Slips and falls are a big problem, causing injuries and huge costs. Is your vinyl flooring truly safe for everyone? Let’s make sure it is.

Ensuring anti-slip vinyl flooring compliance involves understanding global standards like those from ANSI, ISO, and various regional bodies. Manufacturers must integrate testing, quality control, and proper documentation into their processes to meet specific application requirements and mitigate risks effectively for LVT, SPC, LVP, and WPC products.

As a factory owner, I know how important it is to meet client expectations for high-quality flooring. But for vinyl flooring, safety goes beyond just aesthetics. It’s about protecting people and your business reputation. Let’s explore how we achieve that.

What are the core principles for global anti-slip standards?

Navigating global anti-slip standards for vinyl flooring can feel like a maze. Do you know the guiding principles behind these crucial safety measures? Let’s simplify this.

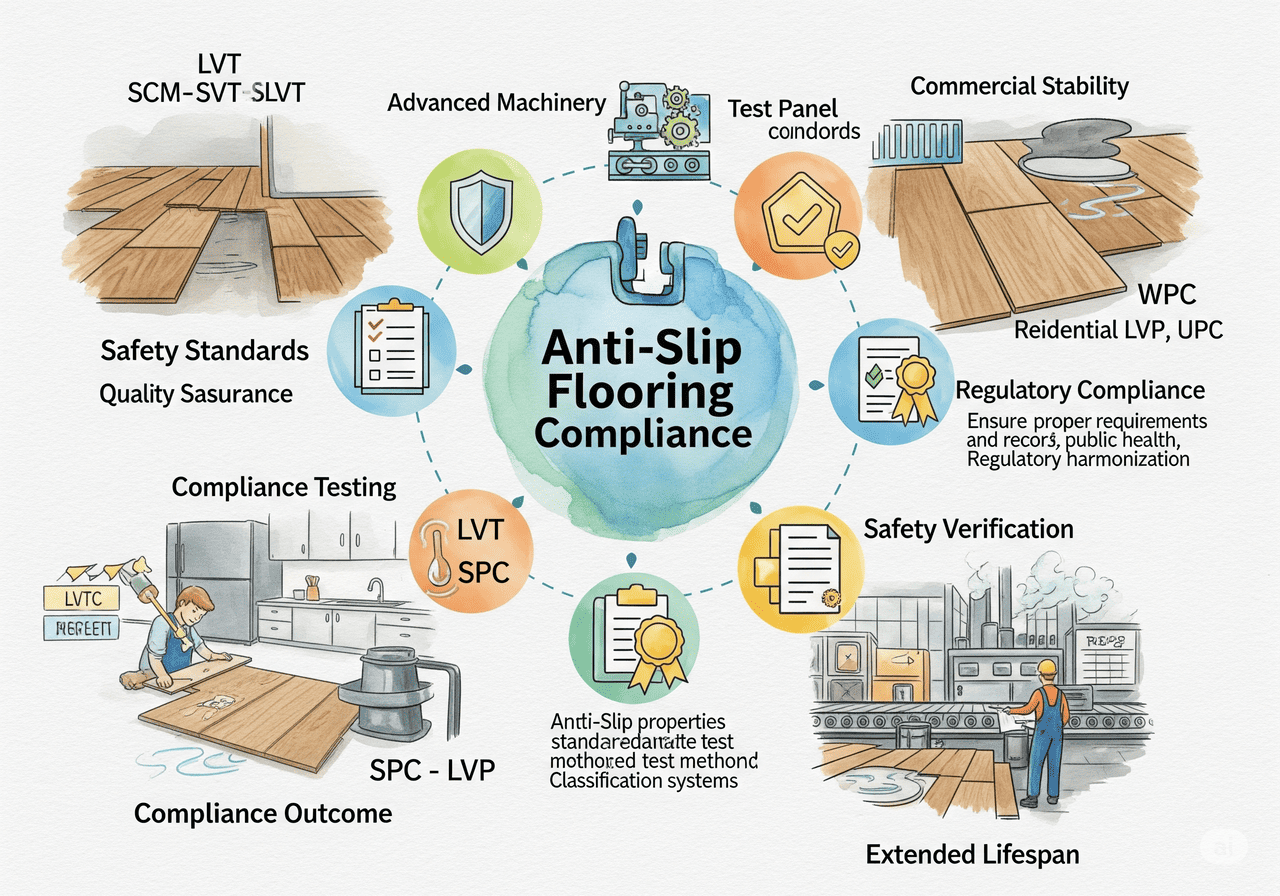

Anti-slip performance standards for vinyl flooring worldwide are built on core principles of safety, risk reduction, and public health. They aim to quantify surface friction under various conditions, ensuring these floors provide adequate grip for pedestrians and prevent slips, trips, and falls in diverse environments.

The development of anti-slip standards is not random. It follows key principles specifically relevant to vinyl flooring.

First, there is the principle of standardized test methods1. Regulatory bodies use consistent ways to measure slip resistance of vinyl flooring.

- For example, the pendulum test (like BS EN 16165:2021) or ramp test (like DIN 51130) are common.

- These tests evaluate the coefficient of friction (COF) or Pendulum Test Value (PTV) under specific conditions, often including wet environments, to ensure the vinyl floor’s performance.

- The goal is to ensure that results are reliable and comparable across different locations for vinyl flooring products.

Second, classification systems2 are vital. Standards categorize vinyl flooring based on how much slip resistance they offer.

- BS EN 16165:2021 uses R ratings (R9 to R13) from ramp tests. It also uses PTV classifications, like PTV ≥36 for safe vinyl flooring.

- DIN 51130, a German standard, assigned R values from R9 to R13 based on shod ramp tests with oil for various floor types, including those relevant to vinyl. These systems help buyers understand exactly what level of slip resistance a vinyl flooring product offers for specific uses.

Third, minimum requirements3 are set. These are specific thresholds that vinyl flooring must meet to be considered safe.

- In the U.S., ANSI B101.3 sets a minimum dynamic COF (DCOF) of >0.42 for level floors, which applies to vinyl surfaces.

- For Europe, BS EN 13893:2002 used to require a minimum COF of 0.3 for CE marking for resilient floor coverings, though this standard has since been updated. These requirements ensure a basic level of safety for consumers using vinyl flooring.

Fourth, application-specific standards are crucial. A hospital operating room needs much higher slip resistance than a dry office area, even for vinyl flooring. Standards are tailored to environments like wet areas or industrial zones.

- For instance, BS EN 16837:2018 for sports areas requires a specific linear friction value for sports flooring, including specialized vinyl.

- It is important to note that there is no direct correlation between different test methods, like pendulum versus ramp tests. This means specific tests are needed for each standard applicable to vinyl flooring.

Finally, regulatory harmonization aims to unify testing, but regional variations still exist. This means compliance with local rules for vinyl flooring is always needed. This understanding helps us at CloudsFlooring develop LVT and SPC products that truly meet global safety needs for our customers.

| Standard Body | Key Test Method (Example) | Principle Applied | Common Target (Example) |

|---|---|---|---|

| ANSI (US) | A326.3 (DCOF) | Standardized Test Methods | DCOF > 0.42 (wet) |

| UK (HSE) | Pendulum Test | Minimum Requirements | PTV > 36 (low slip risk) |

| DIN (Germany) | R-Value (Ramp Test) | Application Specificity | R9 to R13 |

| BS EN (Europe) | 16165 (Pendulum, Ramp) | Classification Systems | PTV ≥36, R-ratings |

How are compliance strategies integrated into product development and supply chains?

Waiting until the last minute for compliance checks costs time and money. Do you want to build anti-slip safety right into your vinyl flooring product from day one? Let’s see how.

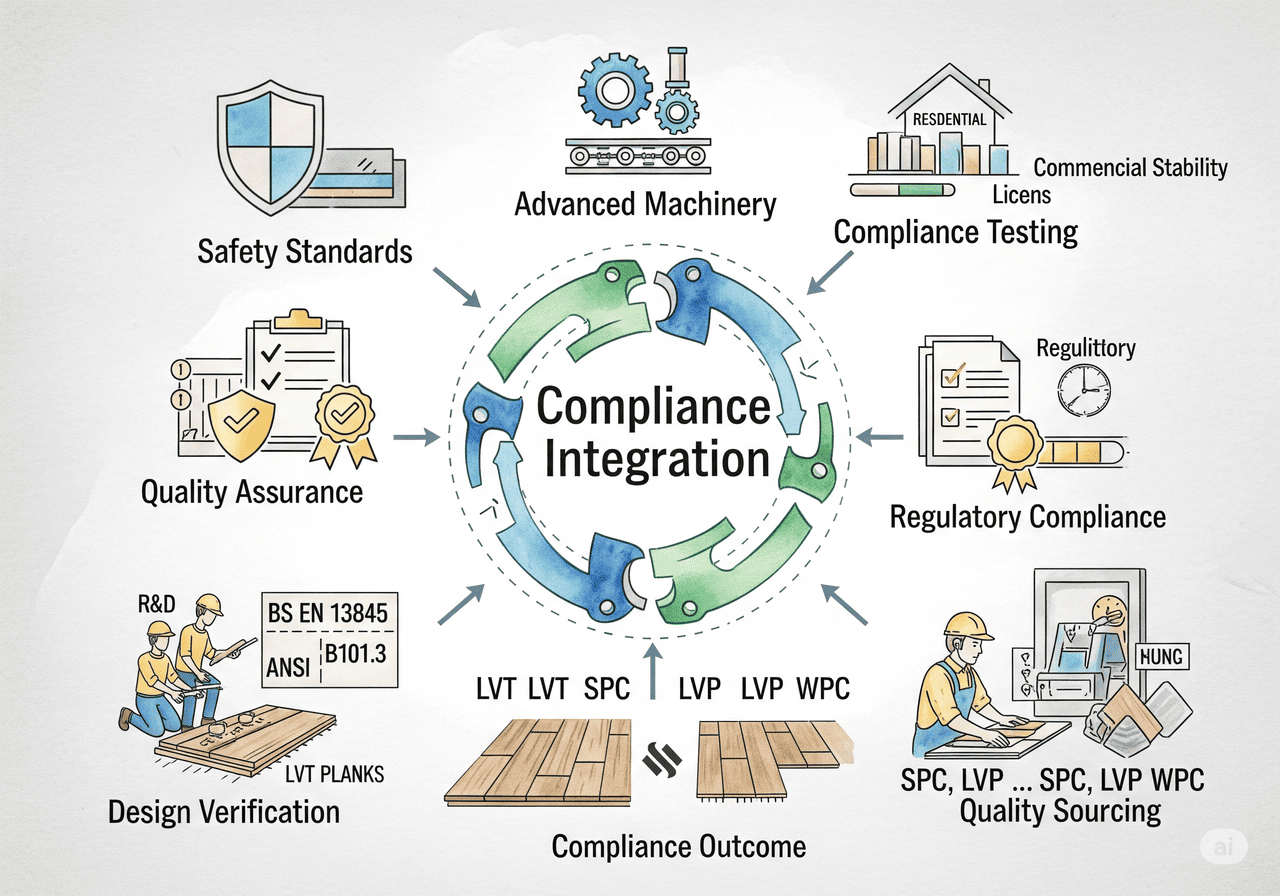

Vinyl flooring manufacturers can integrate compliance early by designing products with anti-slip properties as a core feature, not an afterthought. This involves selecting suitable raw materials, rigorous in-house testing during development, and implementing strict quality control checks throughout the entire production and supply chain process for LVT, SPC, LVP, and WPC.

At CloudsFlooring, we believe in proactive compliance for our vinyl flooring. It starts right at the product development stage.

1. Product Design and Development:

- When we design new LVT or SPC flooring, anti-slip performance is a key design parameter. We do not just think about colors or patterns.

- We incorporate anti-slip additives, like silica or aluminum oxide, directly into the wear layer or surface coating of our vinyl materials. This helps our LVT and SPC products meet standards like BS EN 13845 (for resilient floor coverings like PVC) or ANSI B101.3.

- Our R&D team works closely with production to test prototypes early. We use in-house DCOF testing1 equipment. We also conduct regular pendulum tests specifically on our vinyl flooring. This lets us make quick adjustments before mass production begins. We can adjust the texture of the wear layer or the formulation of the coating to enhance slip resistance.

2. Raw Material Sourcing:

- Our supply chain also plays a big part. We source raw materials for our vinyl flooring from trusted suppliers who meet our quality standards.

- We have clear specifications for all incoming raw materials, including the PVC base, decorative films, and wear layers. This helps ensure consistency.

- These layers directly affect the final vinyl product’s slip resistance.

3. Production Quality Control:

- During production, we implement strict quality control specifically for our vinyl flooring lines. We conduct regular batch testing and random spot checks on finished LVT and SPC products.

- If a vinyl flooring sample fails the anti-slip test, we investigate immediately. We identify the root cause and correct it.

- We also ensure our production lines for LVT and SPC are well-maintained.

4. Certification and Documentation:

- We obtain certifications like CE marking for Europe and ANSI certifications for the U.S. to validate the compliance of our vinyl flooring.

- This structured approach means that by the time the vinyl flooring leaves our factory, it has already met the required anti-slip standards.

- We also train our staff on vinyl flooring slip resistance standards and provide installation and maintenance guides to ensure our LVT and SPC products perform as intended, even after they leave our factory.

This consistency helps us deliver top-quality, compliant vinyl flooring every time, giving our customers, like Aiden in the UK and Lori in the US, peace of mind.

| Process Stage | Compliance Integration Action | Benefit for Customers |

|---|---|---|

| Product Design | Specify anti-slip as core feature | Vinyl products meet safety needs |

| R&D Prototyping | In-house DCOF/slip testing on samples | Faster development, better vinyl product |

| Raw Material Sourcing | Vet suppliers for quality; clear specs | Consistent, high-quality vinyl materials |

| Production QC | Batch testing, spot checks | Every vinyl product meets standards |

| Supply Chain Mgmt. | Partner with reliable logistics | On-time delivery, certified vinyl products |

How does anti-slip flooring enhance safety and reduce liability risks?

Meeting rules is one thing, but truly safe spaces save lives and protect businesses. Are you thinking about the bigger picture of safety and risk when it comes to vinyl flooring? Let’s dive in.

Anti-slip vinyl flooring goes beyond just meeting regulations; it actively enhances user safety by reducing slip-and-fall accidents, which are a leading cause of injuries. This directly mitigates liability risks for businesses, protecting them from costly lawsuits, insurance claims, and reputational damage in commercial and public environments.

For large company buyers like Aiden and Lori, liability is a major concern. Slips and falls are not just minor incidents. They can lead to severe injuries, including fractures, head trauma, and even long-term disability. Each incident can result in expensive medical bills, lost work time, and emotional distress for the injured person. For a business, this means potential lawsuits, increased insurance premiums, and a damaged public image.

High-quality anti-slip vinyl flooring is a strong defense against these risks.

1. Preventing Accidents:

- Anti-slip vinyl surfaces, often featuring grit (like fine silicon carbide embedded in the wear layer) or textured designs (like embossed patterns), prevent accidents in high-traffic or wet areas, such as commercial kitchens or hospital corridors.

- This significantly reduces the chance of someone slipping, creating a safer environment for everyone using LVT, SPC, WPC, or LVP.

2. Meeting Legal Requirements and Reducing Liability:

- By choosing vinyl flooring with certified anti-slip properties, businesses show they care about their customers and employees. This commitment to safety builds trust.

- Meeting standards like BS EN 16165 or OSHA guidelines demonstrates due diligence. This can reduce fines or legal action.

- By installing tested anti-slip vinyl flooring, businesses can defend against liability claims effectively. Proper documentation strengthens this defense.

3. Enhancing Visibility and Cost Savings:

- Sometimes, colored or high-contrast vinyl flooring, like yellow edges on stair nosings, can improve safety by reducing trip hazards. This also lowers liability.

- Fewer accidents also mean reduced medical and legal costs. This can offset the initial investment in anti-slip vinyl flooring. It is a smart business decision.

4. Comprehensive Safety Approach:

- Combining anti-slip vinyl flooring with good footwear and proper housekeeping, like quick spill cleanup, maximizes safety. This also minimizes liability.

- As a manufacturer, I understand this deeply. We provide vinyl floors that not only look good but also act as a crucial safety barrier. This means our LVT and SPC flooring solutions help our clients not just meet codes but also secure their operations and reputation. This is especially important in places like North America and the UK, where liability laws are strict. We aim to be a partner in our clients’ risk mitigation strategies.

| Risk Area | Impact of Poor Anti-Slip Vinyl Flooring | Benefit of Anti-Slip Vinyl Flooring |

|---|---|---|

| User Safety | Increased slip-and-fall injuries | Reduced accidents, improved well-being |

| Legal Liability | Costly lawsuits, penalties | Protection from claims, legal defense |

| Insurance Premiums | Higher rates due to claims | Lower premiums, better risk profile |

| Business Reputation | Negative public perception | Enhanced brand image, customer trust |

| Operational Costs | Lost productivity from injuries | Minimized disruptions, efficient ops |

How do regional anti-slip standards impact exporters’ liability risks?

Exporting vinyl flooring means facing different rules in every country. Are you prepared for varying anti-slip standards1 and their legal consequences for LVT, SPC, LVP, and WPC? Let’s navigate this.

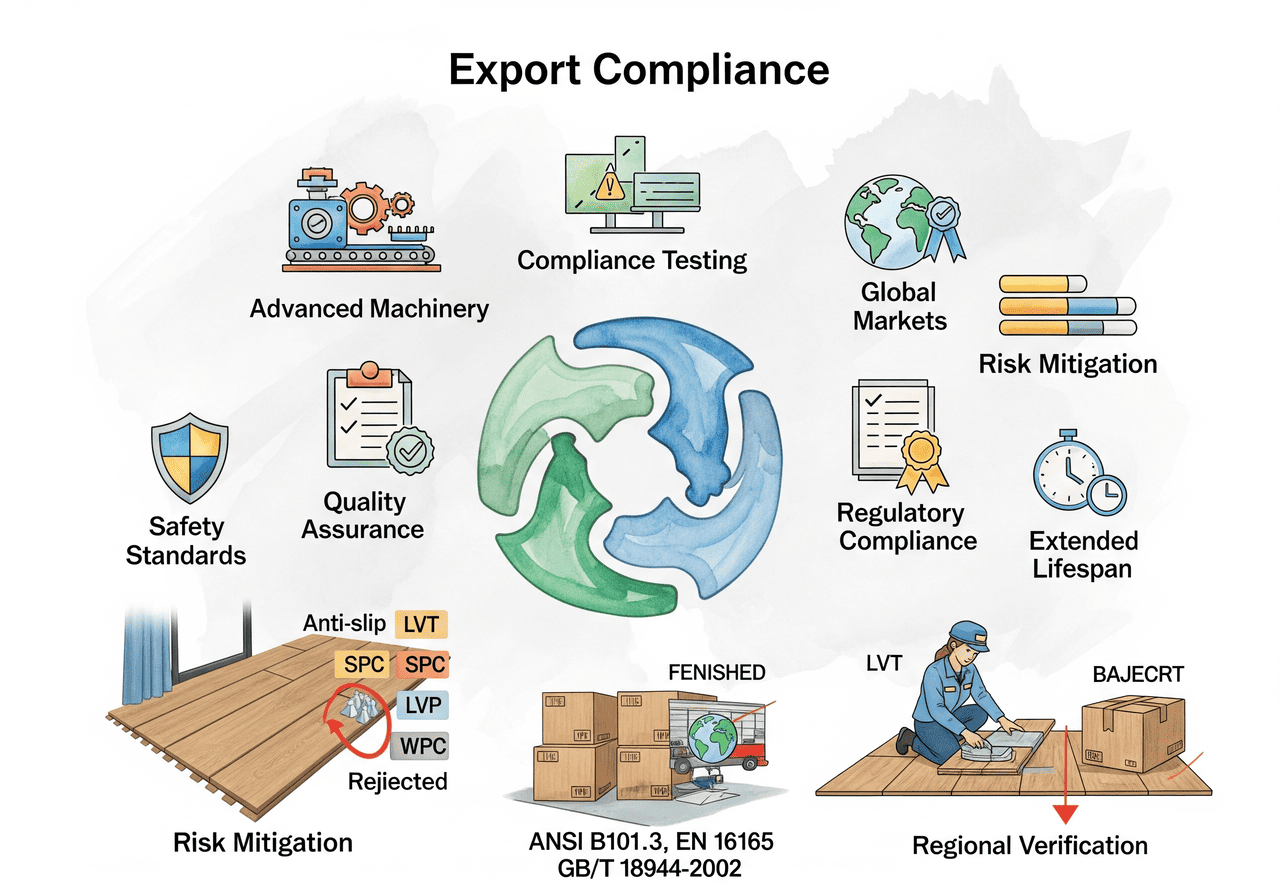

Regional anti-slip standards significantly impact exporters of vinyl flooring, requiring them to adapt products to meet diverse regulations in each market.

Failure to comply can lead to product rejection, costly recalls, and severe liability issues, including lawsuits and financial penalties, affecting market access and business reputation in key export regions.

As an exporter of LVT and SPC flooring to North America, the UK, and the Middle East, I deal with regional standards all the time. It is a big challenge for vinyl flooring.

1. Diverse Standards Across Regions:

- North America: The U.S. often refers to OSHA recommendations for COF ≥0.5, while ANSI B101.3 requires a DCOF >0.42 for level floors; these apply to all flooring types including vinyl.

- Europe: Standards like EN 16165:2021 and BS EN 13845:2017 set specific ramp and pendulum test requirements for resilient floor coverings like PVC (the base for LVT/SPC).

- Asia-Pacific: Countries like China might use their own voluntary standards, such as GB/T 18944-2002 for non-skid coatings, which can include vinyl surfaces. These differences mean we cannot just make one type of vinyl flooring and sell it everywhere. We must understand each market’s specific anti-slip testing methods and acceptable values for LVT, SPC, and similar products.

2. Compliance Risks for Exporters:

- Failing to meet these regional standards has serious consequences. First, customs might reject vinyl flooring shipments. This leads to huge delays and financial losses.

- Second, if non-compliant vinyl flooring is installed and causes an accident, the exporter can face legal action. This liability extends to the manufacturer.

3. Liability Issues and Brand Reputation:

- This is where our clients, like Aiden and Lori, face their own risks if they source non-compliant vinyl flooring products. They could lose their business reputation.

- They could also face expensive lawsuits and recalls of their vinyl flooring products. This is a major pain point for them.

4. Adaptation and Certification Needs:

- To counter this, we at CloudsFlooring work hard to know these rules. We ensure our LVT and SPC products are tested to the relevant standards for each target market.

- We may need to modify our vinyl flooring products, for example, by adding specific anti-slip additives or adjusting surface textures, to meet these regional requirements.

- We provide proper documentation and mandatory certifications like CE marking for Europe or ANSI for the U.S. This helps our clients avoid these common pitfalls and maintain their market position for vinyl flooring. It is about being a reliable partner. We help them navigate the complex global landscape of regulations and potential liability.

| Region | Key Anti-Slip Standard/Test (Vinyl Flooring Relevant) | Potential Liability Impact |

|---|---|---|

| North America (US) | ANSI A326.3 (DCOF), OSHA recommendations | High litigation risk; product recalls |

| United Kingdom | HSE Pendulum Test (PTV), BS 4592 | Strict safety laws; fines; claims |

| European Union | EN 16165, EN 13845 (for resilient coverings) | Market access issues; reputational damage |

| Asia-Pacific | GB/T 18944-2002 (China), local codes | Import restrictions; brand impact |

| Middle East | Often ISO-based or local codes | Import restrictions; brand impact |

What are the mandated anti-slip requirements for critical areas?

Some places cannot afford even a single slip. Do you know the super strict anti-slip requirements for LVT, SPC, LVP, and WPC in high-risk zones? Let’s look at this critical safety need.

Critical environments like hospitals, commercial kitchens, and public entryways mandate very high anti-slip performance1 levels for vinyl flooring due to increased slip risks.

Building codes typically require specific DCOF values2, Pendulum Test Values, or R-ratings, often above general use standards, to ensure maximum safety and minimize severe injury potential in these high-traffic or wet areas.

For critical environments, the stakes for vinyl flooring are much higher. Think about a hospital operating room, a busy restaurant kitchen, or a pool deck.

In these areas, the presence of liquids, oils, or heavy foot traffic dramatically increases the risk of slips. Therefore, building codes and specific industry regulations demand higher anti-slip performance from flooring, including LVT and SPC.

Here are some examples of what is typically mandated for vinyl flooring:

-

European Standards for Resilient Flooring:

- BS EN 16165:20213 specifies ramp, pendulum, and tribometer tests for various floor types. It requires a PTV ≥36 for safe flooring in high-risk areas, which applies to high-performance vinyl.

- BS EN 13845:2017, specifically for resilient floor coverings like PVC (the base for LVT/SPC), requires ramp test angles of ≥20° for shod areas and ≥15° for barefoot areas. It also requires a PTV ≥36 for these vinyl products.

- BS 4592-0:2006+A1:2012, for industrial flooring, categorizes surfaces as unsuitable (<0.4 COF), slip resistant (0.4-<0.6), or enhanced (>0.6), applicable to robust vinyl options.

- BS EN 16837:2018, for sports areas, requires a linear friction value of 80-115 for CE compliance, which includes specialized vinyl sports flooring.

-

United States Standards for Floor Surfaces:

- ANSI B101.3 mandates a DCOF >0.42 for level floors, which applies broadly to vinyl flooring. For high-risk areas, a significantly higher DCOF might be needed or recommended by specific bodies.

- The Americans with Disabilities Act (ADA) emphasizes slip-resistant surfaces for accessibility. While it does not specify a COF value, it focuses on ensuring safe passage for all users on various surfaces, including vinyl.

-

Building Codes:

- The International Building Code (IBC) stresses slip resistance for wet or lubricated surfaces. It requires specifiers to justify their flooring choices for places like restrooms or commercial kitchens, which frequently use vinyl flooring.

Our LVT and SPC flooring can be manufactured with specialized surface textures and coatings to meet these stringent requirements. We often produce custom orders for clients who need specific anti-slip ratings for projects like healthcare facilities or schools.

This ensures our vinyl flooring products are safe for specific high-risk applications. We understand that these strict requirements protect both the end-users and our clients from potential harm and liability.

| Environment/Area | Typical Slip Risk Factors | Example Anti-Slip Requirement (General) | Our Vinyl Product Solution (Example) |

|---|---|---|---|

| Commercial Kitchens | Grease, water, food spills | High DCOF (>0.50), R12-R13, PTV >40 | Textured SPC, enhanced wear layer |

| Hospitals/Healthcare | Liquids, foot traffic, wheelchairs | DCOF >0.42 (wet), PTV >36 | Smooth LVT with consistent DCOF |

| Public Entrances | Rain, snow, high traffic | DCOF >0.50 (wet), PTV >36 | Embossed LVT, special top coat |

| Industrial Zones | Oils, chemicals, heavy loads | R11-R13, PTV >40 | Durable SPC with aggressive texture |

| Bathrooms/Pool Areas | Constant wetness | DCOF >0.50, PTV >36 | Textured LVT/SPC for wet areas |

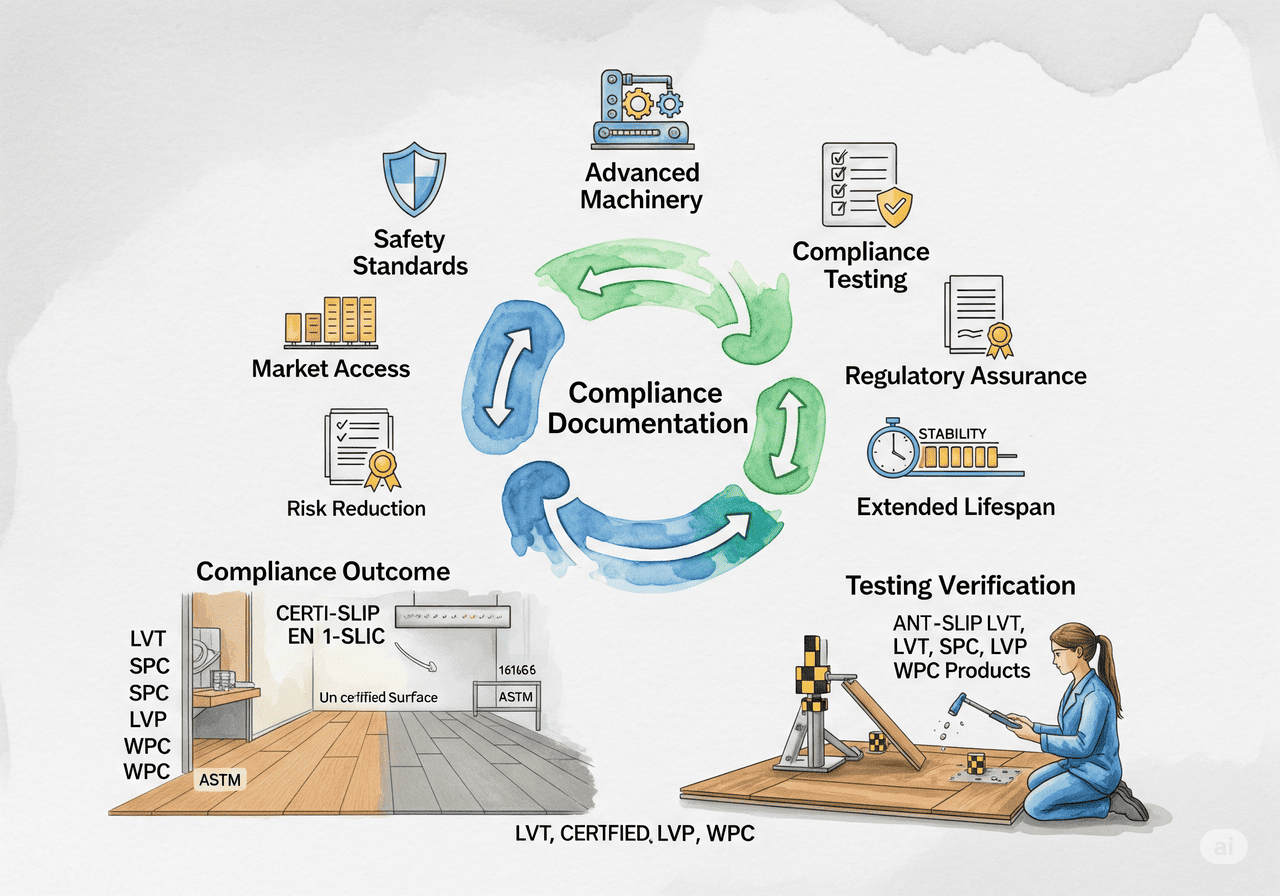

How is anti-slip compliance documented and certified?

Proof is everything when it comes to compliance. Do you have the right papers to show your vinyl flooring meets all safety rules? Let’s ensure your documentation is solid.

Manufacturers and exporters prove anti-slip compliance for vinyl flooring by providing comprehensive documentation. This includes official test reports from accredited third-party labs, certificates of conformity, material safety data sheets, and detailed product specifications.

This paperwork demonstrates adherence to regional and international anti-slip standards for transparent market access and liability protection of LVT, SPC, LVP, and WPC products.

For our clients, especially large buyers like Aiden and Lori, reliable documentation for vinyl flooring is crucial. It’s not enough to say our vinyl flooring is anti-slip; we must prove it. At CloudsFlooring, we provide a full suite of documents.

1. Test Reports:

- We provide test reports from accredited laboratories. These reports detail the slip resistance test results for our vinyl flooring, such as pendulum test PTV values (e.g., PTV ≥36) or ramp test angles (e.g., ≥20° for shod areas).

- These labs conduct standardized tests under wet and dry conditions and issue official, globally recognized reports specific to flooring materials like LVT and SPC. This clear data gives our clients confidence and proves our claims.

2. Certifications:

- We secure certifications like CE marking for Europe or ANSI B101.3 for the U.S. These confirm our vinyl flooring products meet specific regional standards.

- These certifications are often mandatory for market access.

3. Technical Data Sheets:

- We offer technical data sheets1 that provide detailed information about the material composition, specific COF or PTV values, and maintenance requirements for our LVT and SPC flooring.

4. Declarations of Conformity:

- We issue Declarations of Conformity. These are formal statements confirming our vinyl flooring products meet relevant standards like EN 16165 or OSHA guidelines.

5. Installation and Maintenance Guidelines:

- We also provide clear installation instructions. These guidelines are essential to ensure the vinyl flooring maintains its slip resistance after it is installed, especially in high-risk areas.

- We offer maintenance guidelines for cleaning and upkeep, as proper care preserves the anti-slip properties of the vinyl flooring over time.

We conduct our own internal testing and verify compliance with standards like EN 13845 or ASTM for our vinyl flooring. We maintain detailed records of test results, certifications, and material specifications for any audits or customer requests. We also collaborate closely with our raw material suppliers to ensure their materials meet our slip resistance requirements for vinyl production.

We regularly update our documentation to reflect any changes in standards or product formulations. This comprehensive package addresses client pain points like needing clear quality control and avoiding fake certificates. We pride ourselves on transparent communication and authentic paperwork. This means our clients can trust the quality and compliance of our LVT and SPC flooring, making their import and distribution efforts smoother and more reliable.

| Document Type | Purpose/Information Provided | Importance for Exporters/Buyers |

|---|---|---|

| Third-Party Test Reports | Official test results (DCOF, PTV, R-value) from accredited labs for vinyl flooring | Verifies anti-slip performance; legal proof |

| Certificates (e.g., CE, ANSI) | Confirms vinyl product meets regional/international standards | Required for market access; customs |

| Technical Data Sheets | Details on material composition, COF/PTV values, maintenance for vinyl products | Aids in product selection; ensures fit for purpose |

| Declarations of Conformity | Formal statement vinyl product meets relevant standards | Demonstrates adherence; legal compliance |

| Installation Instructions | Guidelines for proper installation to maintain slip resistance for vinyl flooring | Ensures performance post-installation |

| Maintenance Guidelines | Instructions for upkeep to preserve anti-slip properties of vinyl flooring | Long-term performance; liability reduction |

Conclusion

Ensuring anti-slip compliance for vinyl flooring is vital for safety, risk management, and market access. At CloudsFlooring, we proactively integrate these standards, providing top-quality, well-documented LVT and SPC solutions for global markets.

The above data is for reference only.

-

Discover how technical data sheets provide crucial information for vinyl flooring compliance and help in product selection. ↩ ↩ ↩ ↩ ↩

-

This link will provide insights into the specific DCOF values required for different environments, helping you choose the right flooring for safety. ↩ ↩

-

Learn about the standards set by BS EN 16165:2021 for resilient flooring, crucial for ensuring safety in high-risk areas. ↩ ↩