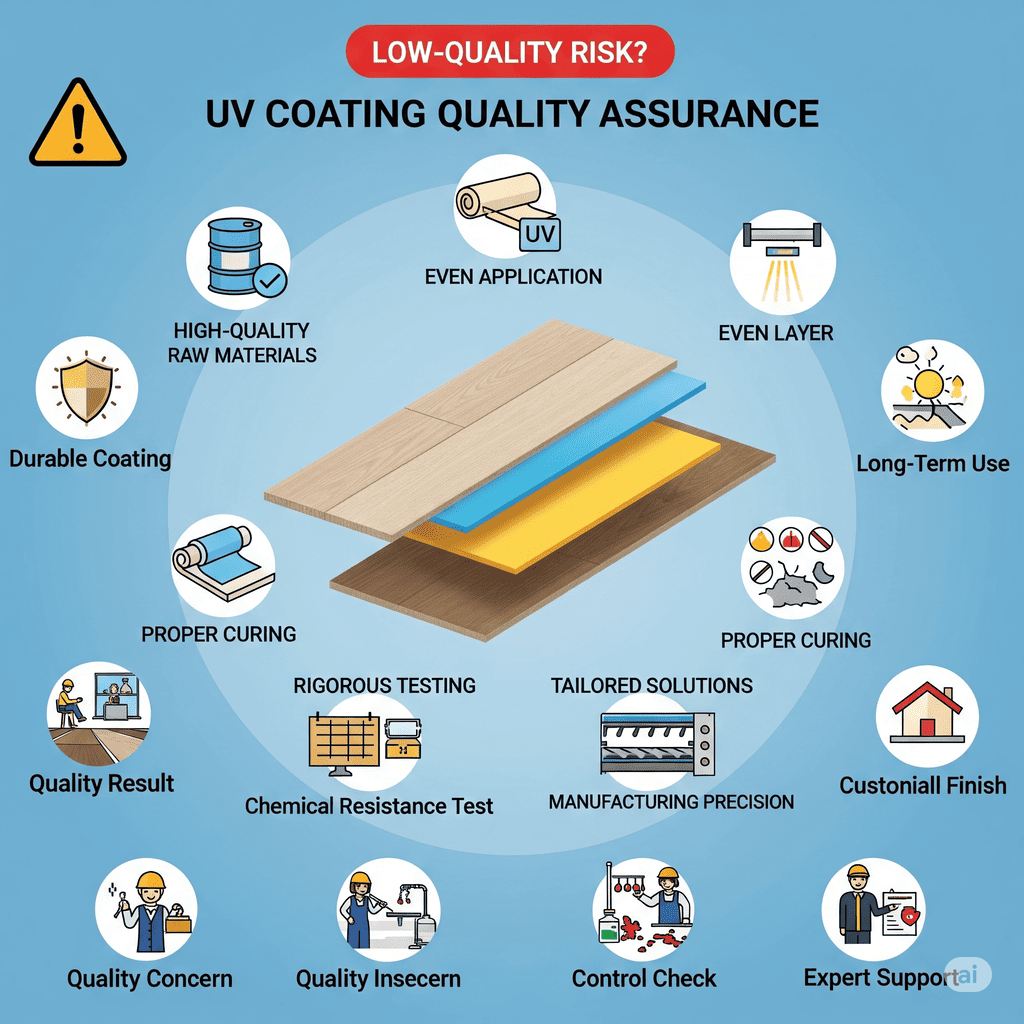

UV coating quality is ensured through strict raw material selection, precise application processes, and thorough curing. Factories must perform consistent quality control checks, including adhesion, abrasion, and stain resistance tests. Reputable suppliers provide test reports.

Strict Formulation and Application

Ensuring UV coating quality1 starts at the very beginning. We choose only the best raw materials for our coatings. This means working with trusted chemical suppliers. We check their materials for purity and consistency. If the basic components are not good, the final coating will not be good. This is a non-negotiable step for us.

Our UV coatings are engineered with specific chemical compositions. This makes them resistant to UV rays, scratches, and other damage. For instance, alumina crystals improve wear and chemical resistance. We use precise application methods, like roll coating. This ensures the coating spreads evenly. An even layer means reliable protection.

Durability Testing and Customization

After applying and curing the coating, we do many rigorous tests. We check its resistance to scratches, scuffs, stains, and abrasions. These tests make sure our flooring can handle heavy traffic. They also ensure it keeps its good look over time.

We can also customize UV coatings. This means we meet specific durability goals or aesthetic needs, like a high-gloss or matte finish. This customization helps the flooring perform perfectly in its intended environment.

Our decades of experience help us develop energy-cured coatings that meet global safety and sustainability standards. We focus on reducing emissions and energy use. In some cases, UV coatings might need reapplication. This helps keep their protective qualities, especially in areas with a lot of sunlight.

| Quality Control Test | Purpose | Standard Outcome (Good Quality) |

|---|---|---|

| Abrasion Test | Measures resistance to scratching and wear | High cycles before wear |

| Stain Resistance | Checks ability to resist common stains | No visible stain after cleaning |

| Adhesion Test | Ensures coating bonds well to base | No peeling or delamination |

| Gloss Level Check | Confirms consistent sheen | Even gloss across surface |

| Visual Inspection | Checks for defects, bubbles, unevenness | Smooth, clear, defect-free |

| Customization | Tailored for specific needs and aesthetics | Meets client’s specific requirements |

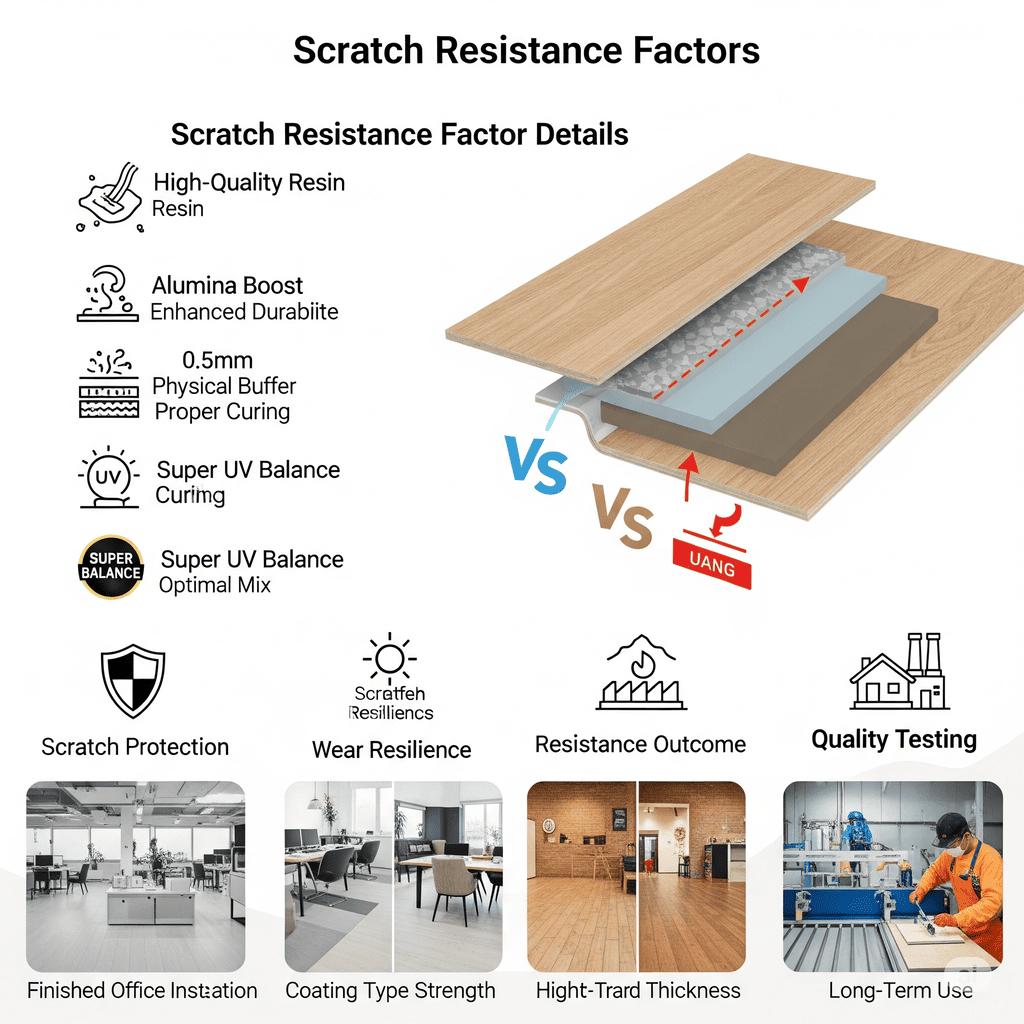

Does coating type or thickness improve scratch resistance more?

Are you wondering what makes a floor truly scratch-proof? Is it the coating material or how thick it is? Many buyers get these mixed up.

Coating type, specifically its chemical makeup, improves scratch resistance more than just thickness. A high-quality, durable resin in a thinner layer can perform better than a thick layer of a weaker material. While thickness adds some protection, the intrinsic hardness of the material is key.

The Role of Coating Type (Chemical Composition)

The type of resin used in the UV coating is very important. Some resins are naturally harder and more resistant to scratches than others. For example, coatings with alumina particles are known for their high scratch resistance. These tiny hard particles act like a shield. They deflect sharp objects. I always recommend looking into the specific type of UV coating material a factory uses. This tells you a lot about its real strength. Our Super UV coatings, for instance, are specially formulated for enhanced resistance.

The Impact of Thickness

While thickness plays a role, it is secondary to the coating type. A thicker coating can provide a bit more cushion against impact. It can also extend the wear life if the top surface wears away slowly.

However, if the material itself is soft, adding more of it will not make it hard. Imagine a thick layer of rubber versus a thin layer of steel. The steel, even thin, is much harder to scratch.

We aim for an optimal thickness that balances protection with cost efficiency. For example, a 0.5mm wear layer will outperform a 0.33mm one in resisting scratches, simply because it offers a stronger physical barrier.

Balance of Type and Thickness

The best scratch resistance comes from a combination. It is a high-quality, hard-wearing coating material. Then, it is applied at an optimal thickness. This ensures maximum protection.

This balance is what separates average flooring from top-tier products. This is what we focus on at CloudsFlooring. We test different types and thicknesses to find the best mix for our products. We find that thickness often has a slight edge in physical resistance, but a high-quality coating type can greatly amplify this benefit. Both factors matter for the best outcome.

| Factor | Primary Impact on Scratch Resistance | Secondary Impact on Scratch Resistance |

|---|---|---|

| Coating Type/Resin1 | Determines inherent hardness | Influences overall durability |

| Added Fillers | Hard particles (e.g., Alumina) add strength | Can increase density, adding minor protection |

| Coating Thickness | Provides a physical buffer, stronger barrier | Less impact than material hardness |

| Curing Quality2 | Ensures full hardness and integrity | Crucial for the coating to perform its best |

| Super UV | Advanced formulation for enhanced resistance | Often combines with optimal thickness |

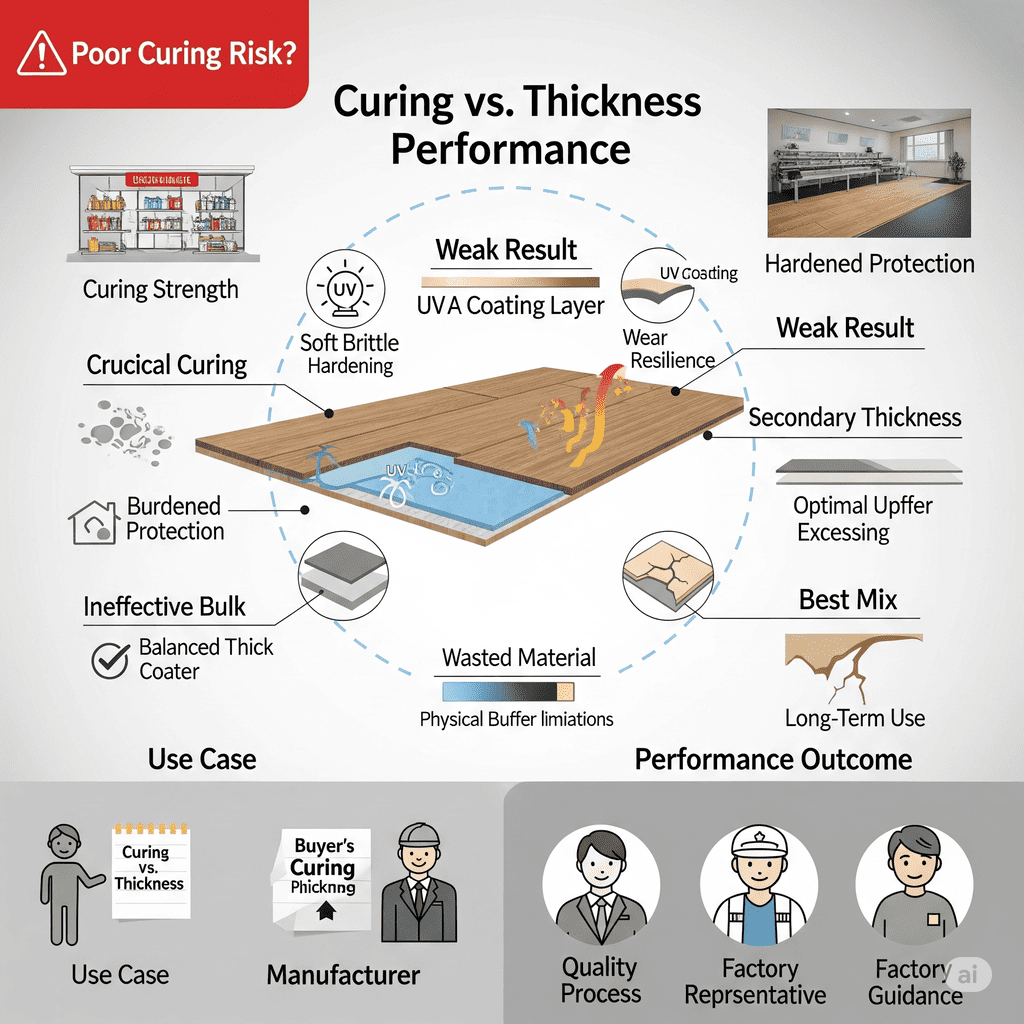

Is coating thickness or curing quality more crucial?

Are you stuck deciding between a thick coating and proper curing? Which one truly matters most? It is a common question for buyers.

Curing quality is more crucial than coating thickness for vinyl flooring performance. A perfectly cured, thinner coating is far more effective than a thick, poorly cured one. Proper curing fully hardens the coating, ensuring its chemical properties deliver maximum scratch, stain, and wear resistance.

The Fundamental Role of Curing Quality

Curing is the process that changes the liquid UV coating into a solid, protective layer. If the curing is not complete or even, the coating will not fully harden. It will remain soft in spots or become brittle. This means it will not provide the protection it should. It will scratch easily. It will also pick up stains fast. It might even peel off the floor. I cannot stress enough how important this step is. It is the backbone of the coating’s performance. Proper UV curing allows for instant hardening. This is a big advantage over old finishes that took days to dry. Poor curing can damage even thick coatings.

Limits of Coating Thickness

Thickness can add some benefits, but it has limits. If the coating is not fully cured, adding more thickness just means more soft material. It is like trying to build a strong wall with wet cement. No matter how much cement you use, if it does not dry properly, the wall will be weak.

A very thick coating can also cause other problems. It can make the floor look odd. It might even crack over time if it is too thick and inflexible. While thicker coatings add physical durability against wear and scratches, this only matters if the coating is properly hardened.

Optimal Balance

The best result comes from a precise balance. This means using the right coating material at an optimal thickness. Then, it is critical to ensure perfect curing. This combination gives the strongest, most durable surface.

We use advanced UV lamps and precise controls. This ensures every square meter of our flooring has a perfectly cured, hard-wearing surface. This attention to detail is what gives our buyers peace of mind. Curing quality is more foundational. It makes sure the coating works as it should. But thickness is essential for achieving high durability in real-world use. Both must be managed well for the best outcome.

| Aspect | Impact on Performance (Poor) | Impact on Performance (Good) |

|---|---|---|

| Poor Curing Quality | Soft spots, brittle, peels, low scratch resistance | Coating fully hardens, strong chemical bonds, maximum protection |

| High Thickness (Poor Curing) | Still weak, uneven, might crack, waste of material | Not applicable, thickness is not a substitute for curing |

| Good Curing Quality | Ensures chemical properties are activated, hard surface | Maximizes scratch, stain, wear resistance, long lifespan |

| Optimal Thickness | Efficient use of material, good feel | Provides a good protective layer without excessive cost |

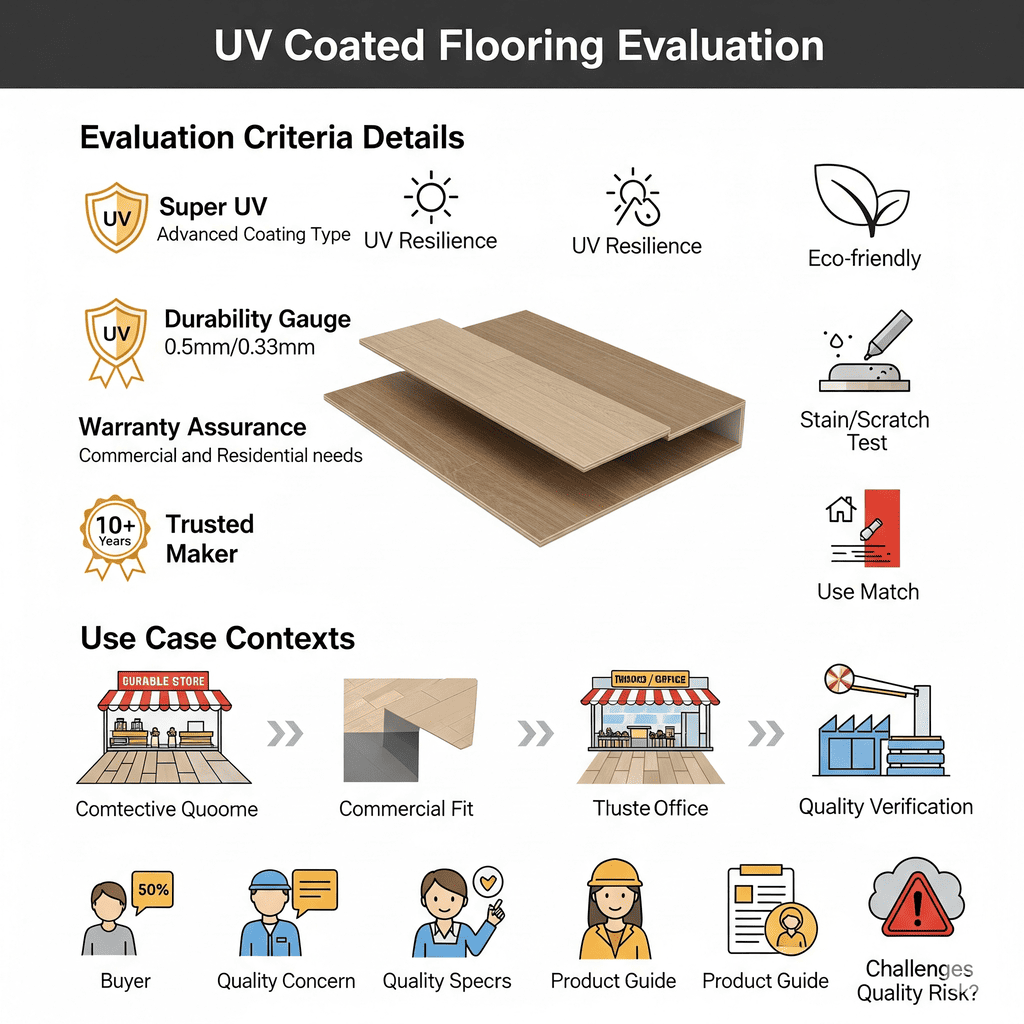

How should buyers evaluate UV coated flooring?

Are you unsure how to check the quality of UV coated flooring? Do you want to avoid costly mistakes? Many buyers face this challenge.

Buyers should evaluate UV coated flooring by asking for detailed product specifications, including coating type and thickness. Request test reports for abrasion and stain resistance. Visually inspect samples for clarity and evenness. Look for suppliers with transparent processes and strong quality control.

Key Evaluation Criteria for Buyers

When you select UV-coated vinyl flooring, you should consider many factors to make sure it lasts and performs well. First, ask about the UV coating specifications. See if the flooring has advanced UV coatings, like "Super UV" wear layers. These offer better scratch, wear, and stain resistance.

Second, check the wear layer thickness1. For commercial use, a 0.5mm layer is better. For homes, 0.33mm might be fine. Thicker layers mean more durability in busy areas.

Third, look for long warranties. A 10-year commercial warranty shows high quality. It covers wear and water resistance. Fourth, research the manufacturer’s reputation. Choose brands that have a good history with UV coating technology.

Practical Testing and Environmental Impact

You can also do practical tests. Try writing on a sample with a permanent marker. Then, wipe it clean. This shows how well it resists stains. It also shows its scratch resistance.

Next, think about where you will use the flooring. Commercial spaces need thicker, stronger coatings than homes. Finally, consider the environment. Choose eco-friendly coatings that are free of volatile organic compounds (VOCs). This is better for indoor air quality and the planet. These steps help buyers make smart choices when buying UV-coated vinyl flooring.

| Criteria | Details |

|---|---|

| UV Coating Specs | Look for "Super UV" or advanced coatings for enhanced durability. |

| Wear Layer Thickness | 0.5mm for commercial, 0.33mm for residential; thicker is more durable. |

| Warranty | Longer warranties (e.g., 10 years) indicate quality; check coverage. |

| Manufacturer | Choose reputable brands with UV coating expertise. |

| Testing | Test with a permanent marker to confirm stain/scratch resistance. |

| Intended Use | Match thickness and coating type to traffic level (e.g., home vs. office). |

| Environmental Impact | Prefer VOC-free coatings for eco-friendliness. |

Conclusion

UV coating is key for durable vinyl flooring. It provides protection against wear, stains, and fading. Focus on quality materials and proper curing, not just thickness. Always ask for clear data and inspect samples.

The above data is for reference only.