Are you frustrated by constantly changing flooring trends and needing to understand rigid core’s impact? Ignoring these shifts risks missing out on profitable opportunities and falling behind competitors. Discover the essential insights you need right here.

Rigid core flooring, including SPC and WPC, has evolved significantly with enhanced durability, water resistance, and easier installation. Its key advantages are superior stability and less subfloor preparation. For importers, staying current on these trends, like improved visuals and sustainability, is vital for market success.

As a factory owner in China, I see firsthand how quickly the flooring market changes. Understanding these evolutions in rigid core flooring helps me guide my customers. This includes buyers like Aiden from the UK or Jessie from the US. My goal is to help them make smart buying choices.

Rigid core flooring is a type of luxury vinyl flooring. It is popular because it is durable and versatile. It has a strong core layer. This makes it good for many places, from homes to businesses. Let us dive into what makes rigid core so important today.

What are the key differences among Rigid Core flooring types?

Are you confused by the different types of rigid core flooring1 and what makes them unique? Not knowing these distinctions can lead to ordering the wrong product. Let us clarify which type best fits your market needs.

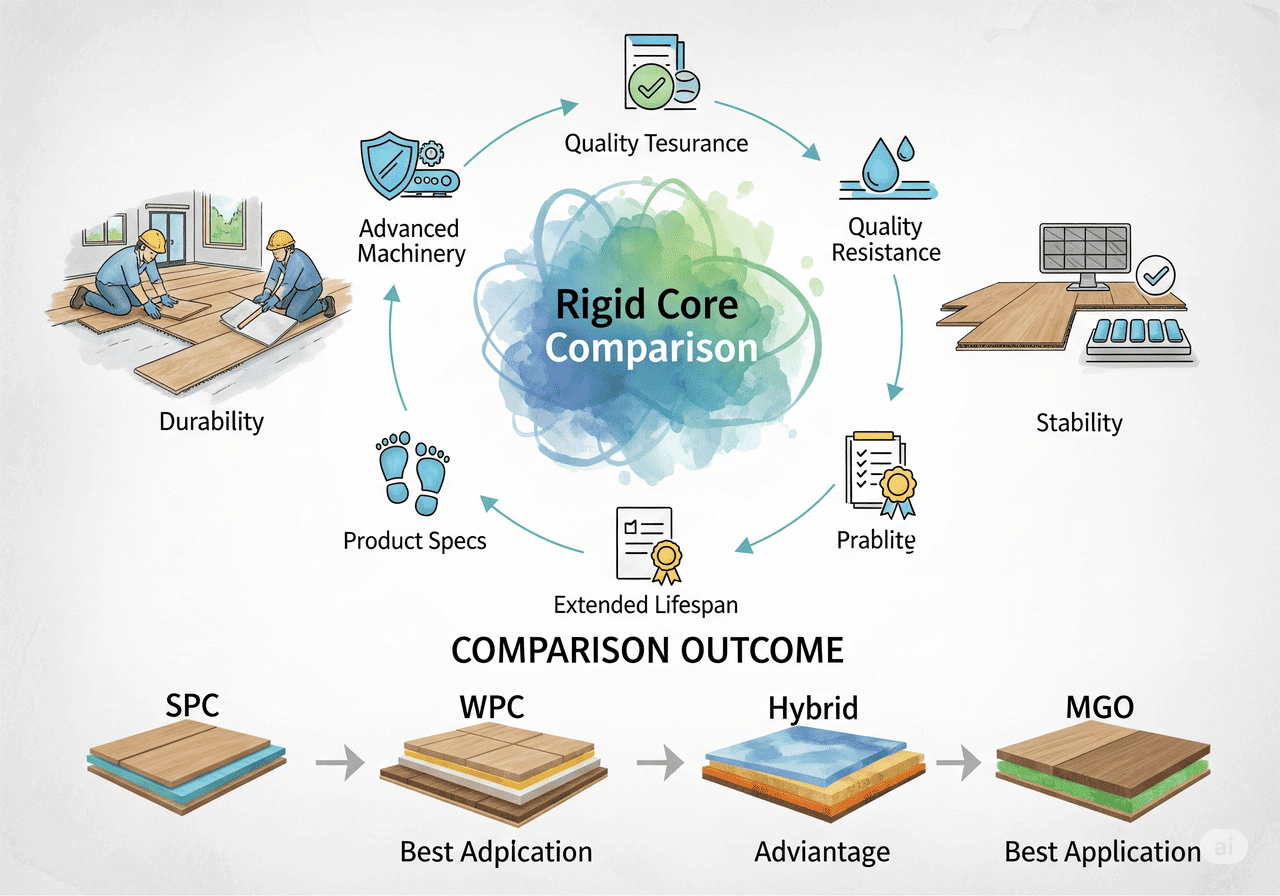

The main rigid core flooring types are SPC (Stone Plastic Composite) and WPC (Wood Plastic Composite). SPC is denser, more rigid, and extremely durable due to its stone powder core. WPC has a wood plastic composite core, making it slightly softer, warmer, and quieter underfoot.

From my experience at CloudsFlooring, helping buyers choose between SPC and WPC is a common task. Both are types of LVT (Luxury Vinyl Tile) or LVP (Luxury Vinyl Plank) with rigid cores. Rigid core flooring has multiple layers. It typically includes a wear layer, a design layer, a rigid composite core, and often an attached underlayment. The main differences among these types come from the core material. This greatly changes how the floor performs, how long it lasts, and where it can be used.

Here are the main types:

-

Stone Polymer Composite (SPC):

- Core Composition: This core is made from crushed limestone or stone mixed with plastic resin. This creates a very dense and rigid core.

- Key Characteristics: SPC is known for being extremely durable and stable. It resists dents, scratches, and moisture well. It is 100% waterproof. This makes it perfect for places with high moisture, like bathrooms, kitchens, and basements.

- Advantages: It offers very good stability and needs little maintenance. It works well in places with heavy foot traffic. It also resists expansion or contraction from temperature or humidity changes.

- Drawbacks: It can feel harder underfoot compared to other types. This might make it less comfortable in homes.

- Our SPC production lines in China make high-quality products. They meet strict international standards. Buyers like Jessie, who prioritize quality control, appreciate this.

-

Wood Polymer Composite (WPC):

- Core Composition: This core combines wood fibers with plastic resin. It is a bit less dense than SPC.

- Key Characteristics: WPC is also 100% waterproof and durable. But it gives a softer, more cushioned feel underfoot. This makes it more comfortable for home use.

- Advantages: It balances durability with comfort. It looks and feels like natural wood. It works well in places with moderate traffic.

- Drawbacks: It is less stable than SPC. This can lead to some expansion or contraction if temperatures or humidity change.

- We pay close attention to material quality. This makes sure both SPC and WPC products meet the specs. This helps avoid quality issues after buyers receive the goods.

-

Hybrid Vinyl:

- Core Composition: This type blends features from laminate and vinyl. It often has a composite core that mixes elements of both.

- Key Characteristics: Hybrid flooring balances laminate’s stiffness and vinyl’s water resistance. This makes it versatile for many uses.

- Advantages: It combines the nice look of laminate with the waterproof qualities of vinyl. This makes it good for both homes and businesses.

- Drawbacks: It might not be as durable as SPC in very busy areas or extreme conditions.

-

Magnesium Oxide (MGO) Core:

- Core Composition: This core uses magnesium oxide. This material is very durable and resists fire.

- Key Characteristics: MGO cores are not as common. But they offer extreme durability and fire resistance. This makes them good for special uses.

- Advantages: It has great strength and resists environmental factors.

- Drawbacks: It costs more and is less available compared to SPC and WPC.

Here is a comparison of rigid core flooring types:

| Type | Core Material | Key Advantages | Key Drawbacks | Best Applications |

|---|---|---|---|---|

| SPC | Limestone + Plastic Resin | High durability, 100% waterproof, very stable | Harder underfoot | High-traffic, wet areas (e.g., bathrooms) |

| WPC | Wood Fibers + Plastic Resin | Comfortable, waterproof, natural look | Less stable than SPC | Residential, moderate traffic |

| Hybrid | Laminate + Vinyl Composite | Versatile, balanced durability and comfort | Less durable than SPC in extreme conditions | Mixed residential/commercial |

| MGO | Magnesium Oxide | Extreme durability, fire-resistant | Higher cost, less common | Specialized, high-risk areas |

How does Rigid Core flooring simplify installation and subfloor preparation?

Are you worried about complex flooring installations and extensive subfloor work adding to your project costs? Traditional flooring often requires significant effort and time. This can lead to delays and increased labor expenses.

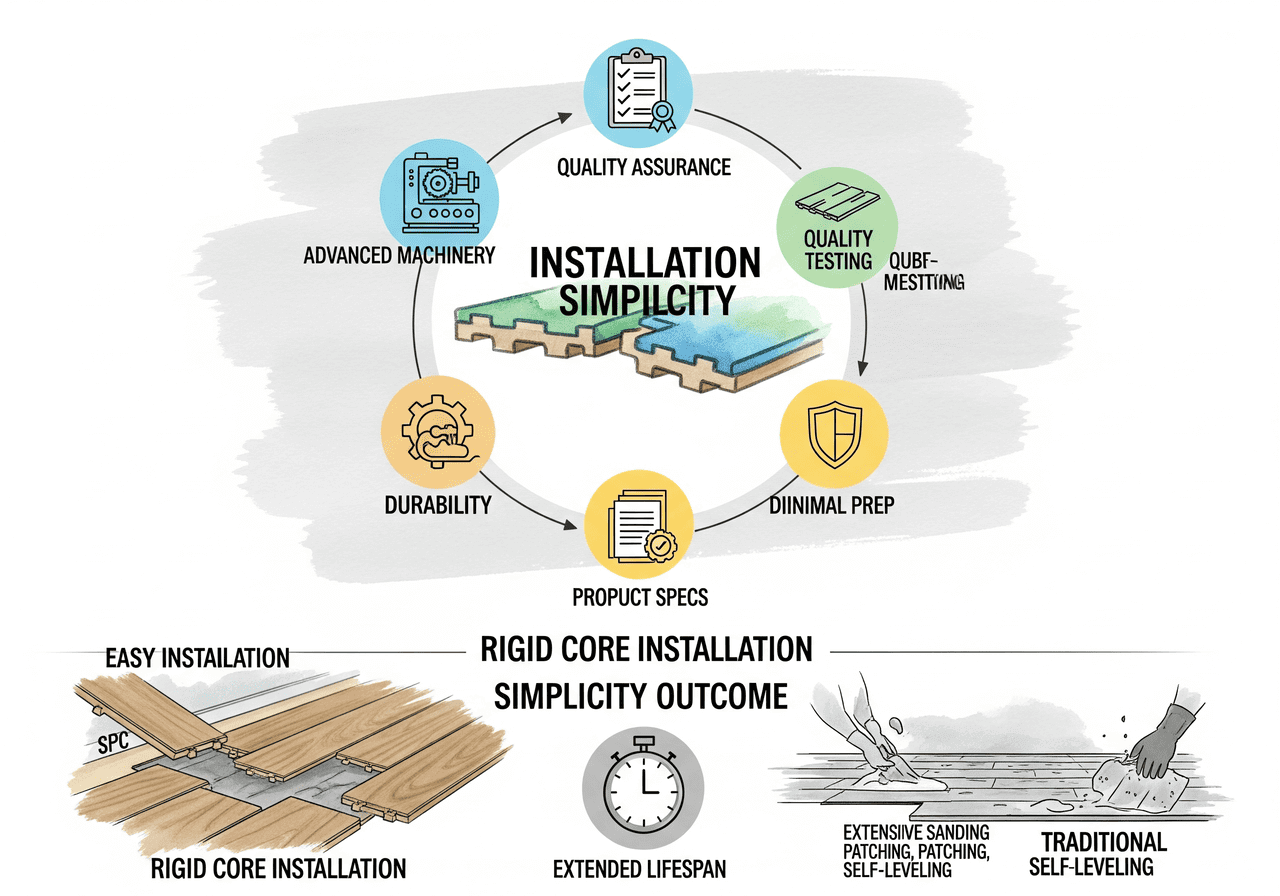

Rigid core flooring significantly simplifies installation due to its click-lock mechanism, which allows for floating installation without glue. Its rigid core also makes it highly forgiving of minor subfloor imperfections, reducing the need for extensive, costly preparation.

One of the biggest advantages I see for my wholesale clients is the simplified installation process of rigid core flooring. This is especially true for those distributing to installers. It directly helps with common issues like slow communication with sales reps and delayed shipments. These issues can affect selling seasons. With rigid core, much of the installation work is removed. My factory, with its advanced production lines for both LVT and SPC, ensures our click-lock systems are precise and easy to use.

This means less labor time on site. This is a huge benefit for both installers and end-users. Rigid core flooring uses a click-lock system. Planks or tiles snap together without glue, nails, or adhesives. This floating installation method is quick and easy. A room can often be finished in a single day. This makes it great for DIY projects or when time is short. We focus on providing top-quality, consistently engineered products that click into place perfectly, every time.

Also, rigid core flooring is much more forgiving with subfloor conditions. Older LVT or vinyl planks need a perfectly smooth, flat subfloor. Any small flaws would show through. This could cause bubbles, bumps, or an uneven surface. But, the stiffness of SPC and WPC planks means they can cover minor subfloor irregularities. They do not show through.

This greatly cuts down on the time and cost for subfloor preparation. This includes sanding, patching, or self-leveling. For buyers like Aiden, who care about quality but also want good prices, this means lower total project costs and faster project completion. This is a key factor when selling to a market that values efficiency. We also make sure our products need little to no time to get used to the environment. This further speeds up installation after delivery. This reliability helps our clients manage their inventory and sales better. It lowers the risk of missing selling seasons because of product delays.

Here are key advantages of rigid core flooring regarding installation:

-

Click-Lock Installation System1:

- Rigid core flooring uses a click-lock system. Planks snap together without glue, nails, or adhesives.

- This floating method is fast and easy. A room can often be finished in one day.

-

Minimal Subfloor Preparation2:

- As a floating floor, it can go over most existing hard surfaces. These include concrete, plywood, or ceramic tile.

- The subfloor just needs to be clean, level (within 3/16 inch per 10 feet), and dry. This cuts down on labor and time costs compared to older flooring that needs a lot of surface work.

-

Versatility Across Subfloor Types:

- Rigid core’s stability and waterproof nature let it go in challenging places. This includes basements or over radiant heating. It does not need special subfloor work.

- For concrete floors, a vapor barrier might be needed for moisture. But this is simple to add.

-

- Many rigid core products come with an attached underlayment, like cork or foam. This means you do not need to buy and install a separate layer.

- This feature makes it more comfortable, blocks sound, and makes installation faster.

-

Acclimation Requirements:

- Rigid core flooring needs minimal acclimation. This is usually 24-48 hours at 65°F-85°F. This makes installation easier than for hardwood or laminate, which need longer acclimation times.

Here is how rigid core compares in installation ease:

| Feature | Rigid Core Flooring (SPC/WPC) | Traditional LVT/LVP (Glue Down/Loose Lay) | Laminate Flooring |

|---|---|---|---|

| Installation Method | Click-lock floating installation | Glue down or loose lay | Click-lock floating installation |

| Glue Needed | No | Yes (for glue down) | No |

| Subfloor Prep | Minor imperfections acceptable | Requires very smooth, level subfloor | Requires very smooth, level subfloor |

| Acclimation Time | Minimal to none (usually) | Minimal (can vary) | Typically 24-48 hours |

| Tools Required | Basic hand tools, utility knife | Trowels, rollers, specialized cutters | Basic hand tools, saw (for cutting) |

| Water Resistance | 100% waterproof | Highly water resistant (if properly sealed) | Not waterproof, susceptible to water damage |

| DIY Friendliness | High | Moderate | High |

| Labor Cost Savings | Significant due to speed | Moderate to low | Moderate |

What new innovations and market trends are shaping the future of Rigid Core?

Are you wondering how to stay competitive in the rapidly evolving flooring market? Not keeping up with the latest innovations and trends in rigid core flooring can leave your business behind. Discover what is next to ensure your product offerings remain cutting-edge.

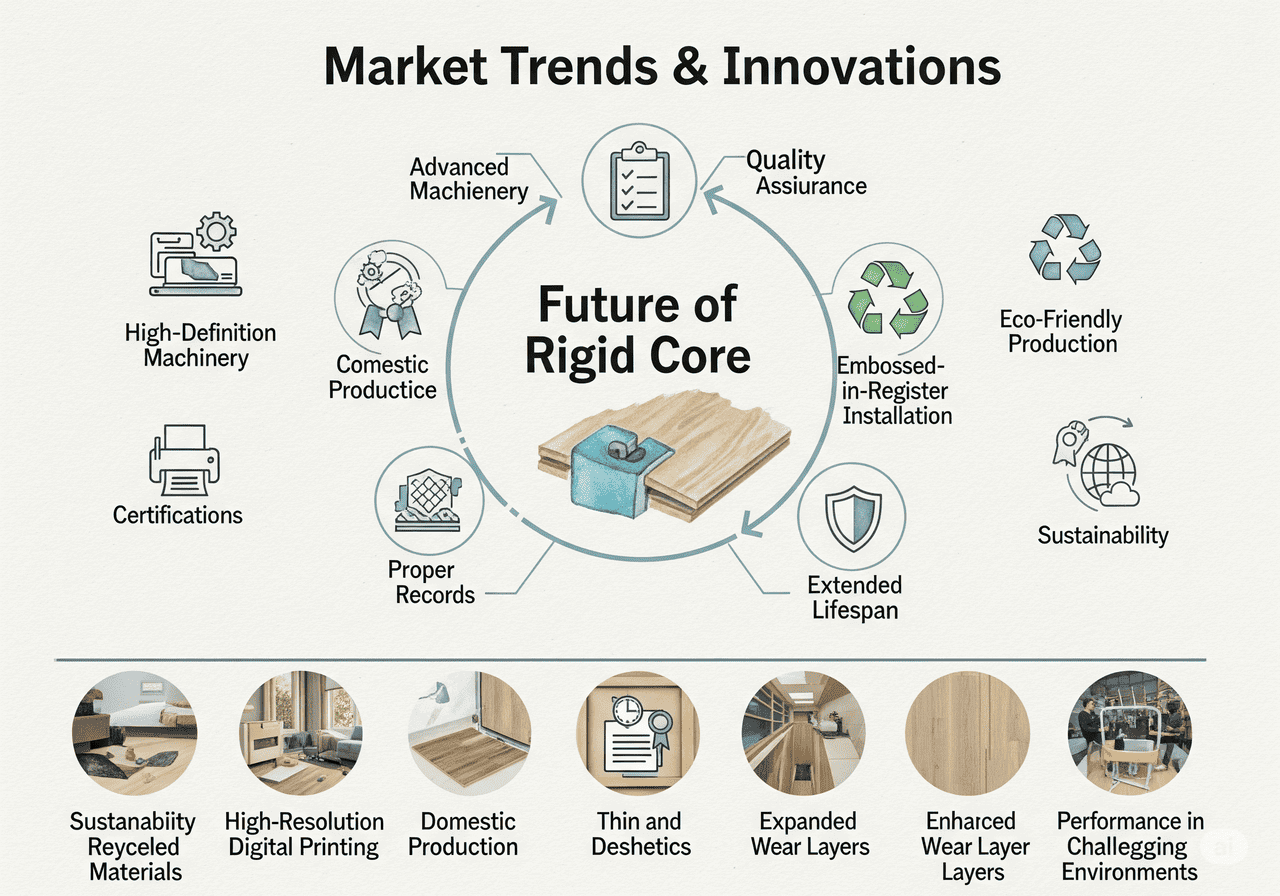

New innovations in rigid core flooring include advanced visual technologies like high-definition printing and embossed-in-register textures for hyper-realistic looks. Market trends also show a move towards integrated underlayment for comfort, wider/longer planks, and increased focus on sustainable production practices.

At CloudsFlooring, as a factory committed to top quality and rare styles, I am always watching for what is next in rigid core. My team and I go to exhibitions and follow industry news. This makes sure we offer the best and most relevant products. The future of rigid core is very exciting. It focuses a lot on how it looks and how it works.

Here are the key trends and innovations shaping rigid core flooring:

-

Sustainability and Eco-Friendly Materials1:

- There is growing demand for sustainable products. This pushes manufacturers to use recycled materials, like recycled stone or plastic, in rigid core flooring.

- Low-carbon production processes and certifications like FloorScore and GreenGuard are becoming normal. These appeal to buyers who care about the environment. My factory, as a responsible manufacturer in China, understands these certifications. We ensure our production meets environmental standards. We provide certifications when needed. This helps address buyer worries about fake documents.

-

Advanced Manufacturing Technologies2:

- Technologies like digital direct printing allow for high-resolution, realistic designs. This happens without a vinyl cap layer. This reduces material use and environmental impact.

- Enhanced core formulas for SPC and WPC improve durability, dent resistance, and stability. This ensures long-term performance.

-

Domestic Production Growth:

- Laws like the Uyghur Forced Labor Prevention Act (UFLPA) and other supply chain issues are causing a move towards domestic production. This is happening in North America and Europe. Companies are investing in new technology to make high-quality rigid core flooring locally. This reduces reliance on imports from China.

-

- Hybrid flooring is gaining popularity. It combines vinyl’s waterproofing with laminate’s stiffness. This makes it versatile and performs well in high-traffic or wet places.

- These products often have many layers. They have better wear layers and decorative layers for improved looks and durability.

-

Ultra-Thin, High-Durability Designs:

- Manufacturers are making thinner rigid core planks, as low as 6mm. These planks still keep very good durability. This cuts material costs and environmental impact without losing performance.

-

Expanded Design Options:

- High-definition printing and embossing technologies create very realistic wood, stone, and tile looks. They offer customizable finishes like matte or glossy. This also includes painted bevels and planks with many colors. This makes the finished floor look more real and custom. This focus on looks is key for buyers like Aiden, who might not be good at design but depend on their suppliers for appealing designs.

-

Performance in Challenging Environments:

- Rigid core flooring is more and more designed for tough conditions. This includes below-grade installations or busy commercial spaces. It has better edge sealing and joint integrity for waterproofing.

-

Smart and Functional Features:

- New innovations include antimicrobial coatings and built-in sensors for checking moisture levels. These add functionality for places like healthcare or commercial settings.

-

Ease of Maintenance and Installation:

- New products focus on surfaces that are easy to clean. They have scratch-resistant wear layers and simpler click-lock systems. This makes rigid core even more appealing to customers and installers.

-

Market Dynamics for Importers:

- Importers must deal with rules like the UFLPA. This requires meeting ethical sourcing standards.

- Growing demand for local production might change import plans. There are chances to work with manufacturers in North America or Europe.

- Importers should focus on finding products with certifications, green materials, and new designs. This helps meet many market needs. This commitment helps our wholesale clients, such as Jessie, confidently market their products as both high-quality and environmentally responsible.

Here is a summary of emerging trends and their benefits for importers:

| Trend | Description | Impact for Importers |

|---|---|---|

| Sustainability | Use of recycled materials (recycled stone/plastic), low-carbon production processes, and certifications like FloorScore and GreenGuard. | Meet growing consumer demand for eco-friendly products, fulfill regulatory requirements, enhance brand reputation. |

| Digital Printing | Advanced digital direct printing and embossing machinery for high-resolution, realistic designs (wood, stone, tile) without a vinyl cap layer, including Embossed-in-Register (EIR) textures. | Access to customizable, aesthetically superior flooring, reducing material use and environmental impact. |

| Domestic Production | Shift towards manufacturing in North America and Europe, driven by supply chain considerations and regulations like the UFLPA, reducing reliance on imports. | Potential for new supplier partnerships, increased focus on ethical sourcing, and navigating changing import strategies. |

| Hybrid Flooring | Development of flooring that combines vinyl’s waterproofing with laminate’s rigidity, offering versatile performance for various environments. | Opportunity to provide balanced, high-performance products suitable for mixed residential/commercial applications. |

| Thin, Durable Designs | Production of ultra-thin rigid core planks (as low as 6mm) that maintain exceptional durability, reducing material costs and environmental impact without sacrificing performance. | Offer cost-effective and environmentally friendly options while ensuring product robustness. |

| Expanded Designs | Creation of ultra-realistic wood, stone, and tile looks through high-definition printing and embossing, with customizable finishes like matte or glossy, including painted bevels and multi-tonal planks. | Appeal to diverse aesthetic preferences, enhance product appeal, and allow for higher margins on premium designs. |

| Smart Features | Emerging innovations such as antimicrobial coatings (for healthcare/commercial) and built-in sensors for checking moisture levels, enhancing functionality in specialized settings. | Tap into niche markets requiring advanced functional benefits, offering differentiation in product offerings. |

| Enhanced Wear Layers | Thicker, more durable wear layers designed for extreme traffic, increasing product lifespan and reducing complaints. | Provide products suitable for high-wear commercial projects, reinforcing quality perception and client trust. |

| Performance in Challenging Environments | Improved edge sealing and joint integrity for waterproofing, making rigid core suitable for below-grade installations or high-moisture commercial spaces. | Expand product application range to more demanding environments, addressing diverse client needs. |

Conclusion

Rigid core flooring’s evolution offers superior durability, easy installation, and stunning aesthetics. Staying updated on these advancements is key for importers to secure competitive advantages and meet market demands.

The above data is for reference only.

-

Explore this link to understand how sustainability is shaping the flooring industry and the benefits of eco-friendly materials. ↩ ↩ ↩

-

Discover how cutting-edge technologies are revolutionizing flooring production, enhancing design quality and sustainability. ↩ ↩

-

Learn about the advantages of hybrid flooring, which combines the best features of vinyl and laminate for versatile applications. ↩ ↩