Is your kitchen floor showing signs of wear or water damage? A poor flooring choice can lead to big problems. Choosing the right material ensures a lasting, functional, and beautiful kitchen.

The best kitchen flooring is 100% waterproof, durable, and easy to clean. Materials like SPC and LVT are excellent choices, offering both resilience and style for busy kitchen environments, especially for buyers like those I work with at CloudsFlooring.

When I speak with clients, whether they are distributors or large company buyers, the kitchen often comes up. It is a high-traffic, high-moisture area. This means the flooring needs to stand up to a lot. I always tell them we need to balance performance, aesthetics, and practicality. Let’s look closely at what truly makes a kitchen floor optimal.

Why is 100% waterproof performance non-negotiable for kitchen flooring?

Does your kitchen often have spills or splashes? Moisture is a constant threat in any kitchen. Skipping truly waterproof flooring can lead to big issues later. It’s a non-negotiable feature for durability and hygiene.

100% waterproof performance is critical for kitchen flooring because it prevents water damage to the subfloor and the floor itself. It stops mold growth, protects structural integrity, and ensures the flooring’s longevity, which is something I always emphasize to our clients at CloudsFlooring.

The kitchen is a place where water is always present. We cook, we wash dishes, and spills happen often. From my experience at CloudsFlooring, I have seen how quickly even small amounts of water can cause damage if the flooring is not fully waterproof. This is why when I work with our LVT and SPC products, I know they offer this crucial protection.

Protecting Against Water Damage

When water sits on a floor that is not waterproof, it seeps into the seams and gaps. This can go down to the subfloor. Over time, this leads to rot and decay. For example, if you have wood subfloors, water will warp them. This creates uneven surfaces. This can also compromise the structural integrity of the entire floor system. I have helped clients, like Aiden in the UK, understand that this initial investment in waterproof flooring saves huge costs later. Research shows that non-waterproof flooring can absorb moisture, leading to significant damage.

Preventing Mold and Mildew

Water also creates a perfect environment for mold and mildew1. These grow in damp, dark places, especially underneath flooring. Mold not only causes bad smells but it also harms indoor air quality. It can trigger allergies and breathing problems for people. For a commercial kitchen, this is a huge health and safety risk. Our SPC and LVT flooring products are designed to stop this. They create a barrier that keeps water out. This protects the health of everyone using the kitchen.

Ensuring Longevity and Hygiene

A truly waterproof floor lasts much longer. It resists swelling, warping, and delamination caused by moisture. This means less need for costly repairs or replacements. It also makes cleaning much easier. Spills stay on the surface. You can just wipe them up quickly. This helps maintain a hygienic kitchen environment. It ensures the floor looks good for many years. Choosing LVP, LVT, or porcelain tiles ensures this durability and hygiene.

Waterproofing Comparison for Common Flooring Types

| Flooring Type | Waterproof Level | Key Benefit | Potential Issue |

|---|---|---|---|

| SPC/LVT Vinyl | 100% Waterproof | Prevents all water damage2 | Seams can be a weak point |

| Ceramic Tile | 100% Waterproof | Very durable, no water absorption | Grout can absorb water |

| Hardwood | Not Waterproof | Natural look | Warping, mold with moisture |

| Laminate | Water Resistant | Affordable | Swells with standing water |

| Engineered Wood | Water Resistant | More stable than solid wood | Still prone to moisture damage |

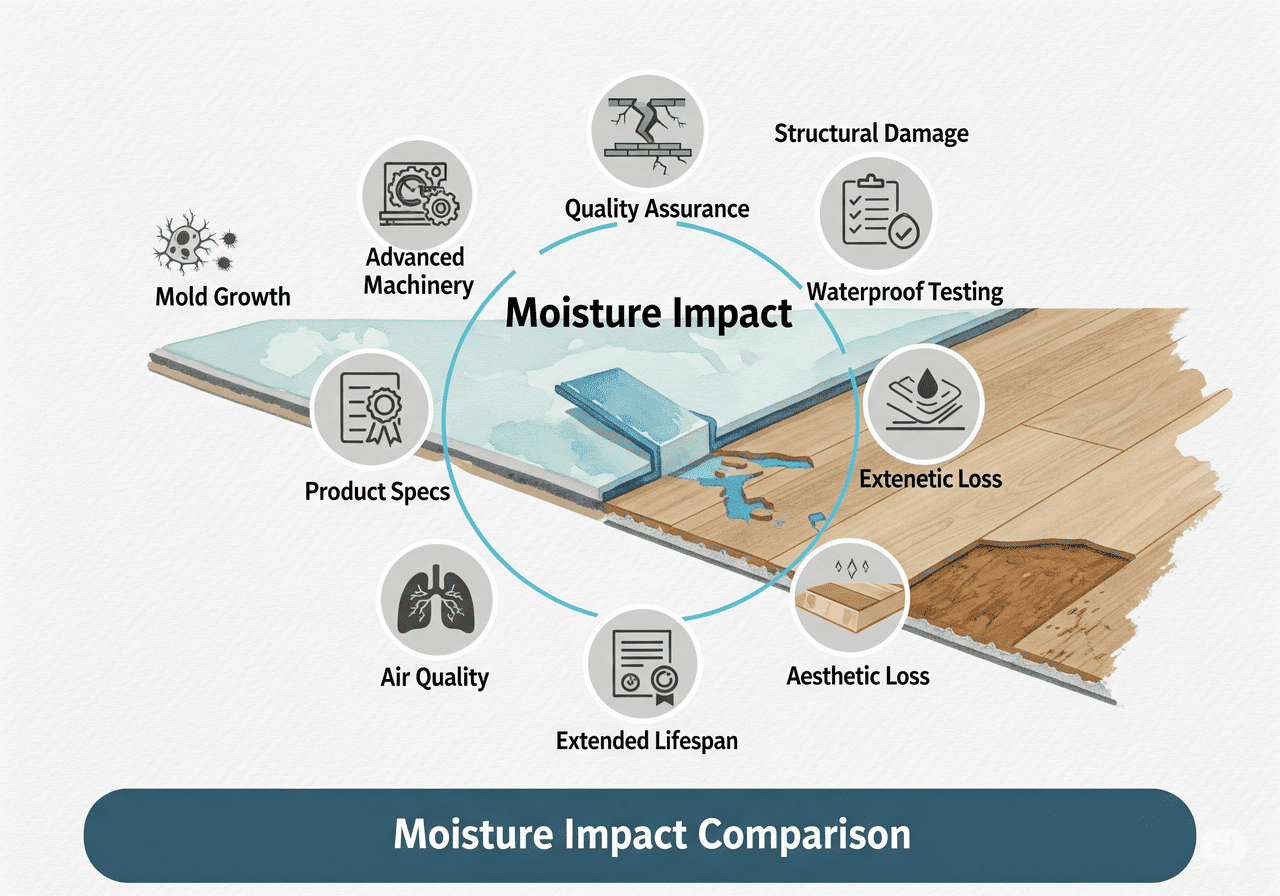

What are the consequences of moisture penetration on kitchen flooring and subfloor?

Are you worried about water getting under your kitchen floor? Moisture penetration can cause damage you cannot see right away. This leads to expensive and unhealthy problems.

Moisture penetration leads to serious problems like mold growth, structural damage to subfloors, and unpleasant odors. It also ruins the appearance of the flooring, causing warping or lifting. As I tell our distributors, stopping moisture is key to protecting the kitchen’s long-term health and value.

I have heard many stories from buyers, including Lori from the United States, about floors that failed because of moisture. These stories often start with a small leak or a forgotten spill. Then they turn into major headaches. Understanding these consequences helps us appreciate why quality waterproof flooring is so important.

Health Risks from Mold and Mildew

When water gets trapped under flooring, it creates a damp, dark space. This is where mold and mildew love to grow. Mold spores spread into the air. They can cause respiratory problems. They also cause allergies. Some types of mold can even be toxic. For a commercial kitchen, this is a huge health and safety risk. It can lead to health code violations. My factory at CloudsFlooring focuses on products that stop this growth. This protects the health of everyone using the kitchen. Mold growth from moisture penetration1 can also cause respiratory issues and other health problems, especially in poorly ventilated kitchens.

Structural Damage to Subfloors

The subfloor is the base beneath your visible flooring. Most subfloors are wood or particleboard. These materials absorb water easily. When they get wet, they swell and warp. This makes the surface uneven. It can also weaken the overall structure of the floor. Over time, this can lead to sagging or even collapse in extreme cases. Moisture that seeps through the flooring can damage the subfloor, causing wood to rot or concrete to develop mold. Replacing a damaged subfloor is a huge, costly, and time-consuming job. This is why choosing a flooring that stops water at the surface is essential.

Aesthetic and Functional Deterioration

Beyond the hidden damage, moisture also ruins the look of your flooring. Non-waterproof materials, such as solid hardwood or laminate, can swell, buckle, or delaminate when exposed to moisture. This results in uneven surfaces, tripping hazards, and a compromised aesthetic, often necessitating premature replacement. Grout lines in tile can discolor and crumble. Hardwood will warp and rot. This makes the kitchen look old and uncared for. It also affects the floor’s function. Uneven surfaces can be tripping hazards. It also makes cleaning harder. For our clients, selling visually appealing and durable flooring is crucial. Damaged flooring detracts from the kitchen’s appearance and functionality, potentially lowering the home’s resale value.

Impact of Moisture Penetration on Flooring & Subfloor

| Problem Area | Impact of Moisture | Long-Term Consequence |

|---|---|---|

| Indoor Air Quality | Mold and mildew growth, musty odors | Respiratory issues, allergies, unpleasant environment |

| Subfloor Integrity | Wood rot, swelling, warping, weakened structure | Sagging floors, costly repairs, structural instability |

| Flooring Appearance | Swelling, buckling, delamination, discoloration | Unsightly floor, reduced property value, need for replacement |

| Hygiene | Trapped moisture, breeding ground for bacteria | Difficulty in cleaning, unsanitary conditions |

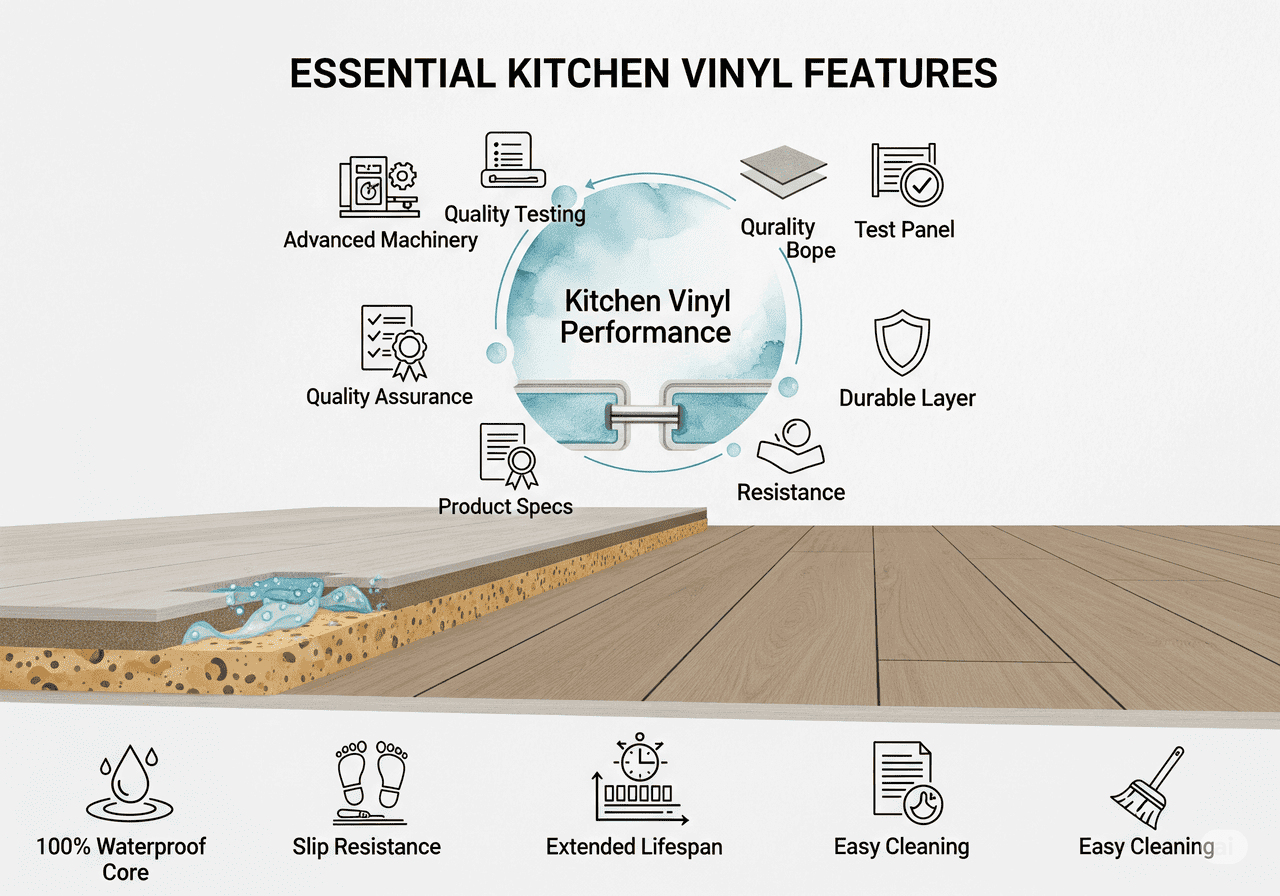

What are the essential performance features for kitchen vinyl flooring?

Are you considering vinyl flooring for your kitchen? Not all vinyl is the same. Knowing the key features ensures you pick the best product for durability and function.

Essential performance features for kitchen vinyl flooring include 100% waterproof capabilities, a strong wear layer for durability, and ease of cleaning. Additionally, good vinyl flooring should offer slip resistance, stain resistance, and sound absorption for a safer and more comfortable kitchen environment.

When I talk to clients like Aiden from the UK about LVT and SPC flooring for kitchens, I always highlight specific features. These are what make our products from CloudsFlooring stand out. They are not just about looks. They are about long-term performance in a tough environment.

Waterproof Core Technology

The most vital feature is a truly waterproof core. Our SPC (Stone Plastic Composite) and WPC (Wood Plastic Composite) products have this. SPC, for example, has a rigid core made of stone powder and PVC. This makes it completely impervious to water. Water will not cause it to swell or buckle. This is a big advantage over traditional laminate or even some engineered wood. For busy kitchens, this protection is non-negotiable. It stops any water from reaching the subfloor.

Durable Wear Layer1

The wear layer is the top protective coating of the vinyl plank. It protects the floor from scratches, scuffs, and daily wear. For kitchens, you need a thick and robust wear layer. Look for one that is at least 20 mil (0.5mm) for residential use to handle heavy foot traffic. For commercial kitchens, I recommend 28 mil (0.7mm) or more. A thicker wear layer means the floor will look good for many years. It stands up to heavy foot traffic and dropped items like pots and pans. My factory, CloudsFlooring, offers customized wear layers to meet specific needs.

Slip Resistance2, Stain Resistance, and Easy Maintenance

Kitchens can get wet. So, slip resistance is very important for safety. Look for vinyl flooring with a textured surface or a good slip resistance rating. This helps prevent falls. Stain resistance is also key. The flooring needs to be easy to clean and resistant to stains from food, grease, and liquids. Easy cleaning is another crucial feature. Vinyl flooring should be simple to wipe clean. It should not need special cleaners. This saves time and effort. It also helps maintain a hygienic space. Our products are designed for fast cleanup and minimal upkeep.

Comfort and Installation Ease

A good kitchen floor should also provide a comfortable feel underfoot. This is important for standing for extended periods while cooking or cleaning. Many vinyl options, especially LVP with attached underlayment, offer this cushioning. Installation ease is another benefit. Many vinyl options feature click-lock systems. This allows for quick and simple installation without adhesives or professional help, making them ideal for DIY projects or efficient commercial setups. This versatility in design allows matching various kitchen aesthetics.

Key Performance Features of Optimal Kitchen Vinyl Flooring

| Feature | Description | Benefit for Kitchens | CloudsFlooring Advantage |

|---|---|---|---|

| 100% Waterproof Core | Impervious to water; often SPC or WPC | Prevents subfloor damage, mold, and flooring distortion | Our LVT/SPC products are naturally 100% waterproof |

| Durable Wear Layer | Protective top coating; thickness matters | Resists scratches, dents, and scuffs from daily use | Customizable wear layers (e.g., 28mil for commercial) |

| Slip Resistance | Surface texture or coating for grip | Reduces risk of slips and falls on wet surfaces | Products often have textured finishes for better grip |

| Stain Resistance | Non-porous surface that resists stains | Maintains hygiene, prevents discoloration | Easy to clean, repels food/grease stains |

| Easy to Clean | Simple wipe-up; no special cleaners needed | Saves time, maintains hygiene | Low maintenance, just sweep and damp mop |

| Comfort Underfoot | Provides a soft, cushioned feel | Important for extended standing periods | SPC core and optional underlayment provide comfort |

| Installation Ease | Click-lock systems or simple methods | Quick and simple installation, reduces labor costs | Designed for efficient, straightforward installation |

What practical alternatives to vinyl flooring exist for kitchens, and what are their pros and cons?

Are you exploring all your kitchen flooring options? Vinyl is popular, but other materials exist. Knowing their good and bad points helps you decide what is best for your needs.

Practical alternatives to vinyl flooring for kitchens include ceramic tile, natural stone, and engineered hardwood, but each has distinct pros and cons. Ceramic tile is highly waterproof and durable, while natural stone offers a premium look. Hardwood, however, generally lacks waterproof capabilities and needs more care in a kitchen setting.

When a client asks me about options other than LVT or SPC for their kitchen, I always give them a full picture. At CloudsFlooring, we specialize in vinyl, but I want our partners to understand why our products are often the best choice compared to others.

Ceramic and Porcelain Tile

Pros: These are very durable and 100% waterproof when installed correctly. They are easy to clean and resist stains and scratches. They come in many styles and colors. They are long-lasting and suitable for both residential and commercial use.

Cons: Tile can be very hard and cold underfoot. It can break dishes if dropped. Grout lines can collect dirt and mold over time if not sealed properly. Installation can be labor-intensive and costly, often requiring professional help.

Natural Stone1 (Granite, Marble, Travertine)

Pros: Stone offers a luxurious and unique look. It is very durable and adds significant value. It can last a lifetime with proper care. It provides an elegant, high-end feel to kitchens.

Cons: Stone is usually very expensive, both for material and installation. It is very hard and cold. Some stones are porous and need regular sealing to prevent stains. They can also be slippery when wet. It is generally high-maintenance.

Hardwood Flooring

Pros: Hardwood offers a timeless and warm aesthetic. It adds value to a home. It can be refinished multiple times to renew its look.

Cons: This is generally not recommended for kitchens due to moisture sensitivity. Water spills can cause warping, swelling, and mold growth. It scratches and dents more easily than other options from dropped items or heavy traffic. It requires more maintenance and is often not a good fit for high-traffic, wet areas. From my experience with Lori, our client in the US, she would be very hesitant about using hardwood in a high-volume kitchen due to the risk of damage and callbacks.

Engineered Wood2

Pros: This is more stable than solid hardwood and less prone to warping from moisture. It has a real wood veneer, offering a natural look. It can offer a good return on investment for home resale.

Cons: While more stable, it is still not fully waterproof. It can still be damaged by standing water. The top veneer layer can scratch. It cannot be refinished as many times as solid hardwood. It is also more expensive than vinyl.

Laminate

Pros: This is an affordable option. It is easy to install, often with click-lock systems. It comes in a variety of designs mimicking wood or tile.

Cons: It is not fully waterproof. It is susceptible to moisture damage through seams, which can cause swelling. It is generally less durable than vinyl in high-traffic areas.

Comparison of Kitchen Flooring Alternatives

| Flooring Type | Pros | Cons | Best Use |

|---|---|---|---|

| Vinyl (LVP/LVT) | Waterproof, durable, affordable, easy to install, versatile designs, wide appeal | Some lower-end products might not be as durable | Residential, commercial kitchens |

| Engineered Hardwood | Beautiful, durable, moisture-resistant, good ROI, warm feel | Expensive, requires maintenance, not fully waterproof | Residential kitchens |

| Ceramic/Porcelain Tile | Waterproof, durable, easy to clean, wide style range, long-lasting | Cold, hard, professional installation, grout maintenance | Residential, commercial kitchens |

| Laminate | Affordable, easy to install, wood/tile designs | Not waterproof, less durable, moisture damage risk | Residential kitchens |

| Natural Stone | Elegant, durable, unique, luxurious | Expensive, high maintenance, cold, hard | High-end residential kitchens |

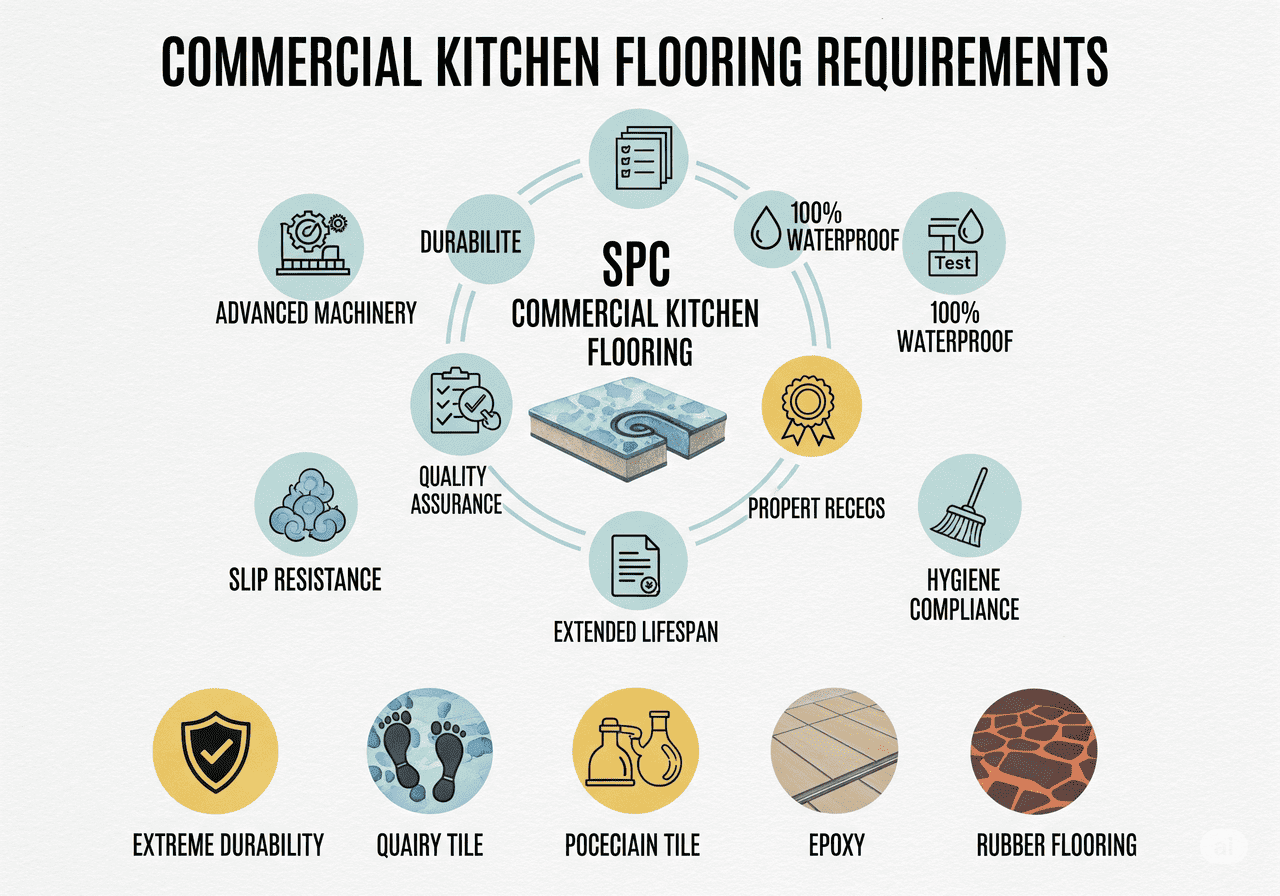

What specific requirements and suitable materials exist for commercial kitchen flooring?

Are you designing a commercial kitchen? The flooring here faces extreme demands. Standard home flooring will not work. Knowing specific needs helps you choose the right materials.

Commercial kitchen flooring needs to be extremely durable, highly slip-resistant, and 100% waterproof. It must also resist chemicals, be easy to clean, and meet strict hygiene standards. SPC and LVT are highly suitable, but options like quarry tile, porcelain, and epoxy coatings also meet these tough demands.

When I consult with large-scale buyers, especially those looking for flooring for restaurants or hotel kitchens, the requirements are much stricter than for residential homes. As a factory in China, CloudsFlooring has supplied to projects where these standards are paramount. My team understands these intense needs.

Key Performance Requirements for Commercial Kitchens

Commercial kitchens have constant heavy traffic. They have spills of water, oil, and food. They also use strong cleaning chemicals.

- Extreme Durability: The flooring must withstand heavy foot traffic, rolling carts, and dropped equipment. It needs to resist abrasions, impacts, and punctures.

- 100% Waterproof and Chemical Resistance: Water and other liquids are common. The floor must not absorb anything. It must also resist damage from grease, acids, and strong cleaning agents.

- Superior Slip Resistance: Safety is number one. Floors must provide good grip, even when wet or greasy. This prevents accidents for staff. It needs to meet standards like OSHA’s coefficient of friction (COF) ≥0.5 or Pendulum Test Value (PTV) ≥36.

- Hygiene and Cleanability: The floor must be easy to clean and sanitize. Seamless surfaces or minimal grout lines prevent bacterial growth and simplify cleaning. It needs to meet local health codes.

- Regulatory Compliance: The flooring must meet health and safety codes, including fire resistance and hygiene standards.

Suitable Materials for Commercial Kitchens

Based on these requirements, here are some top choices:

- Heavy-Duty SPC1 (Stone Plastic Composite) Flooring: My factory, CloudsFlooring, produces SPC with thick wear layers (0.5mm or 0.7mm) which is ideal. Its rigid core is completely waterproof and stable. It handles heavy loads well. It is easy to clean. It also offers good slip resistance with textured finishes. This is a top choice for its balance of performance and cost. It often has antimicrobial properties for hygiene.

- Quarry Tile / Porcelain Tile: These are classic choices for commercial kitchens. They are very durable, slip-resistant, and can withstand high temperatures. They are also resistant to chemicals. Porcelain is often preferred for its lower porosity and ease of cleaning compared to traditional quarry tile. However, grout lines can still be a maintenance issue.

- Epoxy Flooring2: This is a seamless, poured-in floor. It is highly resistant to chemicals, abrasions, and moisture. It offers excellent hygiene. Installation requires skilled labor and proper curing time. It can also be very hard underfoot. Anti-slip additives are often required to prevent slipperiness.

- Rubber Flooring: This is a good option for specific areas within a commercial kitchen where comfort and slip resistance are paramount. It is highly slip-resistant and comfortable underfoot. It is durable but may show wear over time.

These materials ensure compliance with commercial kitchen standards, prioritizing safety and cleanliness.

Commercial Kitchen Flooring Material Comparison

| Material Type | Durability | Waterproof Level | Slip Resistance | Chemical Resistance | Maintenance/Hygiene | Cost Range (Installed) |

|---|---|---|---|---|---|---|

| Heavy-Duty SPC | Excellent | 100% Waterproof | Good (textured) | Good | Easy to clean | $4.00 – $8.00/sq.ft. |

| Quarry/Porcelain Tile | Excellent | 100% Waterproof | Very Good | Excellent | Grout needs care | $6.00 – $12.00/sq.ft. |

| Epoxy Flooring | Excellent | 100% Waterproof | Good (additives) | Excellent | Very easy to clean | $7.00 – $15.00/sq.ft. |

| Commercial LVT | Very Good | 100% Waterproof | Good (textured) | Good | Easy to clean | $3.00 – $7.00/sq.ft. |

| Rubber Flooring | Good | Water resistant | Excellent | Moderate | Easy to clean | $4.00 – $10.00/sq.ft. |

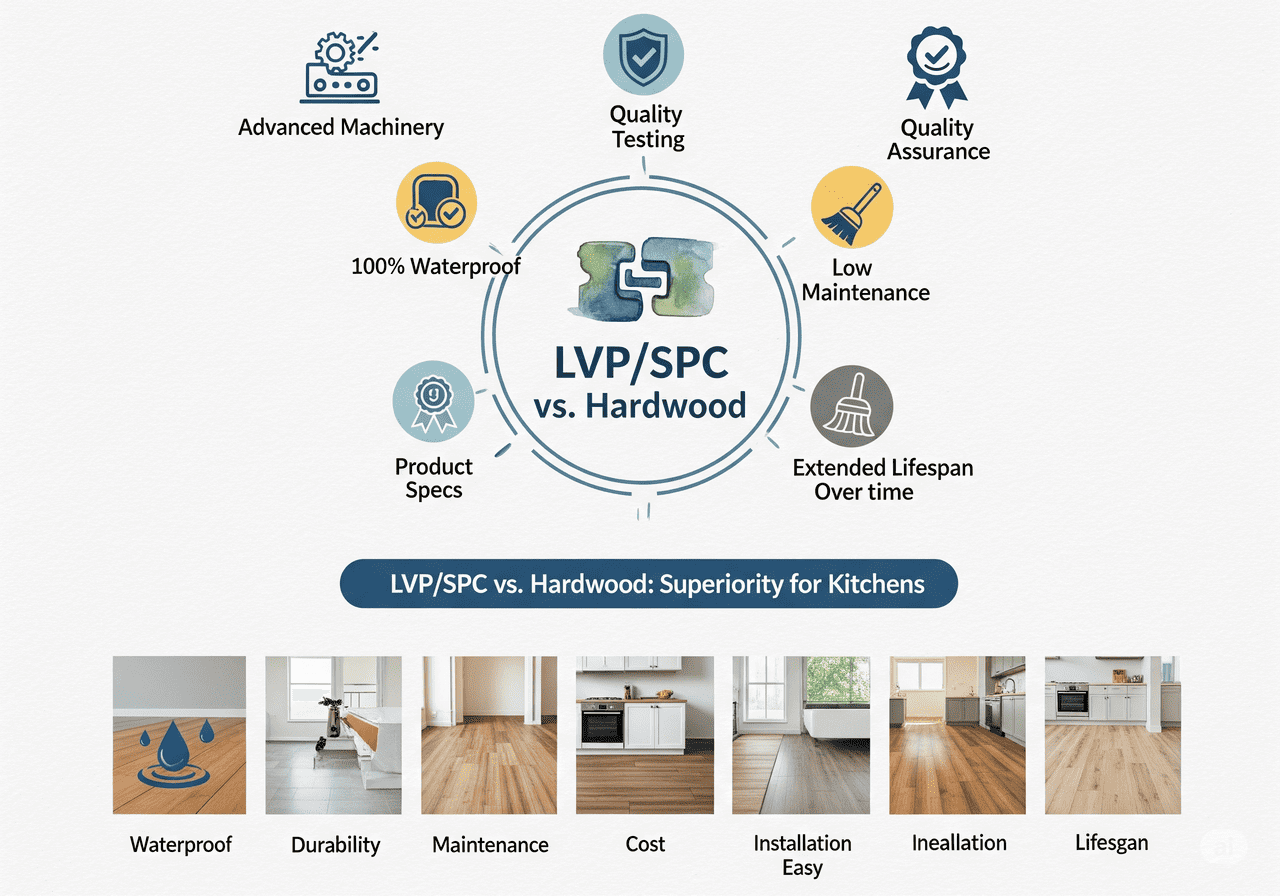

How can LVP/SPC be effectively marketed as a superior alternative to hardwood in kitchens?

Are you selling flooring and need to highlight LVP/SPC over hardwood for kitchens? Hardwood has a classic appeal, but LVP/SPC offers clear practical advantages. You need to show these.

LVP/SPC can be effectively marketed as superior to hardwood in kitchens by emphasizing its 100% waterproof nature, extreme durability against scratches and dents, and significantly easier maintenance. Highlighting its authentic wood look without hardwood’s common kitchen downsides resonates strongly with buyers.

When I speak with large distributors, like Aiden, who are looking to source high-quality vinyl flooring, I always make sure they understand the strong selling points of LVP and SPC, especially against traditional hardwood. Hardwood might be seen as premium, but for kitchens, it just doesn’t measure up. My factory, CloudsFlooring, has perfected LVT and SPC to overcome hardwood’s weaknesses.

Addressing Hardwood’s Weaknesses in Kitchens

Hardwood’s biggest problem in kitchens is moisture. Water spills cause warping, swelling, and eventually rot and mold. This is a constant worry for homeowners and a major headache for buyers like Lori who want to avoid product failures. Hardwood also scratches and dents easily from dropped pots or heavy appliances. It needs regular refinishing, which is costly and disruptive. It is also more expensive initially, making it a high-end investment.

Highlighting LVP/SPC’s Key Advantages

LVP (Luxury Vinyl Plank) and SPC (Stone Plastic Composite) directly address these issues.

- 100% Waterproof: This is the ultimate selling point. LVP and SPC cores are impervious to water. Spills sit on the surface and can be wiped clean. This means no warping, no mold, no subfloor damage. I often show samples to demonstrate this.

- Superior Durability1: Our LVP and SPC products feature robust wear layers and rigid cores. They resist scratches, dents, and scuffs much better than hardwood. SPC’s stone-plastic core specifically resists dents and impacts, ensuring long-term performance even in busy kitchens.

- Cost-Effectiveness: LVP and SPC are generally more affordable than hardwood, both for the material and installation. They also save money on long-term maintenance, making them a more practical choice.

- Easy Installation: Many LVP/SPC options feature click-lock systems, allowing for quick and simple, DIY-friendly installation. This reduces labor costs significantly compared to hardwood’s complex installation.

- Low Maintenance2: LVP and SPC are incredibly easy to clean. A simple sweep and damp mop are enough. No special cleaners, refinishing, or sealing are needed. This saves time and effort for homeowners.

- Authentic Appearance: Modern LVP and SPC technology allows for incredibly realistic wood-look designs. They mimic wood grain, texture, and color perfectly. Clients can get the warmth and beauty of hardwood without its vulnerabilities. At CloudsFlooring, we focus on rare and attractive styles to match any kitchen decor.

- Comfort and Sustainability: LVP/SPC, especially with attached underlayment, can provide a more cushioned feel underfoot than hardwood. Some products also incorporate recycled materials, appealing to environmentally conscious consumers.

Marketing Strategies for LVP/SPC

When marketing LVP/SPC to buyers and end-users, focus on these points:

- Visual Comparisons: I advise my clients to use side-by-side displays. This shows LVP/SPC’s realistic wood-like appearance next to hardwood, emphasizing that the aesthetics are often indistinguishable.

- Highlight "Worry-Free" Living: Emphasize the peace of mind that comes with a 100% waterproof3, durable floor. There is no more fear of spills or damage in the kitchen.

- Showcase Aesthetics: Use high-quality photos and samples. Demonstrate the realistic wood looks that can match any design style. We at CloudsFlooring provide excellent product photography for this.

- Emphasize Value: Discuss the long-term savings on maintenance and replacement costs. This is important for our B2B clients who care about return on investment.

- Showroom Demonstrations: Allow customers to test LVP/SPC’s waterproofing and scratch resistance in store settings. This hands-on experience convinces them of its superiority.

- Warranty Emphasis: Promote extended warranties (e.g., lifetime residential, 10+ years commercial) to build confidence in long-term performance.

- Eco-Friendly Messaging: Highlight sustainable manufacturing processes and the use of recycled materials in some products to appeal to environmentally conscious buyers.

LVP/SPC vs. Hardwood in Kitchens

| Feature | LVP/SPC | Hardwood | Superiority |

|---|---|---|---|

| Waterproof | 100% waterproof core | Not waterproof, prone to water damage, swelling, mold | LVP/SPC |

| Durability | Excellent; resists scratches, dents, impacts | Susceptible to scratches, dents, wear from kitchen use | LVP/SPC |

| Maintenance | Low; damp mop, no special care, no refinishing | High; needs specific cleaning, periodic refinishing | LVP/SPC |

| Appearance | Highly realistic wood look (customizable) | Natural wood aesthetic | Tie (preference) |

| Cost | More affordable (material + installation) | Generally more expensive, higher initial investment | LVP/SPC |

| Installation Ease | Easy click-lock, DIY-friendly | Requires professional installation, more complex | LVP/SPC |

| Lifespan in Kitchen | Long-lasting, stable, low risk of damage | Shorter due to moisture risk, needs more care, higher risk of replacement | LVP/SPC |

Conclusion

Choosing optimal kitchen flooring is about prioritizing waterproof performance, durability, and easy cleaning. While alternatives exist, LVP and SPC flooring from CloudsFlooring stand out as superior, combining beauty with unmatched practical benefits for both residential and commercial kitchens.

The above data is for reference only.

-

Discover why LVP’s superior durability makes it a smart choice for busy kitchens, protecting against scratches and dents. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the low maintenance benefits of LVP, making it an ideal flooring option for homeowners looking for convenience. ↩ ↩ ↩ ↩ ↩

-

Explore this link to understand how 100% waterproof flooring can transform your kitchen experience, ensuring durability and ease of maintenance. ↩