Facing product quality issues in your flooring business? SPC flooring can be durable, but problems arise if expectations are unclear. Learn to prevent these issues and ensure lasting quality.

For importers, setting clear quality expectations through detailed QC checklists, purchase orders, and vendor agreements is crucial to prevent SPC flooring problems from the start. This proactive approach ensures your supplier understands exactly what you need.

Getting the right quality for your SPC flooring starts with understanding what is acceptable. This means setting clear standards with your manufacturer from day one. As a factory in China, we know how important it is to align on every detail.

What are the problems with SPC flooring?

SPC flooring is durable, but problems can surface. Are you facing scratches, discoloration, or installation headaches? Knowing these issues helps you find solutions.

Common SPC flooring problems include surface issues like scratches, scuffs, discoloration, and fading. Other issues involve moisture damage causing swelling or warping, loose or gapping planks due to improper installation, and physical damage like dents or indentations.

As a factory with extensive experience, I see recurring problems affecting SPC flooring quality. Quality issues lead to complaints and brand damage, even though SPC is durable.

Clients often face surface damage. Scratches and scuffs happen from heavy furniture or high traffic. Discoloration and fading also occur due to sun exposure or harsh cleaners.

Structural issues are also critical. SPC is water-resistant, but moisture can still cause swelling or warping. This happens if water enters seams or subfloor moisture is unmanaged.

Loose or gapping planks are common. This usually results from improper installation or temperature changes. Dents and indentations show that even a rigid core can be damaged by heavy objects. More severe problems like buckling or warping come from insufficient expansion gaps or too much moisture.

My experience traces these issues back to inaccurate manufacturing. This includes improper mold calibration, uneven raw material mixing, or insufficient cutting precision. Poor quality control, like dust contamination or inadequate packaging, can also cause surface defects. Understanding these helps us develop better prevention.

| Common SPC Flooring Problems | Description | Primary Causes | Initial Impact on Product |

|---|---|---|---|

| Scratches & Scuffs | Surface marks and abrasions. | Heavy furniture, high traffic, abrasive cleaning. | Aesthetic degradation, reduced appeal. |

| Discoloration & Fading | Color change or loss of vibrancy. | Prolonged UV exposure, harsh cleaning agents. | Uneven color, dull appearance. |

| Moisture Damage (Swelling/Warping) | Planks absorb moisture, expand, and deform. | Water spills/leaks, high humidity, unsealed subfloors. | Structural instability, separation of planks. |

| Loose/Gapping Planks | Planks separate, creating visible gaps. | Improper installation, temperature fluctuations, uneven subfloors. | Unsafe walking surface, aesthetic issues. |

| Dents & Indentations | Depressions in the flooring surface. | Heavy objects dropped/dragged, improper cleaning tools. | Permanent marks, uneven surface. |

| Buckling & Warping | Floors lift or distort significantly. | Improper acclimation, insufficient expansion gaps, excessive moisture. | Major installation failure, requires replacement. |

| Locking System Issues | Planks do not interlock securely. | Inaccurate mold design, improper pressure/temperature during production. | Loose planks, cracking, installation failure. |

| Dimensional Inconsistencies | Variations in length, width, or thickness. | Improper mold calibration, uneven material mixing, insufficient cutting precision. | Installation difficulties, uneven seams. |

What is the quality of SPC flooring?

Need durable, reliable flooring? Judging SPC quality is key. Many claims exist, but knowing true indicators helps your business source the best.

High-quality SPC flooring features a rigid core for superior stability and dent resistance, a thick and durable wear layer for scratch protection, and a precise click-lock system for secure, waterproof installation. It also meets rigorous international performance, safety, and indoor air quality standards.

As a manufacturer at CloudsFlooring, SPC flooring quality depends on key attributes. These ensure long-term performance and appeal for our clients.

First, the core construction is crucial. High-quality SPC uses a rigid core made from virgin PVC, limestone powder, and stabilizers. This composition gives it exceptional stability and dent resistance. Core density is often 1900-2000 kg/m³, with 2000+ PSI ratings. This sets it apart from other vinyl products.

Secondly, the wear layer is vital for durability. A top-quality SPC plank has a robust wear layer, typically 0.3mm or 0.5mm thick. It is infused with UV-cured urethane and ceramic particles. This enhances scratch and scuff resistance. This layer ensures the floor looks good under heavy commercial use.

Thirdly, the locking system integrity is non-negotiable. Systems like Valinge 2g Click ensure secure, glueless floating installations. They provide tight, water-resistant seams and prevent planks from loosening over time. I verify precise locking mold design. Manufacturing processes must also maintain proper pressure and temperature for robust connections.

Furthermore, true SPC quality includes compliance with international standards. ASSURE CERTIFIED™ verifies adherence to North American standards for rigid core flooring. This covers indoor air quality (FloorScore®), performance, and low heavy metal/phthalate content. Meeting standards like ASTM F3261-17 confirms product reliability.

We also ensure our products are dimensionally stable. They maintain flatness within tight tolerances, like 3/16” in a 10’ radius. This prevents unevenness or installation issues. All these factors define a high-quality SPC flooring product I offer.

| Key Quality Indicators for SPC Flooring | Description | Relevant Standards/Features |

|---|---|---|

| Core Construction | Rigid, stable core for dent and impact resistance. | Virgin SPC (2000+ PSI), Core density 1900-2000 kg/m³. |

| Wear Layer | Durable protective layer for scratch and scuff resistance. | Thickness (e.g., 0.3mm or 0.5mm), UV cured urethane with ceramic infusion. |

| Locking System | Precise click-lock mechanism for secure, tight seams. | Valinge 2g Click, Tensile strength & durability tests. |

| Waterproof Properties | Inherently resistant to water, preventing swelling/warping from spills. | Does not prevent moisture transmission from subfloor; requires moisture barrier. |

| Dimensional Stability | Ability to maintain shape and size within specified tolerances. | Flatness within 3/16” in 10’ radius. Jobsite temp 60-80°F, RH 30-60%. |

| Certifications & Compliance | Adherence to industry standards for safety, performance, and air quality. | ASSURE CERTIFIED™, FloorScore®, ASTM F3261-17, CPSC Phthalates, CONEG Heavy Metals. |

What are acceptable tolerances for minor SPC Flooring issues like edge chipping or slight color variations?

Small imperfections worry you in SPC flooring orders? Minor issues can become major. Learn to set clear quality expectations with manufacturers to avoid headaches.

Acceptable tolerances for minor SPC flooring issues, like slight color variations or minor edge chipping, should be clearly defined in your quality control checklist. These are typically small imperfections that do not affect the product’s function or form.

When I work with large company buyers, I know even small cosmetic issues concern them. Minor defects are generally small and insignificant. They do not affect the product’s main use.

For SPC flooring, minor issues include slight color variations. These are standard and create a natural look. They might also involve very light surface abrasions or tiny, non-obvious edge imperfections. These issues typically do not cause customer returns.

However, even "minor" issues need clear definitions. Slight dimensional inconsistencies can lead to uneven seams if not tightly controlled. Minor surface imperfections, like small bubbles or slight color inconsistencies, can impact aesthetics if uncontrolled.

To manage these, we define them clearly in our Quality Control (QC) checklist. This checklist includes precise specifications and often photos. We use Acceptable Quality Limits (AQL)1 to set a tolerance for minor defects per batch. It is crucial to have these detailed standards in writing and agreed upon before production. This prevents misunderstandings.

To ensure these issues remain minor, we set specific parameters with manufacturers. For dimensional consistency2, we require detailed tolerance standards, like ±0.1mm, in our contract. We also conduct regular sampling.

For surface imperfections, we push for high-quality wear layers (0.3mm or 0.5mm thick) and demand material certifications. We advocate for strict cleanroom production to reduce dust and impurities. Improved packaging, using protective films and reinforced packaging, also prevents minor transit damage.

Here is how I approach acceptable tolerances for minor defects:

| Minor Defect Type | Acceptable Tolerance / Standard | Common Causes | Preventative Measures |

|---|---|---|---|

| Slight Color Variation | Mix planks from several cartons for random appearance; uniform color guaranteed only for same production lot. Acceptable within a specified Delta E value. | Natural variations in raw material batches; uneven pigment mixing. | Purchase from same production batch; specify color ranges; conduct pre-installation checks. |

| Edge Chipping (Minor) | Less than 0.5mm depth/length; not visible after installation or affecting locking. | Insufficient precision in cutting; improper handling. | Optimize cutting/calibration; improve packaging. |

| Dimensional Inconsistency (Minor) | Length/width/thickness deviation within ±0.1mm. | Improper mold calibration; uneven shrinkage. | Specify tolerances; random sampling; regular maintenance. |

| Minor Surface Blemishes (e.g., small bubbles/dust) | Less than 0.5mm diameter; not affecting wear layer/visual appeal. | Contamination by dust/impurities. | Implement strict cleanroom production; regular line cleaning. |

By setting these clear benchmarks, we ensure that while some minor variations are inherent to manufacturing, they remain within acceptable bounds for our wholesale clients in North America, the UK, and the Middle East.

How can importers ensure manufacturers have robust QC for locking system integrity to prevent common SPC Flooring Problems?

Is your SPC flooring prone to gapping or buckling? Weak locking systems can ruin an entire installation. Discover how to guarantee strong, reliable click-lock mechanisms in your orders.

Importers can ensure robust QC for SPC flooring locking systems by including specific on-site product tests in their QC checklists, verifying manufacturer’s internal QC procedures through factory audits, and inspecting product samples.

Ensuring SPC flooring locking system integrity is critical for our clients. They prioritize quality and want to avoid differences after receiving goods.

SPC flooring uses click-lock systems3, like Valinge 2g Click. These are for easy, glueless floating installations. If the mechanism is weak, it causes loose or gapping planks and even buckling. Inaccurate design or manufacturing defects lead to planks loosening or cracking. Improper subfloor preparation with excessive movement can also break the mechanism.

To prevent these issues, we implement several QC layers.

- On-site Tests: Our QC checklist includes specific on-site tests for the locking system. During inspection, specialists physically test click engagement and strength. They perform pull tests and durability tests to ensure secure connections. We specify exact testing procedures for consistent results and require strength/installation testing for each batch.

- Factory Audits: Conducting factory audits (QMS audits) is vital. As a factory, we have strict internal QC from raw materials to final product. These audits assess our production capabilities, machine maintenance, and internal lab testing. Machines cutting lock profiles must be precisely calibrated. Calibration issues or poor maintenance directly impact integrity. We also examine production for proper pressure and temperature control, crucial for mechanism manufacturing.

- Product Sample Review: Reviewing product samples is non-negotiable. Before mass production, we provide "golden samples" for client approval. These samples allow hands-on evaluation of locking system quality, ease of installation, and plank fit. This confirms the product meets client standards, preventing surprises upon bulk order arrival.

For SPC, the core composition, like Virgin SPC at 2000+ PSI, is crucial for locking mechanism stability. We ensure raw materials for the core have sufficient strength. By confirming specifications and conducting rigorous tests, we ensure our clients receive top-quality SPC flooring. We ask for tensile strength/durability reports and review lock design drawings for compliance with international standards (ISO or EN).

Here is a summary of our QC measures for locking system integrity:

| QC Measure | Description | How it Helps Locking System QC |

|---|---|---|

| QC Checklist: On-site Tests | Detailed instructions for functional tests at the factory, including pull tests and installation tests. | Specifies physical tests for click mechanism strength and durability. Checks angle at which planks lock (e.g., 20°-30°). |

| Supplier Qualification Audit (QMS) | Assesses factory’s internal QC systems, machine maintenance, lab capabilities, and process control. | Verifies precise calibration of cutting machinery; effective staff training; robust internal testing. Checks proper pressure/temperature. |

| Product Sample Review | Physical inspection of pre-production "golden samples". | Allows direct evaluation of locking system quality, ease of installation, and plank fit. |

| Material Strength Verification | Defines exact material compositions for SPC core layer and density requirements. | Ensures core material has correct rigidity/density (e.g., 1900-2000 kg/m³ for virgin core). |

| Design Drawing Review | Collaboration with manufacturer to review lock design drawings. | Ensures lock design complies with international standards (e.g., ISO or EN). |

Should importers establish clear defect classification criteria with manufacturers before ordering SPC flooring?

Unclear defect standards lead to costly disputes and rejected shipments. Avoid surprises and ensure quality. Learn why clear defect classification is essential for your SPC flooring orders.

Yes, importers absolutely should establish clear defect classification criteria (critical, major, minor) with manufacturers before ordering SPC flooring to manage quality expectations, prevent misunderstandings, and facilitate effective inspections.

I cannot stress enough the importance of establishing clear defect classification criteria1 with manufacturers. This prevents costly issues and ensures the final product meets your quality standards. As a B2B factory, we work closely with large buyers and distributors. Their pain points often relate to communication and quality consistency. Unclear defect definitions lead to misunderstandings and receiving subpar products.

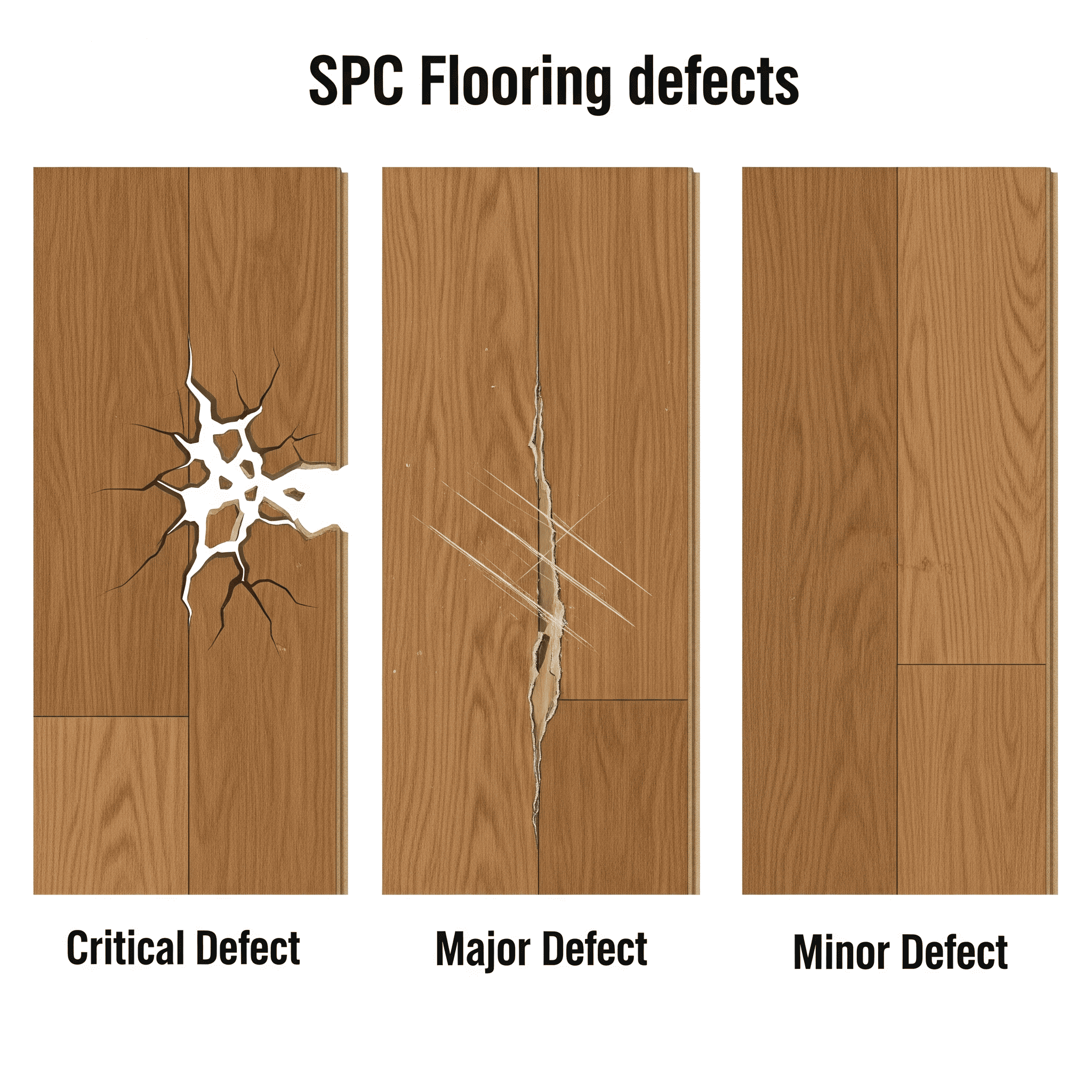

We classify defects into three types: critical, major, and minor.

- Critical defects: Make the product unusable or pose a safety risk (e.g., broken locking mechanism, sharp edges). We aim for zero tolerance.

- Major defects: Significantly affect performance or appearance, likely causing returns (e.g., deep scratches, severe warping, delamination).

- Minor defects: Usually cosmetic, not affecting function (e.g., slight color variations, minor surface imperfections).

Beyond these, we consider broader durability. Poor wear resistance, impact resistance, or inadequate waterproofing shortens lifespan. These often stem from low-quality materials, improper PVC/calcium ratios, or lacking UV coating.

To avoid this, we specify core layer density (e.g., 1900-2000 kg/m³) for strength. We demand chemical analysis for raw materials. We also request extra UV or antibacterial coatings to boost durability and appeal.

To formalize criteria, I use a detailed Quality Control (QC) checklist2. This document outlines every possible defect, often with photos, and specifies acceptable quality levels (AQL). I also include these requirements in the Purchase Order (PO) and Vendor Agreements.

This ensures manufacturers understand standards from the start, before production. Concerns about inefficient communication or false certificates are addressed by clear, legally binding defect criteria. Issues with "quality differences" are tackled by upfront criteria and pre-shipment inspection. This proactive approach helps manufacturers self-correct and ensures inspection results meet our expectations.

Here is how I classify common defects and performance expectations for SPC flooring:

| Defect Category | Definition | Example for SPC Flooring | Impact if Unclassified | Strategies to Set Expectations |

|---|---|---|---|---|

| Critical | Renders item unusable or poses risk of harm. | Broken/non-functional lock; hazardous sharp points. | High recall risk; severe legal/brand damage; total loss. | Zero tolerance in contract; Raw material QC. |

| Major | Adversely affects performance; likely causes return. | Deep scratches; severe warping; delamination; poor impact resistance. | Customer dissatisfaction; high returns; brand damage. | Set AQL for major defects; Monitor material ratios; Regular performance tests. |

| Minor | Insignificant issue; cosmetic; doesn’t affect function. | Slight color variation; small surface blemishes; minor edge chipping. | Minor complaints; perceived lower quality; generally no returns. | Specify aesthetic tolerances; Sample for consistency; Strict cleanroom production. |

| Performance/Durability | Fails lifespan/usage conditions due to flaws. | Insufficient wear resistance; inadequate waterproofing; lack of UV protection. | Shortened lifespan; high warranty claims; loss of trust. | Specify wear layer/core density; UV coating requirements; Sample testing; Market simulation. |

It is crucial to continually update these classifications as new product variations emerge or as market quality demands evolve. Maintaining open communication and building long-term partnerships with manufacturers, providing consistent feedback, helps ensure our SPC flooring always meets the highest standards.

Conclusion

Setting clear expectations with manufacturers through QC checklists and defined defect classifications is key. This proactive approach prevents SPC flooring issues like gapping, ensuring you get top-quality products.

The above data is for reference only.

-

Understanding defect classification criteria can help you avoid costly disputes and ensure product quality in manufacturing. ↩ ↩

-

A well-structured QC checklist is essential for maintaining quality standards and preventing defects in production. ↩ ↩

-

Click-lock systems simplify installation and enhance durability, making them a popular choice for SPC flooring. Learn more about their advantages. ↩