Are you tired of click lock flooring that is tough to install or does not last? Poor quality click systems can cause huge headaches, from slow installations to customer complaints. I will share how we ensure our click lock flooring delivers both top quality and easy installation.

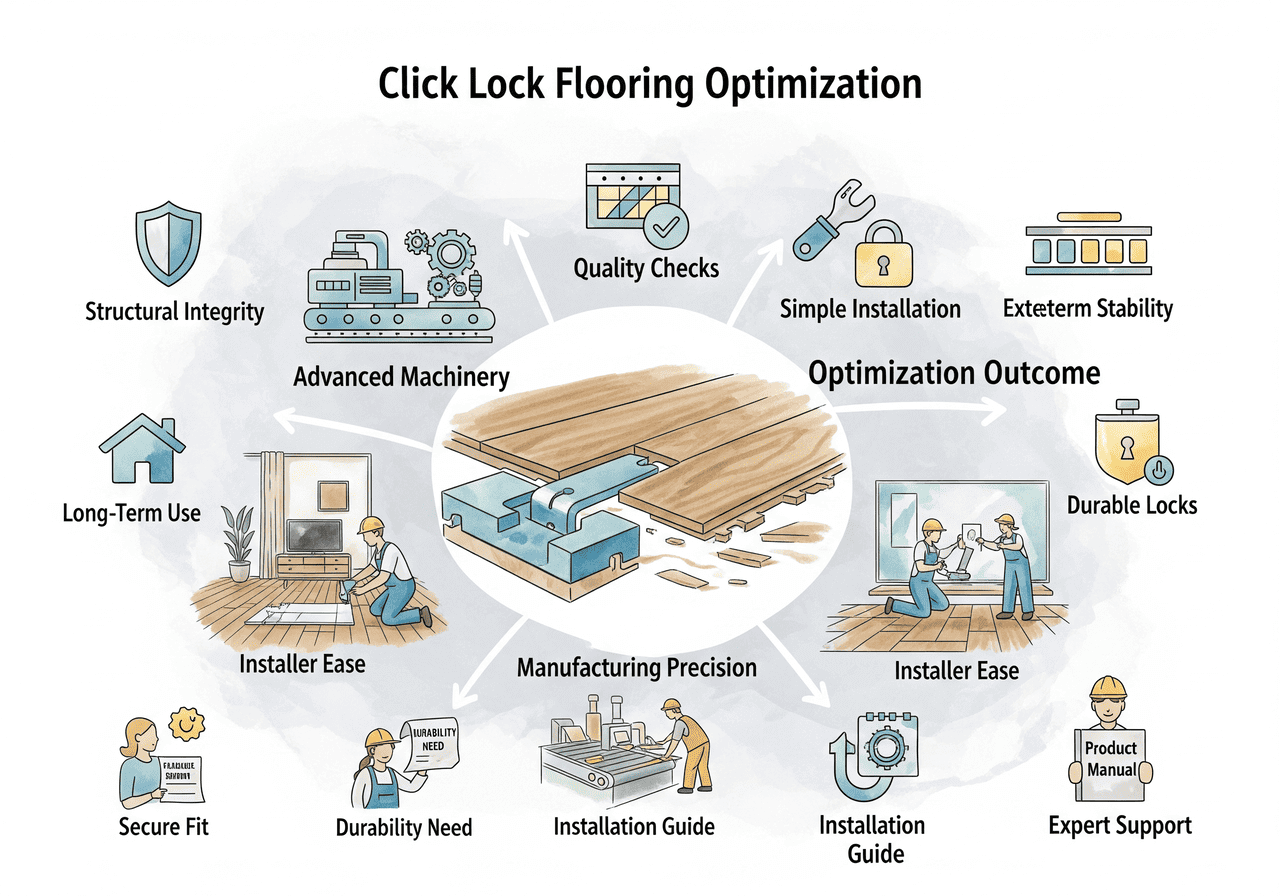

Optimizing click lock flooring means focusing on precision manufacturing, rigorous testing, and installer-friendly designs. We use advanced machinery and strict quality checks to guarantee tight, secure locks that make installation simple and ensure long-term durability.

You see, getting click lock flooring right is not just about the product itself. It is about the entire process, from design to delivery. We understand that your time and reputation are valuable. That is why I want to walk you through how we make sure our click lock flooring helps you succeed every time.

How do manufacturers ensure precise click lock quality?

Worried about inconsistent click lock quality from your suppliers? Poorly milled click systems lead to gaps, breakage, and frustrated installers. I will show you the steps we take to guarantee every plank has a perfect click lock.

Manufacturers ensure precise click lock quality through advanced milling technology, strict dimensional tolerances, and continuous in-line inspection. We use high-precision machines to cut profiles and conduct frequent checks to maintain exact specifications for a strong, reliable connection.

When we make click lock flooring at CloudsFlooring, precision is key. We invest in high-end, computerized numeric control (CNC) milling machines. These machines cut the click profiles with extreme accuracy. This ensures that every plank’s tongue and groove fit together perfectly. If the milling is off by even a tiny bit, the lock will not be strong. It might even break during installation.

We use advanced locking systems. These include systems like I4F and Uniclic. These systems are patented. They are designed to create very tight, waterproof connections. This helps prevent separation over many years of use.

We also have very strict quality control measures. Our team checks the dimensions of the click profile at every stage of production. This is not just a final check. It happens throughout the manufacturing process. We use specialized gauges and optical scanners. These measure the thickness, angle, and depth of the click system. We also track data for every batch. This helps us spot any small deviations quickly. It ensures that the click system is consistent from one plank to the next.

We select high-quality materials, too. Our materials are often certified by FloorScore and GreenGuard1. These certifications confirm good indoor air quality. This ensures the flooring is safe for homes with children or pets.

Here are key aspects of our quality assurance:

- Advanced Locking Systems: We utilize patented systems like I4F and Uniclic2. These ensure tight, waterproof connections. They prevent gaps and separation over time.

- Material Quality: We choose high-quality materials. These include wear layers from 22 to 30 mil. Our cores are moisture resistant. Certifications like FloorScore and GreenGuard confirm indoor air quality.

- Continuous Testing: Flooring undergoes rigorous testing. This includes locking strength, flatness, and gap checks. We follow industry standards like EN standards.

- Comprehensive Warranties: We offer limited lifetime residential warranties. We also provide 10+ year commercial warranties. These reflect our confidence in the product’s durability.

| Metric | Target Tolerance (mm) | Inspection Frequency | Method | Certifications | Warranty (Commercial) |

|---|---|---|---|---|---|

| Profile Height | ±0.05 | Hourly | Digital Caliper | FloorScore, GreenGuard | 10+ Years |

| Tongue Angle | ±0.5 degrees | Every 2 hours | Angle Gauge | ||

| Groove Depth | ±0.03 | Hourly | Optical Scanner | ||

| Locking Force | 50-70 N | Daily | Pull Test Machine |

This careful approach means our click locks are strong and reliable. It also makes installation easy for your team.

How can we test click lock strength?

Unsure if your current flooring will hold up after installation? Weak click locks can lead to flooring separating, causing costly callbacks and unhappy customers. I will explain the proven methods we use to test the strength of our click lock systems.

We test click lock strength using industry-standard pull tests and impact resistance tests. These methods simulate real-world stress, measuring the force required to separate planks and how well the lock endures drops, ensuring the flooring remains secure and stable over time.

At CloudsFlooring, we do not guess about click lock strength. We test it thoroughly. One main test is the pull test. We follow standards like ISO 24334. This test measures the tensile force at specific joint openings. For example, we measure the force needed to open a joint by 0.2mm (F 0.2mm). We also measure the maximum force at which the joint tears (F max). For semi-rigid click joints, we use a test speed of 5 mm/min. This ensures our locks are strong enough to prevent separation under daily use. A high force value means a strong lock. We target a specific force range to ensure durability. This ensures the floor will not come apart under normal use.

Another key test is the impact resistance test1. We drop a weighted object onto a locked joint from a certain height. This simulates objects falling onto the floor. If the click system holds without breaking or deforming, it passes. This test is important for areas with high traffic. It shows the lock can withstand everyday impacts.

We also perform temperature cycling tests2. This involves exposing the flooring to extreme hot and cold conditions. This checks if the click system remains stable as the material expands and contracts. This also ensures dimensional stability. We also test for moisture resistance. This checks if the locking system stays secure even when exposed to water.

Here is a summary of our strength testing methods:

- ISO 24334 Pull Test3: We measure the force to open a joint by 0.2 mm (F 0.2mm). We also measure the maximum tear force (F max). This simulates real-world stress.

- Durability Under Traffic: We subject flooring to simulated foot traffic. This ensures the locks hold over time.

- Moisture Resistance: We expose flooring to water. This ensures the locking system does not fail. This is crucial for waterproof flooring.

- Thermal Stability: We check if the locks hold when flooring expands or contracts. This happens due to temperature changes.

| Test Type | Purpose | Standard/Measure | Test Parameters (Example) |

|---|---|---|---|

| Pull Test | Measures locking force to prevent separation | ISO 24334 (F 0.2mm, F max) | 5 mm/min speed |

| Impact Resistance | Checks durability against dropped objects | No visible damage | Weighted object drop |

| Moisture Resistance | Ensures lock integrity under water exposure | Water immersion | No joint failure |

| Thermal Stability | Checks stability with temperature changes | Temperature cycling (-10°C to 60°C) | No deformation or gaps |

All these tests help us confirm that our click locks are robust and will perform well for a long time. They ensure that our flooring performs reliably in various conditions.

How do manufacturers help resolve installer issues?

Are your installers struggling with flooring that is hard to work with? Installation difficulties lead to project delays, increased labor costs, and unhappy clients. I will share how we actively work with installers to make our click lock flooring easy to lay.

Manufacturers help resolve installer issues by providing clear installation guides, offering training support, and using feedback to refine product design. We focus on making our click systems simple to engage, reducing the effort and time needed for a smooth, efficient setup.

We know that a great product is only half the battle. Easy installation is vital for our B2B partners like Aiden and Lori. This is why we focus on supporting installers. First, we design our click lock profiles to be user-friendly. They should connect with minimal effort but maximum security. We try to make the click sound clear when it locks. This gives installers instant feedback that the plank is correctly seated.

We provide very detailed installation guides. These are comprehensive, step-by-step instructions for our click lock LVT and SPC flooring. Our guides include clear instructions on how to prepare the subfloor. This means ensuring it is clean, smooth, flat, and dry. We also advise on acclimating the flooring at the correct temperature (65°F to 85°F) for 24 to 48 hours. This is crucial for stability. We recommend mixing planks from 2 to 3 cartons. This ensures a consistent appearance across the installed floor. We also specify staggering end joints by a minimum of 6 inches. This adds to the structural integrity and visual appeal.

Here is how we support installers:

- Detailed Installation Guides1: We provide comprehensive guides. These offer step-by-step instructions. They cover subfloor preparation and plank acclimation.

- Install Tips: We offer practical advice. This includes ensuring subfloor flatness. We also recommend mixing planks from different cartons. Staggering end joints is also key.

- Training and Technical Support2: We offer training sessions. We also provide technical support via helplines or online chats. This helps installers resolve issues quickly.

- Quality Control3: We maintain consistent product quality. This minimizes installation problems. Our products meet high standards.

- Warranty and After-Sales Service: Our warranties provide confidence. We offer after-sales support for resolving post-installation issues.

Beyond guides, we are open to feedback. If an installer faces a recurring issue, we want to know. We use this information to improve our product design. For example, some feedback led us to refine the bevel of our click edges. This made it easier to angle and drop the planks into place.

| Common Installer Pain Point | CloudsFlooring Solution | Benefit for Installers |

|---|---|---|

| Inconsistent fit | Precision manufacturing, strict tolerances | Reduced waste, faster work |

| Confusing instructions | Clear, detailed, step-by-step guides | Fewer errors, self-sufficiency |

| Difficult locking | User-friendly, optimized click profiles | Less fatigue, smoother install |

| Unforeseen site issues | Technical support (helpline, chat) | Quick problem resolution |

| Subfloor prep uncertainty | Specific subfloor requirements in guides | Proper base, lasting installation |

This complete support helps reduce common installation headaches. It ensures our flooring is easy to lay.

How do click profiles affect installation speed?

Is your flooring installation taking too long and costing too much? Inefficient click profiles1 can slow down projects, eating into your profits and frustrating your clients. I will explain how the right click profile can significantly boost your installation speed2 and efficiency.

Click profiles greatly affect installation speed by determining ease of engagement and connection stability. Well-designed, precise click systems allow planks to snap together quickly with minimal effort, reducing labor time and ensuring a secure, fast installation process for large projects.

The design of a click profile directly impacts how fast flooring can be installed. Some profiles are easier to angle and drop into place. Others require more force or specific techniques. At CloudsFlooring, we use click profiles that are known for their efficiency. For example, our 5G click system3 is very popular. This system allows installers to simply drop the plank down and click it into place. There is no need for excessive tapping or tricky angling. This design drastically reduces the time spent on each plank. This makes our flooring ideal for DIY projects. Many homeowners can complete a moderately sized room in a single day using our click lock flooring.

A faster installation speed is a huge advantage for our B2B clients. It means more projects can be completed in less time. This leads to lower labor costs and higher profits. For large commercial projects, this difference can be substantial. A profile that locks easily also reduces installer fatigue. Less fatigue means fewer mistakes and higher quality work.

Here is how click profiles enhance installation speed:

- Ease of Locking: Systems like Uniclic enable angling and snapping. This allows planks to lock together without glue or nails. This significantly reduces installation time.

- Reduced Learning Curve: Simpler profiles, suitable for DIY, require less skill and equipment. This speeds up installation for novices. Compared to tongue and groove systems, click systems are much faster.

- Minimal Tools Required: Most click lock systems are tool-free. Or they require only basic tools. For example, planks can be cut with a utility knife. This speeds up the process further.

- Compatibility and Consistency: Well-designed profiles ensure smooth locking. This minimizes delays. Reputable systems like I4F are known for reliability.

- Faster Completion: Click lock flooring is faster than traditional methods. Installations can often be completed in hours rather than days. This is ideal for busy projects.

We ensure that our click systems are consistent across all planks. Inconsistency slows down installation. Installers waste time trying to make mismatched planks fit. Our precision manufacturing ensures every plank fits perfectly. This makes for a smooth, continuous workflow on site. This translates directly into savings and efficiency for your business.

| Click Profile Type | Installation Method | Installation Speed (Relative) | Ease of Use | Typical Tools Needed |

|---|---|---|---|---|

| Angle-Angle | Angle, push, then drop | Standard | Medium | Tapping block, mallet |

| Angle-Tap | Angle, then tap to lock | Medium-Fast | Medium | Tapping block, mallet |

| Drop-Lock (5G-type) | Drop straight down, push | Fast | High | Utility knife |

Our goal is to provide click profiles that deliver both speed and quality for every project.

What ensures Click Lock’s long-term performance?

Worried about your click lock flooring failing after just a few years? Poorly designed or manufactured click systems can lead to gaps, breakage, and early floor replacement, costing you heavily. I will reveal the critical factors that guarantee our click lock flooring lasts for years.

Long-term click lock performance relies on high-quality virgin materials, robust profile design, and consistent manufacturing precision. These elements prevent issues like gapping or breakage under daily use and temperature changes, ensuring the floor remains stable and attractive for its lifespan.

Ensuring click lock flooring lasts for many years means focusing on quality from the very beginning. We use only high-grade virgin PVC for our LVT and SPC core materials. Virgin materials are more stable. They are less prone to brittleness or expansion/contraction issues compared to recycled materials. This material stability is crucial for the click system’s integrity over time. If the core material is unstable, the click profiles can weaken. This can lead to gapping or even breaking. We also use thick wear layers. These are typically 22 to 30 mil thick. A thicker wear layer provides better protection against scratches and scuffs. This ensures the floor looks good for longer.

Beyond material, the robustness of the click profile design itself is key. Our engineers design profiles that are not only easy to install but also strong enough. They must withstand daily foot traffic and furniture movement. They account for the forces that act on the click joint. This includes shear stress and tensile stress.

Proper installation is also a critical factor. For optimal performance, we recommend using a dense, closed-cell rubber underlayment. An example is Duraquiet 3mm. This type of underlayment provides excellent resilience, sound insulation, and moisture resistance. It has passed durability tests like the Robinson Test. This ensures it can withstand heavy foot traffic. It also offers high IIC ratings for soundproofing. This enhances comfort and stability. We advise against stapling underlayment, as this can reduce its acoustical properties. For areas with high moisture, a moisture barrier is essential under the underlayment.

Regular quality checks during production also play a big part. We constantly monitor the milling accuracy and material consistency. This prevents any small flaws from getting into the finished product. These flaws could compromise the long-term performance. We also ensure that our click systems are suitable for various climates. They perform well even with temperature and humidity changes. This complete approach ensures that our click lock flooring offers lasting performance and durability for your projects.

Here are key elements for long-term performance:

- Virgin Material Quality1: We use 100% virgin PVC/Stone Powder. This prevents brittleness and enhances stability.

- Robust Profile Design2: Our profiles are engineered for maximum strength. They withstand daily stress and prevent gapping.

- Manufacturing Precision3: We maintain sub-millimeter tolerances. This ensures consistent, tight connections.

- Suitable Underlayment: We recommend dense, closed-cell rubber. This offers resilience, sound insulation, and moisture resistance.

- Proper Installation: This includes subfloor preparation and moisture barriers.

- Temperature Stability: Our products are tested for extreme temperatures. They resist expansion and contraction.

- Regular Maintenance: Simple cleaning practices like sweeping and mopping. This preserves appearance and functionality.

- Comprehensive Warranties: We offer limited lifetime residential and 10+ year commercial warranties.

- Certifications: Certifications like FloorScore and GreenGuard confirm high durability standards.

| Factor | Impact on Long-Term Performance | CloudsFlooring Standard | Benefit Summary |

|---|---|---|---|

| Virgin Material Quality | Prevents brittleness, enhances stability | 100% Virgin PVC/Stone Powder | Stable, durable core foundation |

| Thick Wear Layer | Resists scratches, scuffs | 22-30 mil | Extended aesthetic and functional life |

| Robust Profile Design | Withstands daily stress, prevents gapping | Engineered for maximum strength | Secure, stable, and long-lasting joints |

| Proper Underlayment | Provides resilience, soundproofing, moisture resistance | Duraquiet 3mm (Rubber) | Enhanced comfort, protection from moisture |

| Installation Practices | Ensures stability, prevents issues | Clear guides, moisture barriers | Optimal floor integrity, fewer call-backs |

| Temperature Stability | Resists expansion/contraction issues | Tested for extreme temperatures | Maintains integrity in varied climates |

| Regular Maintenance | Preserves appearance & functionality | Easy cleaning instructions | Extends product lifespan, retains beauty |

This comprehensive approach guarantees a long-lasting and reliable flooring solution for all your projects.

Conclusion

At CloudsFlooring, we focus on precision, robust testing, and installer support to deliver top-quality, easy-to-install click lock flooring. This ensures your projects are smooth, profitable, and your customers satisfied.

The above data is for reference only.

-

Understanding the significance of virgin materials can help you choose durable flooring options that last longer and perform better. ↩ ↩ ↩ ↩ ↩

-

Exploring robust profile design will reveal how it contributes to the longevity and stability of your flooring investment. ↩ ↩ ↩ ↩ ↩

-

Learning about manufacturing precision can help you appreciate the quality assurance processes that lead to superior flooring performance. ↩ ↩ ↩ ↩