Struggling to find trustworthy SPC suppliers? Poor choices lead to costly delays and defects. Here’s how I learned to spot the truly reliable ones for my business.

Identify reliable SPC manufacturers by checking certifications like ISO 9001 and FloorScore, verifying their production quality through samples and reports, assessing communication responsiveness, considering factory audits, and confirming if they are a real factory or a trading company. These checks build trust and ensure quality.

Finding the right partner is crucial for your business success. It took me time to develop a system, but it saves headaches later. Let’s break down exactly what you need to look for, step by step, so you can source with confidence, just like I do now for CloudsFlooring.

What certifications should a reliable SPC manufacturer have?

Confused about which certifications really matter for SPC flooring? Missing or fake ones can mean unsafe products and serious import problems down the line for your customers. Focus on these essential documents first.

A reliable SPC manufacturer should have quality management certs like ISO 9001. Look for product safety and environmental certs like FloorScore for indoor air quality and CE marking for European markets. These show commitment to verifiable standards.

Certifications aren’t just pieces of paper; they are proof that a manufacturer meets specific international standards. This is important for several reasons. First, it assures a basic level of quality management and product safety. Second, certain certifications are often required for market access, like CE marking in Europe or FloorScore in North America, especially for projects concerned with air quality. Without them, your products might be rejected by customs or specific clients. I learned early on that chasing the lowest price often meant dealing with suppliers who cut corners on compliance – a mistake I don’t make anymore.

Key Certifications Explained

Here are some of the main certifications I always look for when vetting a potential SPC flooring supplier:

- ISO 90011: This shows the factory has a Quality Management System in place. It means they have documented processes for ensuring consistent quality, handling issues, and aiming for customer satisfaction. It’s a fundamental check.

- ISO 14001: This relates to Environmental Management Systems. It indicates the factory tries to minimize its environmental impact, which is increasingly important to buyers and end-users.

- FloorScore®2: This is crucial, especially for North American markets. It certifies that the flooring meets strict indoor air quality (IAQ) standards, ensuring low volatile organic compound (VOC) emissions. This is vital for health and safety.

- CE Marking3: If you sell into the European Economic Area, this is mandatory. It declares that the product meets EU safety, health, and environmental protection requirements.

How to Verify Certifications

Never just accept a scanned copy or a mention on a website. I always ask for the certificate number and issuing body. Then, I try to verify it directly on the certifying organization’s website or by contacting them. Also, check the validity dates! I’ve encountered suppliers using expired or even fake certificates, which is a major red flag. At CloudsFlooring, we make sure all our certifications are up-to-date and easily verifiable for our clients. It builds trust from the start.

How can you verify a manufacturer’s production quality?

Concerned about receiving inconsistent SPC flooring quality batch after batch? Bad batches can damage your brand’s reputation and lead to costly claims. Use these methods I rely on to verify production standards effectively.

Verify production quality by requesting detailed product specifications and samples for testing. Ask about their internal quality control (QC) procedures, raw material sourcing policies, and any available third-party testing reports. Consistency across different batches is absolutely key.

Verifying quality isn’t just about checking one sample; it’s about understanding the manufacturer’s entire process and consistency. A good-looking sample doesn’t guarantee that your bulk order will be the same. You need to dig deeper into how they ensure quality from start to finish. This protects your investment and your customers. I always explain to my clients, like Mark in Canada, that our focus at CloudsFlooring is on repeatable, high-quality output, which starts long before the production line.

The Role of Raw Materials

The final quality of SPC flooring heavily depends on the raw materials used. Key components include:

- PVC Resin: Is it virgin or recycled? Virgin PVC generally offers better stability and performance. Ask the manufacturer for clarity on this.

- Limestone Powder: The quality and fineness of the limestone affect the core’s density and rigidity.

- Stabilizers and Additives: These impact dimensional stability, UV resistance, and overall durability. Ask about the type of stabilizer used (e.g., calcium-zinc is more eco-friendly than lead-based).

- Wear Layer: This clear top layer determines scratch and stain resistance. Ask about its thickness (e.g., 0.3mm, 0.5mm, 0.7mm) and the quality of the UV coating.

A reliable manufacturer should be transparent about their raw material sources and specifications.

Understanding the QC Process

Ask potential suppliers detailed questions about their Quality Control (QC) process1. A robust QC system involves checks at multiple stages:

- Incoming Raw Material Inspection: Do they test raw materials before they enter production?

- In-Process Quality Checks: Are there checks during extrusion, lamination, and cutting? What parameters do they monitor (e.g., thickness, density, temperature)?

- Final Product Testing: What tests are performed on the finished planks? This should include dimensional stability, locking strength, wear resistance, and visual defect checks.

Ask to see their QC checklist or standard operating procedures (SOPs). Seeing documented processes is more convincing than verbal assurances.

Using Samples and Reports

Samples are essential, but use them wisely. Request samples from current production batches if possible, not just ‘golden samples’. Test them yourself or send them to a lab for basic checks (e.g., measure dimensions, check locking system integrity, try scratching the surface). Also, request recent internal QC reports or third-party test reports for the specific product you’re interested in. At CloudsFlooring, we routinely test our batches and can provide these reports to give buyers confidence.

Why is communication so important when choosing a supplier?

Tired of supplier communication problems causing confusion and stress? Misunderstandings or slow responses can lead to incorrect orders, missed deadlines, and frustrating delays. Good communication1 is non-negotiable for smooth B2B operations.

Communication is vital because it ensures your detailed specifications are understood correctly. Good communication prevents costly errors, allows for quick problem-solving when issues arise, and builds a trusting, reliable relationship, which is essential for long-term B2B partnerships.

From my experience dealing with buyers worldwide, clear and timely communication is often just as important as the product quality itself. Think about it – every step, from initial inquiry to customization, production updates, shipping arrangements, and after-sales support, relies heavily on communication. If the communication breaks down, the whole process can falter, leading to significant business disruptions. I remember early in my career, a simple misunderstanding about color tones due to poor communication led to a whole container needing rework – a costly lesson!

What Makes Communication ‘Good’?

Good communication with a supplier isn’t just about language fluency, though that helps. It involves several key elements:

- Responsiveness2: How quickly do they reply to emails or messages? A reasonable timeframe (e.g., within 24-48 hours) shows they value your business. Consistent delays are a red flag.

- Clarity: Do they understand your technical requirements? Can they explain their capabilities and processes clearly? Using simple, direct language avoids confusion.

- Proactiveness: Do they provide updates without you constantly chasing them? A good partner will inform you about production milestones or potential delays proactively.

- Accessibility: Can you reach the right person when needed? Is there a dedicated contact person for your account? Are they available for calls if needed?

Impact on Business Operations

Poor communication directly impacts your bottom line and operations. Consider Mark Chen’s pain points: delays missing selling seasons, inefficient back-and-forth. These often stem from communication issues. Specific impacts include:

- Order Accuracy3: Misinterpreting specifications leads to wrong products.

- Lead Times: Slow responses delay decision-making and production starts.

- Problem Solving: Issues inevitably arise (e.g., shipping delays, minor defects). Quick, clear communication is crucial to resolve them efficiently. Slow or unclear communication turns small problems into big ones.

- Customization: For custom orders (like specific colors, logos, or packaging), precise communication is absolutely essential.

Assessing Communication Early

You can start assessing communication quality right from your first interaction. Send a detailed inquiry email. How quickly and thoroughly do they respond? Do they answer all your questions, or just give generic replies? Request a video call to discuss requirements – this helps gauge their professionalism and language skills. At CloudsFlooring, we train our sales team to be responsive and clear, understanding that this builds the foundation for a strong partnership.

How do factory audits help ensure reliability?

Need solid proof a manufacturer can actually deliver on their promises and quality claims? Relying on website pictures and salesperson talk alone is risky business. Factory audits1 provide crucial, objective insights into their real capabilities.

Factory audits help ensure reliability by verifying a manufacturer’s claimed production capacity, quality control systems, working conditions, and compliance with international standards. They provide firsthand, objective proof of their operational capabilities and legitimacy.

An audit is like looking under the hood. It moves beyond promises and marketing materials to see the reality of the factory’s operations. For buyers making large volume commitments, especially those like Mark who need consistent quality and reliable supply chains, an audit provides invaluable peace of mind. It helps confirm that the factory isn’t just a small workshop pretending to be a large producer, and that they have the systems in place to handle your orders effectively and ethically. It’s an investment that can prevent much larger problems later.

What Does an Audit Cover?

A comprehensive factory audit typically examines several key areas:

- Production Capacity: Verifying the number of production lines, machinery condition, output volume, and workforce size to ensure they can handle your order volume and meet deadlines. We have 3 LVT lines and 2 SPC lines at CloudsFlooring, something easily verified during an audit.

- Quality Management System (QMS)2: Assessing their QC procedures, documentation, testing equipment calibration, handling of non-conforming products, and traceability. This confirms if their quality talk matches reality.

- Facilities and Equipment: Checking the condition and maintenance of the factory floor, warehouses, and machinery.

- Social Compliance3: Increasingly important, this checks working hours, wages, health and safety conditions, and adherence to labor laws. This protects your brand from association with unethical practices.

- Environmental Compliance: Assessing waste management, pollution control, and adherence to environmental regulations.

Types of Audits

There are different ways to conduct an audit:

- First-Party Audit (Self-Assessment): The factory assesses itself. Least reliable.

- Second-Party Audit (Customer Audit): You or your representative visits the factory. This gives you direct insight but requires time and travel.

- Third-Party Audit: An independent, accredited auditing company (like SGS, Intertek, TUV) performs the audit. This is often the most objective and credible option, providing a detailed, unbiased report.

- Virtual Audit: A remote option using video calls and document sharing, which gained popularity recently. It’s less thorough than an in-person visit but better than no audit at all.

Interpreting Audit Results

The audit report provides detailed findings and may highlight areas of concern (non-conformities). Don’t just look for a pass/fail. Understand the specific findings. Are they minor issues that can be easily fixed, or major systemic problems? Discuss the findings with the manufacturer. A reliable partner will be open about the results and present a corrective action plan if needed. We welcome audits at CloudsFlooring as a way to demonstrate our capabilities and commitment transparently.

What’s the difference between a trading company and a real factory?

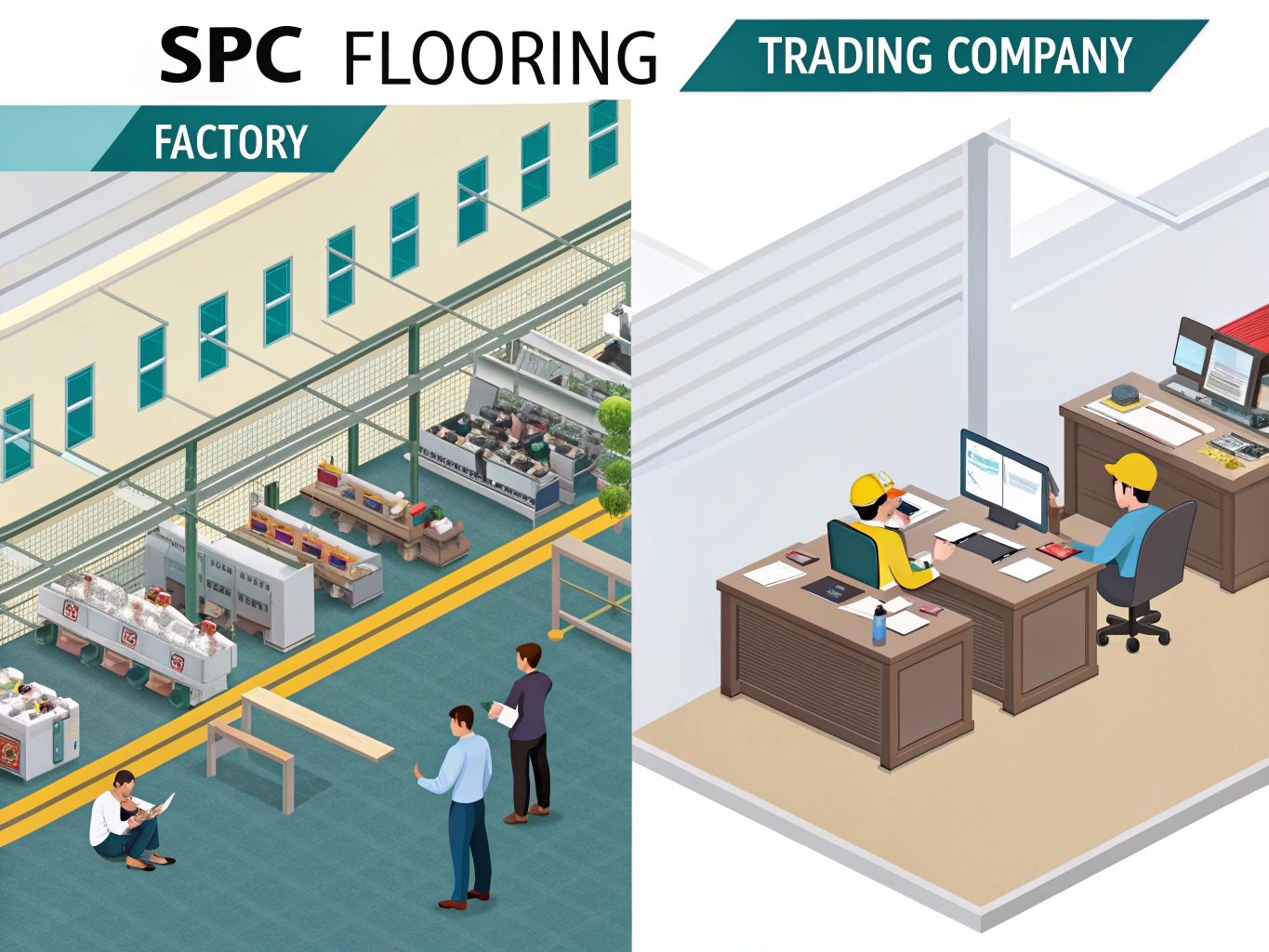

Confused about whether you’re dealing directly with the people making your SPC flooring or with a middleman? Working through intermediaries, known as trading companies, can sometimes add costs and communication layers you might want to avoid. Understand the difference clearly.

A real factory, like us at CloudsFlooring, manufactures SPC flooring in-house using its own production lines and workforce. A trading company typically buys finished products from one or more factories and then resells them, often under their own brand. The key difference lies in control over production, directness of communication, and often, price.

Knowing who you are dealing with is fundamental in sourcing. While trading companies can sometimes offer convenience, especially if you need a wide variety of products consolidated, dealing directly with a factory often provides significant advantages, particularly for buyers focused on SPC flooring like many of my clients. Direct interaction usually means better technical understanding, more control over customization, clearer quality oversight, and potentially better pricing by cutting out the middleman’s margin.

Defining Factory and Trader

- Factory (Manufacturer): Owns or operates production facilities. Has engineers, production workers, and QC staff involved in making the product. Their core business is manufacturing. Examples like CloudsFlooring have specific production lines (LVT, SPC) and factory space (20,000 sq meters for us).

- Trading Company (Intermediary/Distributor): Does not own production facilities for the products they sell (or maybe only for some). They act as a bridge between buyers and factories. They often have strong sales teams and may offer services like sourcing, logistics, and financing.

Pros and Cons

| Feature | Factory Direct | Trading Company |

|---|---|---|

| Price | Often lower (no middleman) | Can be higher (includes margin) |

| Communication | Direct with technical staff | Through salesperson (can be filter) |

| Customization | High control & flexibility | Limited by factory relationship |

| Quality Control | Direct insight into process | Relies on factory’s QC / own checks |

| Product Range | Focused (e.g., SPC/LVT) | Often very broad |

| Expertise | Deep technical product knowledge | Broad market knowledge |

| Factory Visit | Easy and encouraged | Can be difficult or deflected |

| Problem Solving | Faster, direct resolution | Can involve extra steps/delays |

How to Identify Them

It’s not always obvious, as some traders present themselves convincingly. Here’s how I check:

- Business License: Ask for it. Check the registered business scope. Does it say "manufacturing" or primarily "trading," "import/export," "wholesale"?

- Website & Product Range: Does the website show detailed factory pictures (not just stock photos)? Is the product range highly focused (like ours on LVT/SPC) or extremely diverse (e.g., flooring, furniture, electronics)? A very wide range often indicates a trader.

- Technical Depth: Ask detailed technical questions about the production process. Factory staff can usually answer deeply; traders might be vague or need to "check with the factory."

- Factory Visit Invitation: A real factory will readily invite you to visit their production site. Traders might be hesitant, make excuses, or take you to a factory they merely partner with.

- Pricing: Sometimes, unrealistically low prices can indicate a trader desperate for an order, possibly compromising on quality later. Extremely high prices might indicate multiple layers of intermediaries.

As a factory owner, I believe direct partnership offers the most transparency and control for serious buyers.

Conclusion

Finding reliable SPC manufacturers involves careful checks. Focus on verifying certifications, assessing production quality through QC insights and samples, demanding clear communication, using factory audits for proof, and confirming you’re dealing directly with a real factory. These steps protect your business and ensure quality flooring.

-

Explore how factory audits can enhance transparency and reliability in manufacturing processes, ensuring quality and compliance. ↩ ↩ ↩ ↩

-

Learn about the critical role of QMS in maintaining high standards and consistency in production, essential for any manufacturer. ↩ ↩ ↩

-

Discover the significance of social compliance in protecting brands and ensuring ethical practices in manufacturing environments. ↩ ↩ ↩