Are you feeling overwhelmed by varied SPC flooring quotes? Many buyers find it tough to compare them fairly. This can cause frustration and lead to poor decisions.

Fairly comparing SPC flooring quotes requires looking beyond the sticker price. Focus on core specifications, total transaction costs, certifications, and manufacturer reputation for true value. This approach helps ensure an apples-to-apples comparison for your business.

I know how challenging it can be to navigate the global market for flooring. At CloudsFlooring, we have seen many buyers struggle with comparing different offers. It is more than just the numbers on the page; it is about understanding what those numbers truly represent.

Beyond the per-square-foot price, what core SPC flooring specifications (e.g., thickness, wear layer, core density, locking system) truly define value, and how do buyers ensure a fair, apples-to-apples comparison?

Are you only looking at the per-square-foot price? This can be misleading. Focusing only on this number can hide key differences in product quality and longevity.

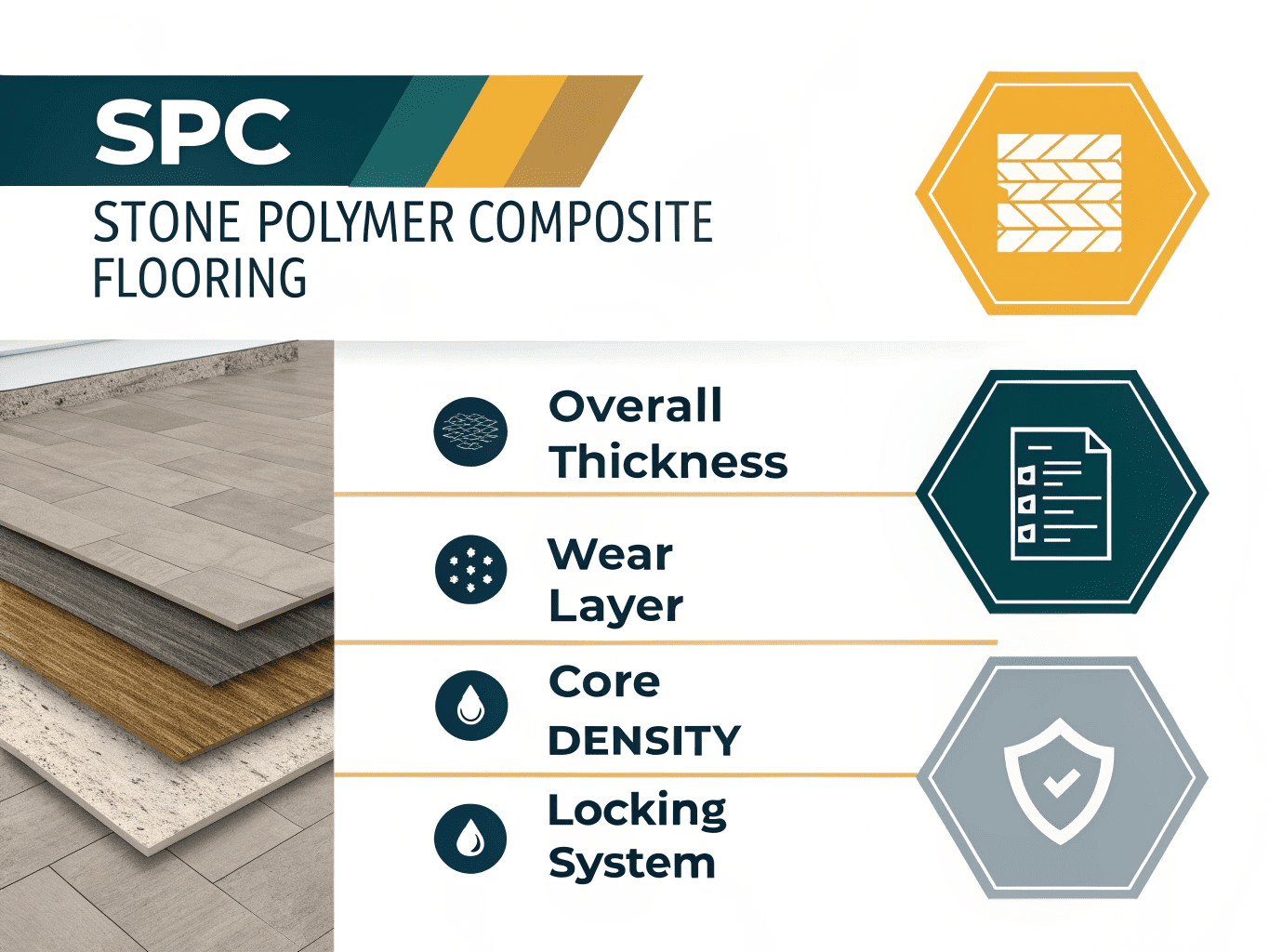

Value in SPC flooring goes deeper than price. Key specifications like overall thickness, wear layer, core density, and locking system significantly impact durability and performance, ensuring an apples-to-apples comparison. Understanding these specs helps you buy smart.

When I talk to buyers like Aiden from the UK, who focuses on LVT but has similar concerns about quality, I always stress the importance of understanding product specifications. A lower price might mean a thinner wear layer or a less dense core. This can lead to faster wear and tear, which ultimately costs you more. For example, at CloudsFlooring, we always highlight the specific details of our LVT and SPC products.

Key SPC Flooring Specifications to Compare

- Overall Thickness: This refers to the entire plank’s thickness. Thicker planks often feel more stable and durable. Common thicknesses range from 3.5mm to 6.0mm.

- Wear Layer: This is the transparent top layer protecting the floor from scratches and wear. It is measured in mils (thousandths of an inch). A thicker wear layer (e.g., 12 mil vs. 20 mil) means better durability. For commercial use, I recommend 20 mil or higher.

- Core Density: This refers to the density of the Stone Plastic Composite core. A denser core provides better indentation resistance and stability. This is crucial for heavy traffic areas.

- Locking System: A good locking system ensures planks click together tightly and stay connected. Look for reputable systems like Unilin or Valinge. A weak system can lead to gaps or separation over time.

How Specifications Impact Value

| Specification | Low Quality (Lower Price) | High Quality (Higher Price) | Impact on Value |

|---|---|---|---|

| Overall Thickness | 3.5mm – 4.0mm | 5.0mm – 6.0mm | Better stability, less subfloor imperfection show |

| Wear Layer | 6 mil – 12 mil | 20 mil – 30 mil | Much higher scratch/wear resistance, longer lifespan |

| Core Density | Lower gram/m³ | Higher gram/m³ | Superior indentation resistance, better stability |

| Locking System | Generic/Less reliable | Branded/Patented | Easier installation, prevents gapping, stronger hold |

I always advise buyers to ask for detailed specification sheets. Do not just take a sales representative’s word. Look for a factory that can provide test reports and samples to verify these specifications. This careful review ensures you are truly comparing similar products, not just similar prices.

How can buyers comprehensively evaluate and calculate the "total transaction cost" in SPC flooring quotes, including elements like packaging, shipping (FOB port costs), and Minimum Order Quantity (MOQ)?

Many buyers overlook hidden costs. This can impact your profit margins significantly. Failing to account for these elements can turn a seemingly good deal into a costly mistake.

Calculating total transaction cost1 means considering all elements. Packaging, shipping (FOB port costs), and Minimum Order Quantity (MOQ) significantly impact the final price per unit, requiring careful evaluation of all quote components to ensure you get the best deal overall.

When I prepare a quote at CloudsFlooring, I always make sure to break down all the costs clearly. From my experience, what seems like a low unit price can quickly escalate when you add in all the other necessary charges. Lori, a COO from the United States, once shared how a low initial quote turned expensive due to unexpected shipping and packaging fees.

Elements of Total Transaction Cost

- Product Unit Price: This is the per-square-foot or per-square-meter price of the flooring itself. This is often the first number buyers see.

- Packaging Costs: This includes the cost of cartons, pallets, and any specialized packaging for protection during transit. Some suppliers might include this in the unit price, others list it separately. Ensure it is clear.

- Shipping (FOB Port Costs): This refers to "Free On Board" costs at the origin port. It includes local trucking, customs clearance at the factory’s country, loading onto the vessel, and documentation. This is a significant part of your cost when importing. You need to know which port it ships from.

- Minimum Order Quantity (MOQ): While not a direct cost, MOQ impacts your unit price. If a supplier has a high MOQ and you buy less, they might increase the unit price. Or, if you need to buy more than you planned to meet the MOQ, you incur inventory holding costs. We at CloudsFlooring offer flexible MOQs to help our B2B clients manage this.

- Payment Terms: Consider the impact of payment terms on your cash flow. A supplier requiring 100% upfront might be cheaper per unit, but ties up capital. A 30% deposit, 70% against B/L offers better cash flow management.

Calculating Your True Cost

To get a true "cost landed" price, you must add all these elements together. For example, if you are buying 10,000 square meters of SPC flooring:

- Product price: $5.00/sqm = $50,000

- Packaging: $0.10/sqm = $1,000

- FOB Port Costs: $500 (flat fee)

- Total FOB Cost: $50,000 + $1,000 + $500 = $51,500

- True Unit Cost (FOB): $51,500 / 10,000 sqm = $5.15/sqm

Understanding these components helps you avoid surprises and plan your budget accurately. Always ask for a detailed breakdown of all costs included in the quote, and clarify what is NOT included, such as destination port charges, customs duties in your country, and local delivery.

Beyond the direct price and explicit fees, how do factors like international certifications, product quality consistency, and warranty terms from manufacturers impact wholesalers’ market access and mitigate commercial risks?

Direct price is not the only risk factor. Certifications protect your business. Overlooking these critical elements can lead to significant problems down the line, affecting your sales and reputation.

International certifications, consistent product quality, and clear warranty terms are crucial. These factors ensure market access, build customer trust, and mitigate commercial risks for wholesalers, safeguarding your reputation and bottom line against unexpected issues.

At CloudsFlooring, I often see the real impact of quality consistency. We know that buyers like Aiden from the UK face issues with suppliers falsifying certificates. This is why we prioritize transparent certifications and strict quality control. A few years ago, I dealt with a buyer who received a batch of flooring that did not match the initial sample. This caused a huge headache for them and damaged their end-customer relationships.

Crucial Factors Beyond Price

- International Certifications: These are third-party verifications that a product meets specific standards. For SPC flooring, look for certifications like:

- CE (Conformité Européenne): Mandatory for sales in the European Economic Area.

- FloorScore/GreenGuard: For indoor air quality, indicating low VOC emissions. This is important for health and safety.

- ISO 9001: Certifies the manufacturer’s quality management system. This means their production processes are structured and consistent.

- ASTM (American Society for Testing and Materials): Important for North American markets, covering various performance tests.

Always ask for copies of these certificates and verify their validity.

- Product Quality Consistency: It is one thing to get a good sample, but another to receive consistent quality across an entire order or multiple orders. Ask about the factory’s quality control process, including pre-production checks, in-process inspections, and final product testing. As a factory with two SPC and three LVT lines, we implement stringent checks at every stage.

- Warranty Terms: A manufacturer’s warranty reflects their confidence in their product. Understand what the warranty covers (e.g., wear, manufacturing defects), its duration (residential vs. commercial), and the claims process. A clear and strong warranty protects you and your customers.

Risk Mitigation Strategies

| Factor | Risk if Not Considered | Mitigation Strategy |

|---|---|---|

| Certifications | Market access issues, legal penalties | Request valid certificates, verify authenticity |

| Quality Consistency | Returns, reputation damage, lost sales | Demand QC reports, conduct pre-shipment inspections |

| Warranty Terms | Unforeseen costs, customer disputes | Review warranty clearly, understand claims process |

By focusing on these aspects, wholesalers can build trust with their customers and avoid the high costs associated with product failures, returns, or legal issues. It is about building a reliable supply chain.

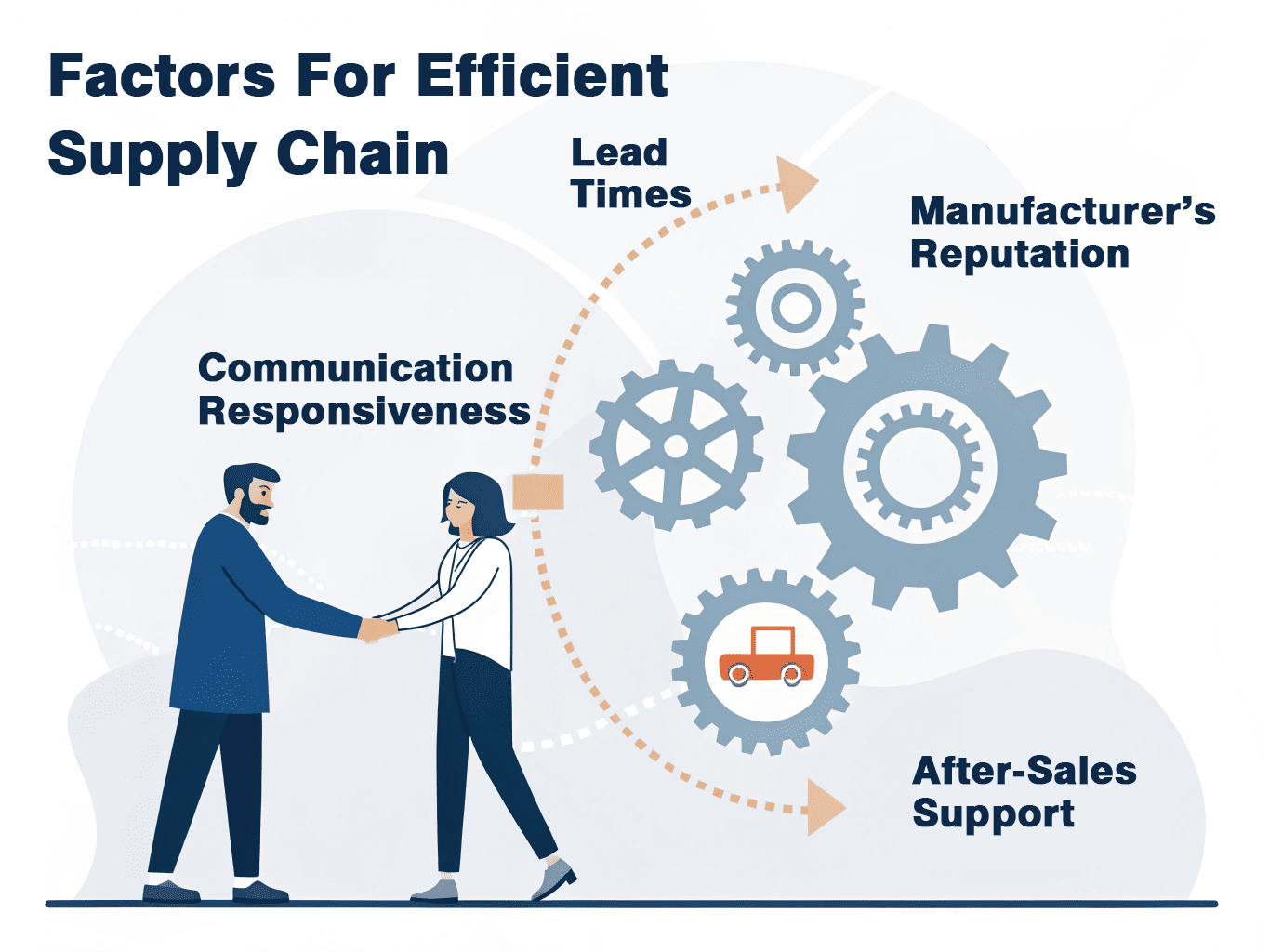

How do the manufacturer’s reputation, lead times, communication responsiveness, and after-sales support directly influence wholesalers’ supply chain efficiency and long-term strategic partnerships?

A low price means nothing with poor service. Strong partnerships are key to your success. Poor communication or delays can quickly erode profits and damage customer relationships.

A manufacturer’s reputation, reliable lead times, clear communication, and strong after-sales support directly impact supply chain efficiency. These elements are vital for building trust and establishing successful, long-term strategic partnerships with wholesalers, ensuring smooth operations and growth.

As a factory owner, I understand the critical role of these factors. At CloudsFlooring, we pride ourselves on being responsive and transparent. I remember a time when Lori, our US client, faced a tight deadline. Our clear communication and on-time delivery helped her avoid missed sales seasons, which is a common pain point for buyers. Aiden also mentioned how inefficient communication with suppliers often caused him problems.

Factors for Efficient Supply Chain

- Manufacturer’s Reputation1: A good reputation means reliability and trust. Look for reviews, testimonials, and industry recognition. Ask for references from other buyers. A strong reputation suggests consistent quality and ethical business practices.

- Lead Times2: This is the time from order confirmation to shipment. Unrealistic lead times can lead to delayed shipments and missed selling seasons, impacting your profitability. A reliable manufacturer provides realistic lead times and adheres to them. We always provide clear production schedules at CloudsFlooring.

- Communication Responsiveness3: How quickly and clearly does the manufacturer respond to your inquiries? Effective communication prevents misunderstandings and resolves issues fast. This includes updates on production status, shipping, and any potential delays. Good communication is a hallmark of a strong partner.

- After-Sales Support: What happens if there is an issue after delivery? Good after-sales support means the manufacturer stands by their product and helps resolve problems like quality discrepancies or shipping damage. This builds long-term trust and peace of mind.

Impact on Wholesaler Operations

| Factor | Impact on Supply Chain Efficiency | Impact on Strategic Partnerships |

|---|---|---|

| Reputation | Reliable product source, less risk | Builds trust, preferred partner |

| Lead Times | Predictable inventory, timely delivery | Meets customer demand, avoids lost sales |

| Communication | Fast issue resolution, clarity | Stronger relationship, mutual understanding |

| After-Sales Support | Reduces claims, supports end-customers | Demonstrates commitment, fosters loyalty |

Choosing a manufacturer based on these operational factors ensures a smoother, more efficient supply chain. This approach builds strong, lasting partnerships that contribute significantly to your business growth and competitive edge in the market.

Conclusion

Fairly comparing SPC flooring quotes means looking beyond price. Focus on specs, total costs, certifications, and supplier reliability. This leads to better decisions and stronger partnerships.

The above data is for reference only.

-

Understanding the significance of a manufacturer’s reputation can help you choose reliable partners, ensuring quality and trust in your supply chain. ↩ ↩

-

Exploring lead times will provide insights into how they impact your business operations and help you avoid costly delays. ↩

-

Learning about communication responsiveness can enhance your partnerships and streamline operations, leading to better outcomes. ↩