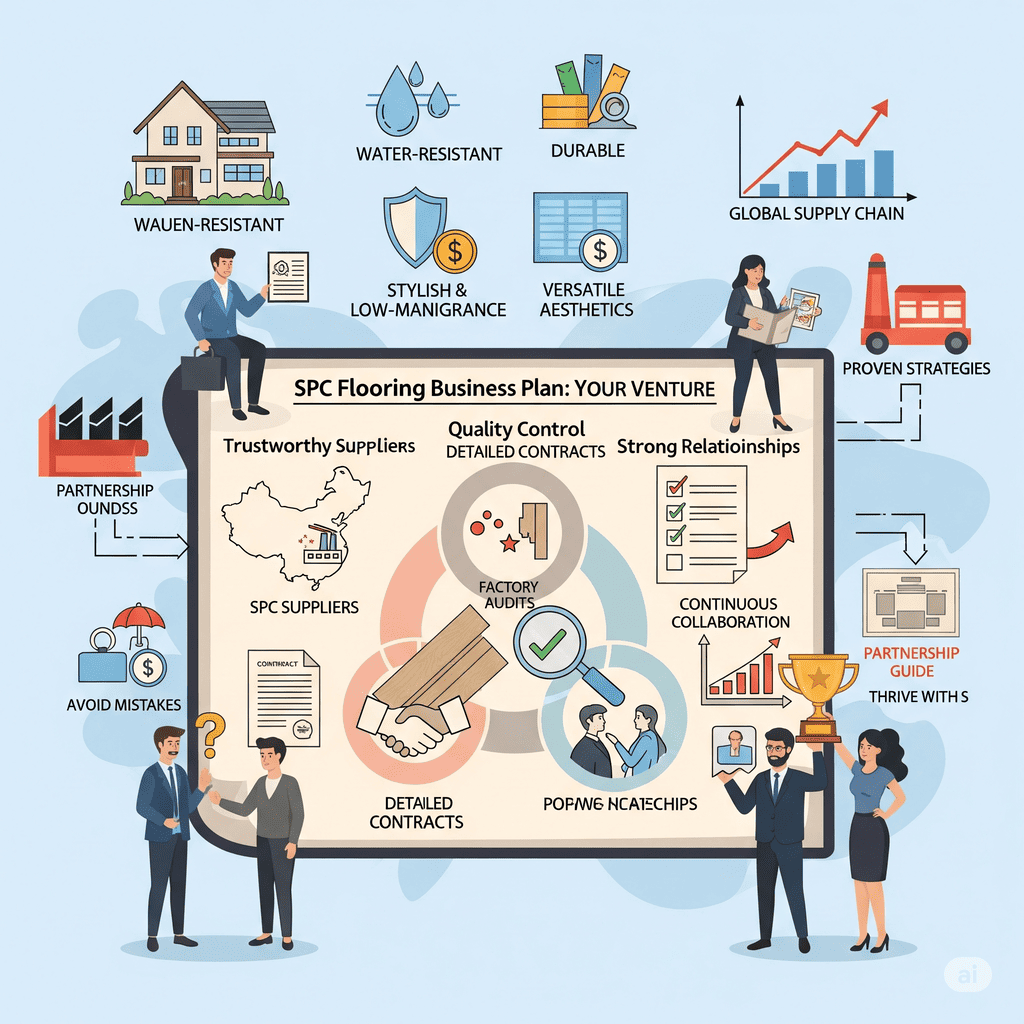

Starting a flooring business can feel overwhelming. Finding the right partners and avoiding costly mistakes is hard. I will share proven strategies to build your successful SPC flooring venture.

A successful SPC flooring business starts with selecting trustworthy SPC suppliers, understanding crucial quality control, and building strong relationships. Focus on detailed contracts, rigorous factory audits, and continuous performance tracking for this durable, water-resistant, and versatile product.

Building a thriving SPC flooring business means more than just finding a product. It is about forging strong partnerships and understanding the finer details of the supply chain. SPC flooring is a leading choice for its durability, water resistance, affordability, and aesthetic versatility. The flooring industry is projected to grow significantly, driven by consumer demand for stylish, low-maintenance options. This guide outlines the key steps to launch and grow your SPC flooring business, tailored to its unique characteristics, focusing on selecting and working with factory partners from regions like China.

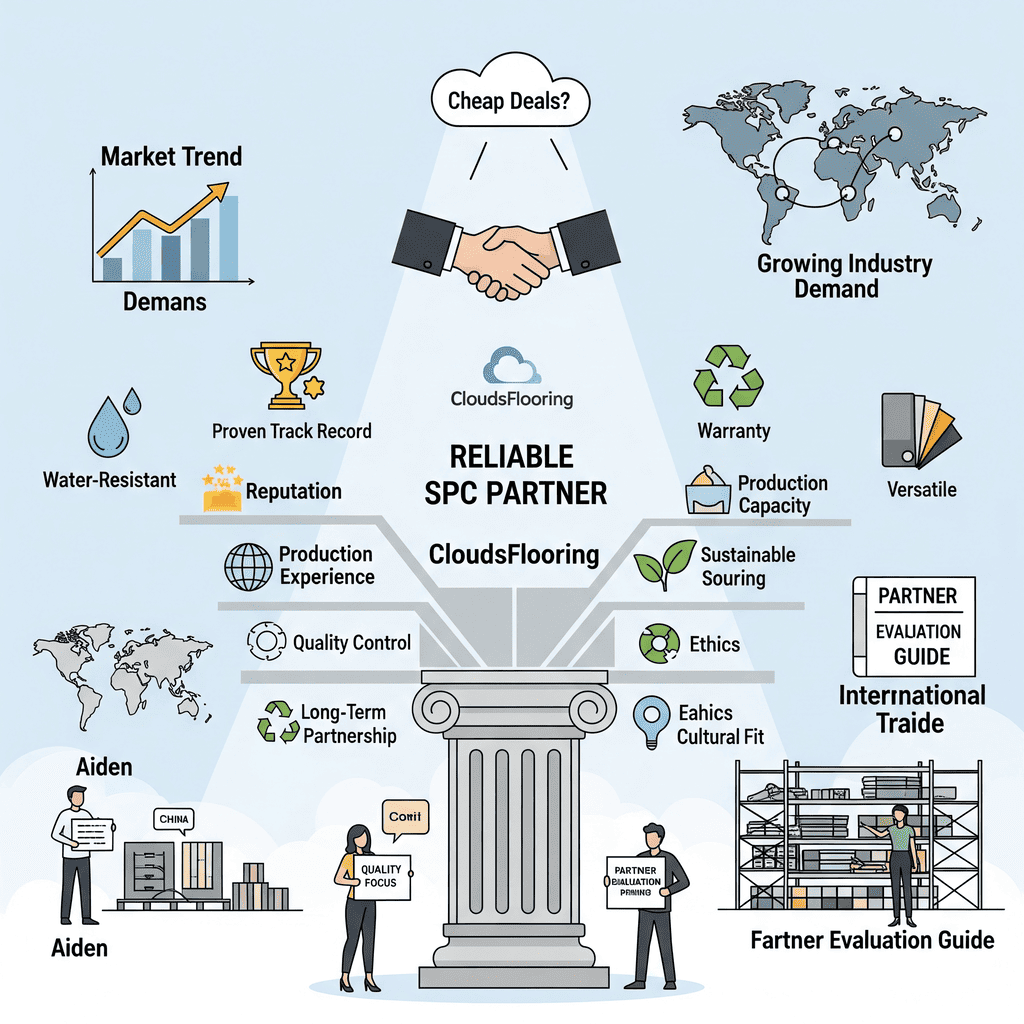

Beyond price, what are the essential hallmarks of a reliable SPC flooring factory partner?

You want low prices, but quality matters more for SPC flooring. Cheap deals can hide big problems later. A true partner offers more than just a good number.

A reliable SPC flooring factory partner shows consistent quality, strong communication, and ethical practices. They have relevant certifications, a stable production process, and excellent after-sales support, ensuring product consistency.

When I look for partners or advise new clients like Aiden and Lori, I always emphasize looking past just the price tag. A reliable SPC flooring factory partner is not just about the lowest quote. They demonstrate consistent quality through robust internal quality control systems, like ISO 9001 certification. This shows they have a proven system for managing production. My factories, CloudsFlooring, uphold these stringent quality standards.

They also have an established reputation and extensive experience in the industry. Look for manufacturers with a proven track record and positive customer feedback. Companies like Xtrancore and Responsive Industries are recognized for quality and reliability. This experience means they understand the nuances of SPC production and international trade.

Crucially, they possess relevant certifications and compliance. Look for certifications like ISO 9001 for quality management, ISO 14001 for environmental management, FloorScore for low VOC emissions (especially vital for North American markets), and CE Marking for EU compliance. These certifications are not just pieces of paper; they ensure adherence to international standards and product safety.

A reliable partner offers robust quality control at every stage. This means they implement strict quality checks from raw material inspection (ensuring the quality of limestone powder, PVC resins, and wear layers), through in-process checks during extrusion, lamination, and cutting, right up to final product testing. This comprehensive approach ensures consistent product quality from batch to batch.

They also offer excellent after-sales support1 and a clear warranty. A comprehensive warranty (e.g., a 30-year limited residential warranty) and responsive customer service are critical for addressing any post-purchase issues that may arise. This shows their confidence in their product and their commitment to long-term partnership.

Furthermore, top-tier suppliers have supply chain efficiency2. They manage logistics effectively, partnering with reliable freight forwarders to ensure on-time delivery for international orders. This includes proper packaging, container loading, and documentation for smooth customs clearance. Lastly, cultural compatibility is vital. For Chinese manufacturers, a willingness to build “guanxi” (relationships) through respectful, patient, and proactive communication enhances partnership success significantly. They value long-term commitment over short-term gains.

| Characteristic | Description of Reliable Partner Hallmarks | Your Business Benefit |

|---|---|---|

| Reputation & Experience | Proven track record, positive customer feedback, years in international trade. | Reduces risk, leverages established expertise, builds confidence in product and service. |

| Certifications | ISO 9001, ISO 14001, FloorScore, CE Marking, ASTM, EN standards. | Ensures product compliance, market acceptance, and environmental/health safety. |

| Production Capacity | Sufficient production lines, modern machinery, ability to scale and customize. | Guarantees timely order fulfillment, supports growth, allows for unique product offerings. |

| Quality Control (QC) | Strict QC at raw material, in-process, and final inspection stages. | Consistent product quality, fewer defects, reduced returns, improved customer satisfaction. |

| Warranty & Support | Comprehensive warranty, responsive after-sales service, clear complaint resolution. | Minimizes post-purchase risk, protects your brand, fosters customer loyalty. |

| Supply Chain Efficiency | Strong logistics partners, real-time tracking, effective inventory management. | On-time delivery, reduced shipping costs, predictable lead times, efficient stock management. |

| Ethical Practices | Fair labor, environmental responsibility, use of recycled materials. | Appeals to eco-conscious consumers, enhances brand image, ensures sustainable sourcing. |

| Cultural Compatibility | Willingness to build "guanxi," open communication, respect for cultural norms. | Smoother negotiations, stronger relationships, better problem-solving, long-term stability. |

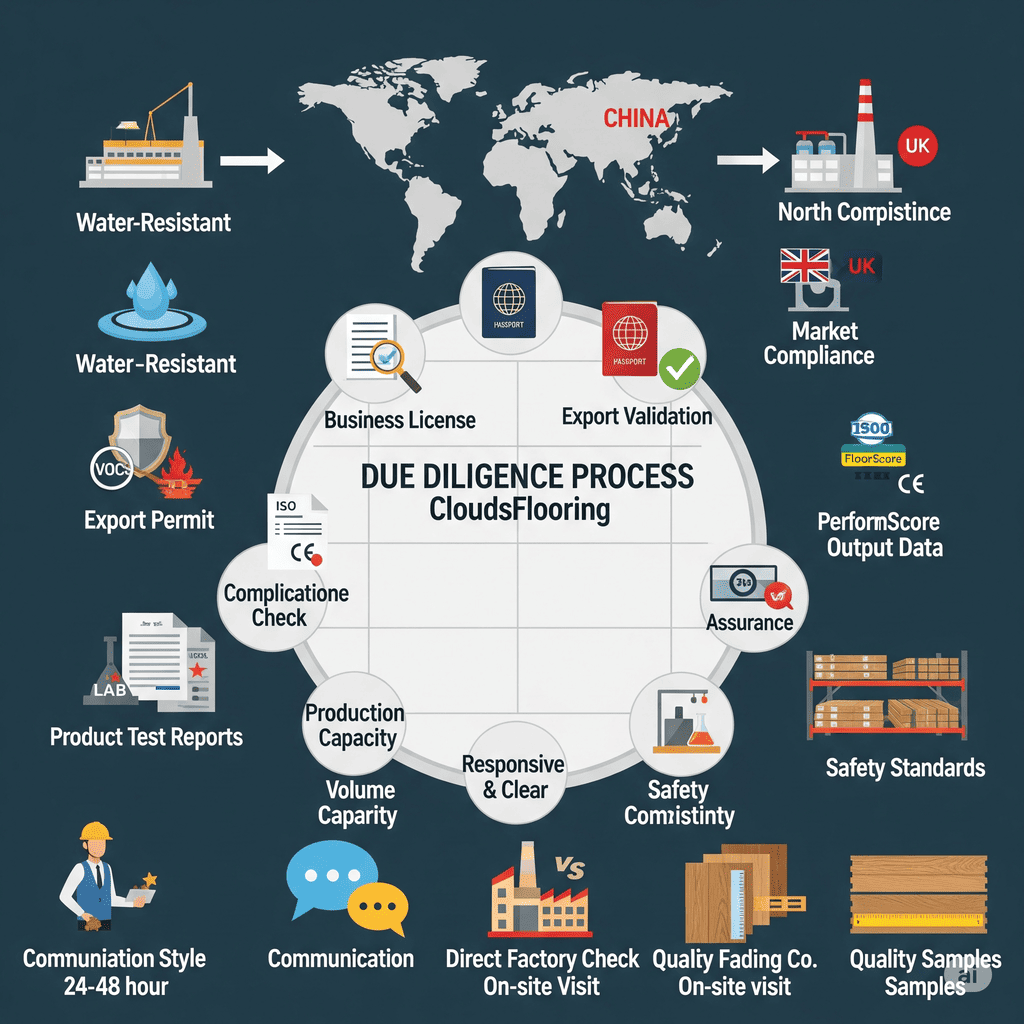

What crucial due diligence and document verification must be done before choosing a manufacturer?

Picking a manufacturer without checking can be risky. Many suppliers claim a lot, but facts prove otherwise. Verify documents to avoid big problems later.

Before choosing, verify business licenses, export permits, and quality certifications like ISO 9001 and CE. Check product test reports for VOCs, formaldehyde, and fire ratings, especially FloorScore for indoor air quality, to ensure compliance.

Before I even think about placing an order, I make sure to do thorough due diligence. It is crucial to verify every document a potential supplier provides. First, ask for their business license. This confirms they are a legally registered company in China. Check the registration date, legal name, business scope, and registered capital to ensure they align with their claims. You can often verify this through local business registries or by using third-party services.

Then, request their export permits1. Not all factories can export directly; some use trading companies. Confirming direct export capability is important for B2B wholesale as it often leads to more direct communication, potentially better pricing, and faster issue resolution.

Next, and very important for SPC flooring, are quality certifications. Request certificate numbers for ISO 9001 (quality management), ISO 14001 (environmental management), FloorScore (low VOC emissions), and CE Marking (EU compliance). Critically, verify their validity on the issuing body’s website (e.g., ISO, SCS Global) or by direct contact. Ensure certificates are current and not expired, as some suppliers may present outdated documents. My clients like Lori and Aiden always prioritize these.

I also insist on detailed product specifications and samples. Request full material composition (e.g., percentage of virgin/recycled PVC, limestone powder, calcium-zinc stabilizers), total thickness, and precise layer breakdown (e.g., 0.5mm wear layer, 4mm core). Always request samples from current production batches. Test these samples for dimensional accuracy, locking system functionality, and wear resistance to confirm they meet your expectations.

Furthermore, inquire deeply about their quality control processes. Understand their raw material sourcing – do they use virgin PVC for top quality, or recycled materials for eco-friendliness? Ask about their internal QC procedures, including inspection stages like raw material receiving, in-process checks (e.g., extrusion consistency, lamination adhesion, cutting precision), and final product testing. Request third-party testing reports for critical properties like VOCs, formaldehyde content (ensuring E0 or CARB P2 compliance), fire ratings, and slip resistance.

Finally, assess their production capacity and communication. Request data on their production lines and capacity to ensure they can meet your order volumes without delays. Test their responsiveness by sending detailed inquiries – a reliable manufacturer should respond within 24-48 hours with clear, proactive communication. Differentiate between a factory and a trading company by checking the business license scope, website focus (factory-specific vs. broad product range), and depth of technical knowledge. True factories like CloudsFlooring often invite on-site visits, while trading companies may deflect or make excuses.

| Document / Due Diligence | Specific Verification Points | Why It’s Crucial | Risk of Omission |

|---|---|---|---|

| Business License | Legal name, registration number, business scope (manufacturing vs. trading), registered capital, valid date. | Confirms legitimate operation and direct factory status. | Dealing with resellers, legal disputes, payment issues. |

| Export Permit | Validity, scope of export operations, consistency with business license. | Ensures legal international trade, avoids customs delays. | Shipments stuck at port, unforeseen costs. |

| ISO 90012/14001 | Certificate number, issuing body, validity date, scope. Verify online. | Validates quality/environmental management systems. | Inconsistent quality, environmental non-compliance. |

| FloorScore3/CE Marking | Product type, validity, matching supplier/brand name. Verify via SCS Global (FloorScore) or notified body. | Ensures product meets market-specific health/safety standards. | Product rejection, legal liabilities, poor indoor air quality. |

| Product Test Reports | Accredited lab name, test date, specific results (VOC, fire, slip, indentation), matching product. | Confirms performance and safety specifications. | Substandard products, customer complaints, safety hazards. |

| Production Capacity | Number of lines, daily output, utilization rates, backup plans. | Guarantees volume fulfillment, prevents delays. | Missed deadlines, production bottlenecks, lost sales. |

| Communication Style | Response time, clarity, proactivity, English proficiency. | Facilitates smooth operations, quick problem-solving. | Misunderstandings, delays, inefficient collaboration. |

| Factory vs. Trading Co. | Business license, factory address, number of employees, technical depth during discussions. | Ensures direct relationship, potentially better pricing and control. | Higher costs, less control over quality, communication layers. |

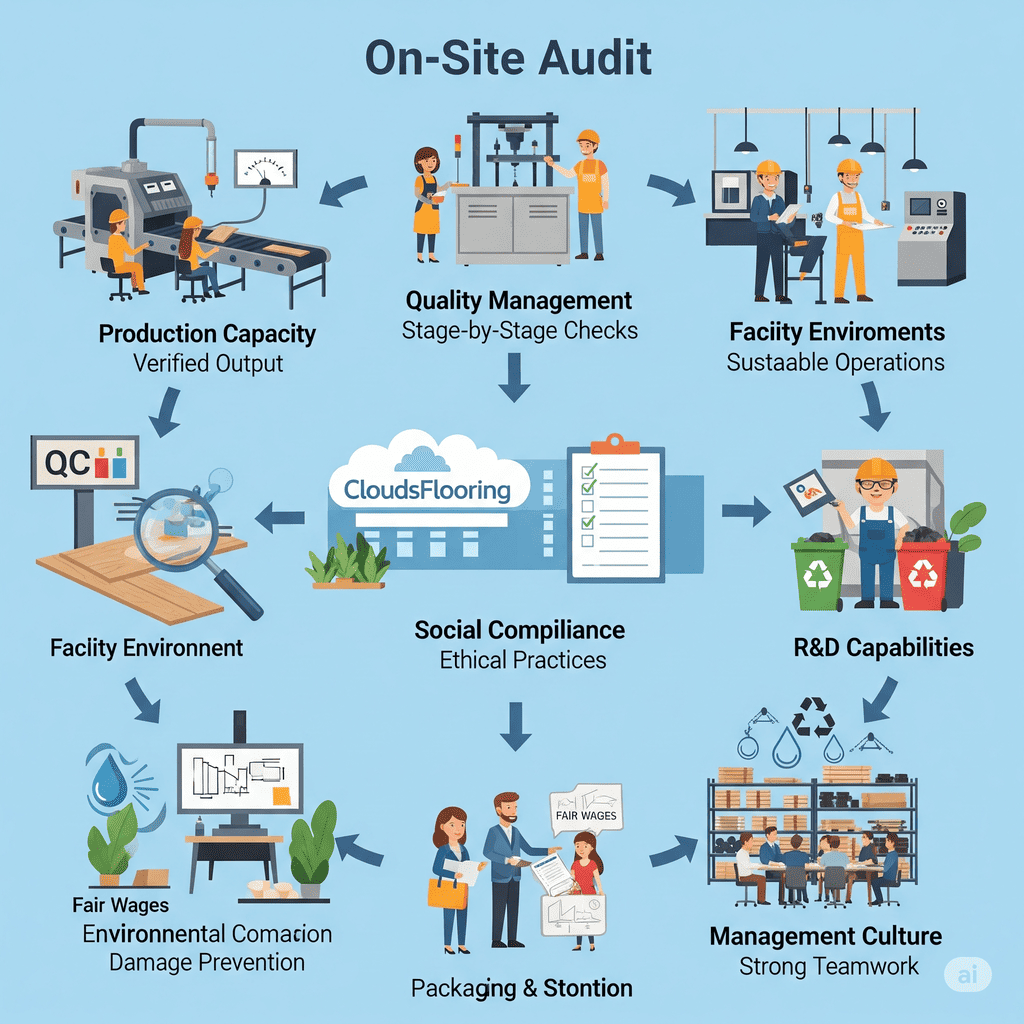

Why is an on-site factory audit non-negotiable for assessing a supplier’s true capabilities and compliance?

Trusting pictures and words can lead to bad surprises. What a factory shows online might not be real. An audit is the best way to see the truth.

An on-site factory audit is crucial to confirm production capabilities, quality control processes, and compliance standards. It lets you see operations firsthand, verifying certifications, raw material handling, and worker conditions to ensure consistent quality.

For me, an on-site factory audit1 is truly non-negotiable. It is one thing to see photos or read documents, but it is another to walk through the factory floor yourself. This is the only way to truly assess a supplier’s capabilities and compliance. While third-party audits (e.g., by SGS or Intertek) are valuable, an on-site visit by you or your team offers the most reliable assessment. It allows immediate clarification of concerns and strengthens the partnership.

During an audit, I specifically look for production capacity verification. I observe the machinery, workforce, and production lines. Are they modern and well-maintained? Can they handle your order volumes efficiently? This helps me gauge their actual capacity and efficiency. My CloudsFlooring factories, with 3 LVT and 2 SPC production lines, welcome such visits to showcase our operational strength.

I then conduct a thorough quality management assessment2. This involves reviewing their quality control processes at every stage: from how they inspect incoming raw materials (limestone, PVC, wear layer films), through in-process checks during extrusion, lamination, and cutting, right up to final product testing. I ensure they have a dedicated QC lab with the right equipment and trained personnel to perform essential tests like dimensional stability, wear resistance, and click system integrity. This helps prevent the quality differences that worry clients like Lori and Aiden.

Furthermore, a facility evaluation is critical. I check the factory’s overall organization, cleanliness, and safety standards. A well-organized and clean facility reflects professionalism and attention to detail in their operations. This includes proper storage of raw materials and finished goods, appropriate ventilation, and clear safety signage.

Social and environmental compliance is another key area. During an audit, I verify adherence to labor laws, such as working hours and fair wages. I also look for environmental regulations, like proper waste disposal methods for PVC scraps and water treatment. This is crucial for ethical sourcing and appeals to environmentally conscious consumers, aligning with certifications like ISO 14001.

Finally, an on-site visit is invaluable for relationship building. In-person interactions foster trust and stronger communication, especially important in Chinese business culture. It demonstrates your commitment and allows for direct, face-to-face discussions to clarify concerns and build a more personal connection, fostering "guanxi." This direct engagement helps avoid the inefficient communication that often troubles buyers.

| Audit Focus Area | Key Observation Points and Assessment Criteria | Insights Gained for Your Business |

|---|---|---|

| Production Capacity | Number, age, and condition of production lines; labor force size; daily output. | Confirmation of ability to meet order volumes and timelines; potential for future scaling. |

| Quality Management | Raw material inspection process; in-process QC checkpoints; final product testing equipment and procedures; QC staff training. | Assurance of consistent product quality; identification of potential defect sources. |

| Facility Environment | Cleanliness, organization, lighting, ventilation, pest control, material flow. | Reflects management professionalism, potential for contamination, and overall operational efficiency. |

| Social Compliance | Worker safety equipment, fire exits, working hours, dormitories (if any), child labor prevention. | Ethical sourcing verification, risk mitigation for labor disputes, brand reputation protection. |

| Environmental Compliance | Waste disposal methods (solid/liquid), recycling programs, air emissions controls, environmental permits. | Alignment with sustainability goals, compliance with international environmental regulations. |

| R&D Capabilities | Dedicated R&D department, design new products, customization capabilities. | Potential for innovation, ability to develop unique products for your private label. |

| Packaging & Storage | How finished goods are packed, stored, and protected from damage; warehouse organization. | Ensures products arrive undamaged, reflects care in handling final products. |

| Management Culture | Observation of leadership style, communication between staff and management, overall workplace atmosphere. | Insights into operational discipline and commitment to quality and service. |

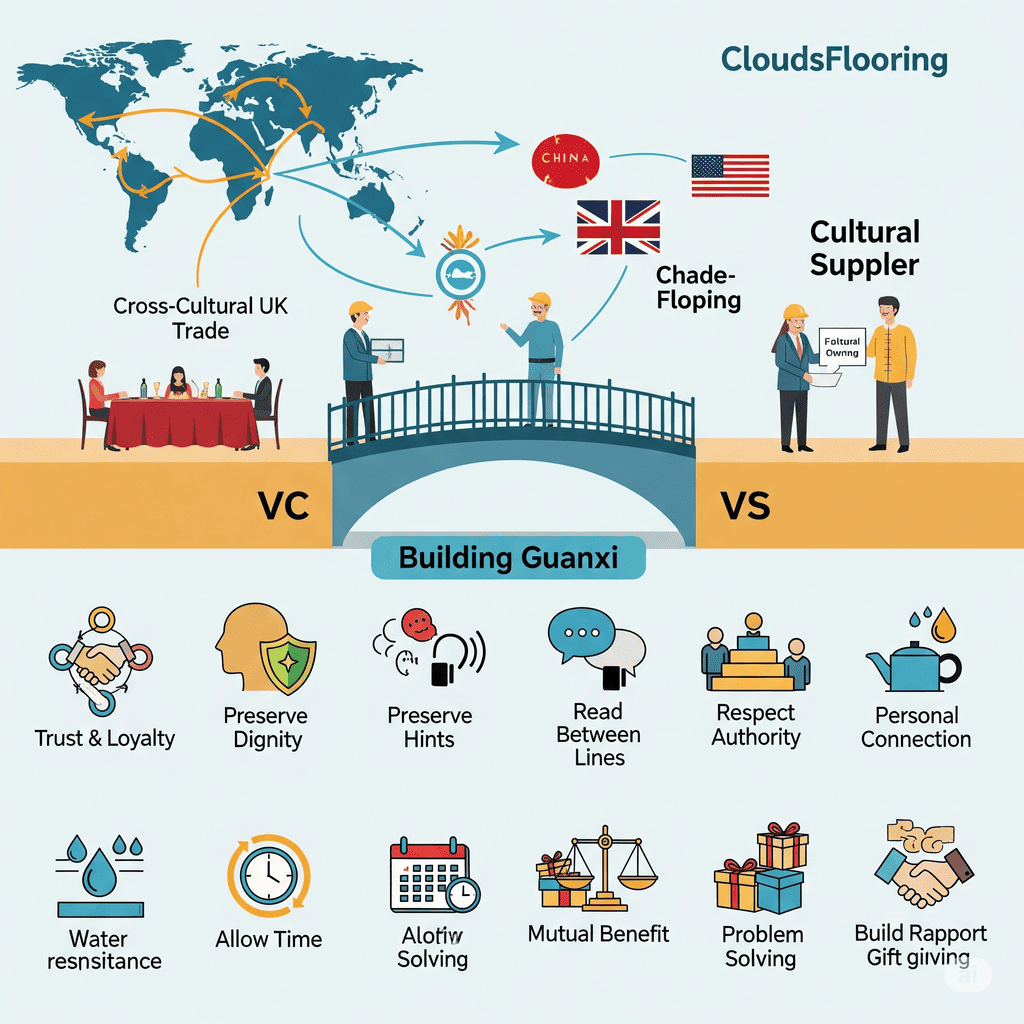

How can you navigate cultural differences in communication and negotiation to build "guanxi" (relationships)?

Communication gaps can make deals hard. Different cultures have different ways of talking. Understanding this is key to good partnerships.

Navigating cultural differences means patience, clear direct communication, and understanding the importance of ‘guanxi’ (relationships). Build trust by being respectful, consistent, and valuing long-term commitment.

One of the biggest lessons I have learned in international business, especially when dealing with buyers from North America and the UK, is the importance of understanding cultural differences. In China, building "guanxi," or strong personal relationships, is very important. This goes beyond just a business deal. It means trust, mutual respect, and a willingness to help each other over the long term. This foundation allows for greater flexibility and problem-solving, which is crucial for managing challenges like delayed shipments or quality issues.

To effectively navigate these differences, it is vital to understand Chinese business culture. Respect for hierarchy is fundamental; always address counterparts with their appropriate titles (e.g., Mr., Ms., Manager) and show deference to senior individuals. Avoid causing loss of "face" (mianzi), which refers to a person’s dignity, reputation, and respect. Public criticism or overly aggressive demands can cause a supplier to lose face, severely damaging the relationship. Instead, approach issues privately and collaboratively, allowing them to save face.

Adopt an understanding of indirect communication. Chinese communication can often be subtle or indirect, especially when conveying negative news or disagreement. Pay attention to non-verbal cues, tone of voice, and subtle language. Learning basic Mandarin phrases, even simple greetings, shows respect and effort, significantly enhancing trust and rapport. While I always use clear and simple English at CloudsFlooring to avoid misunderstandings, I encourage my team to recognize these nuances.

Be patient in negotiations. Decisions may require consensus from multiple levels within their organization, so allow sufficient time for discussions and avoid rushing the process. Demonstrating patience reflects respect for their decision-making process. Exchange modest gifts and host banquets; these are traditional ways to build rapport and demonstrate goodwill, strengthening personal connections.

Finally, emphasize reciprocity. Demonstrate mutual benefit through fair dealings and consistent reliability. By being a trustworthy partner who delivers on commitments, you encourage your supplier to reciprocate, fostering a strong and enduring partnership. This approach, centered on building genuine "guanxi," helps overcome inefficient communication that often troubles buyers and leads to more successful and resilient collaborations for your SPC flooring business.

| Cultural Aspect | Description and Nuance | How to Apply in Business Interactions | Benefit for Your Partnership |

|---|---|---|---|

| Guanxi | A network of influential relationships built on trust, loyalty, and reciprocity. | Invest time in building personal connections, be reliable, offer help, celebrate milestones, show long-term commitment. | Smoother negotiations, greater flexibility, quicker problem resolution, enhanced loyalty. |

| Mianzi/ Face | Reputation, dignity, and prestige; can be gained, lost, or given. | Avoid public criticism or direct confrontation; provide feedback privately; offer praise publicly; be humble. | Preserves respect, encourages cooperation, maintains open communication channels. |

| Indirect Communication | Often implied or hinted at, especially when conveying negative news or disagreement. | Listen carefully, ask clarifying questions, observe body language, read between the lines, reconfirm understanding. | Reduces misunderstandings, fosters trust through careful listening, avoids misinterpretations. |

| Hierarchy | Strong respect for authority, seniority, and established positions. | Address senior individuals first, respect decision-making structures, follow established protocols, avoid undermining authority. | Shows respect, ensures proper channels for communication, facilitates efficient decision-making. |

| Patience | Business relationships develop over time; decisions may not be rushed. | Be prepared for longer negotiation periods, avoid pushing for quick decisions, demonstrate consistent reliability. | Builds trust, allows for thorough consideration, leads to more robust agreements. |

| Reciprocity | The expectation of mutual benefit and returning favors or kindness. | Offer fair deals, be reliable, follow through on promises, reciprocate gestures of goodwill, offer support. | Strengthens mutual respect and commitment, encourages long-term cooperation. |

| Gift Giving | A common way to build rapport and show respect (modest and thoughtful). | Offer small, thoughtful gifts during visits; consider local customs; avoid overly expensive gifts. | Builds goodwill, fosters personal connection, signals respect for culture. |

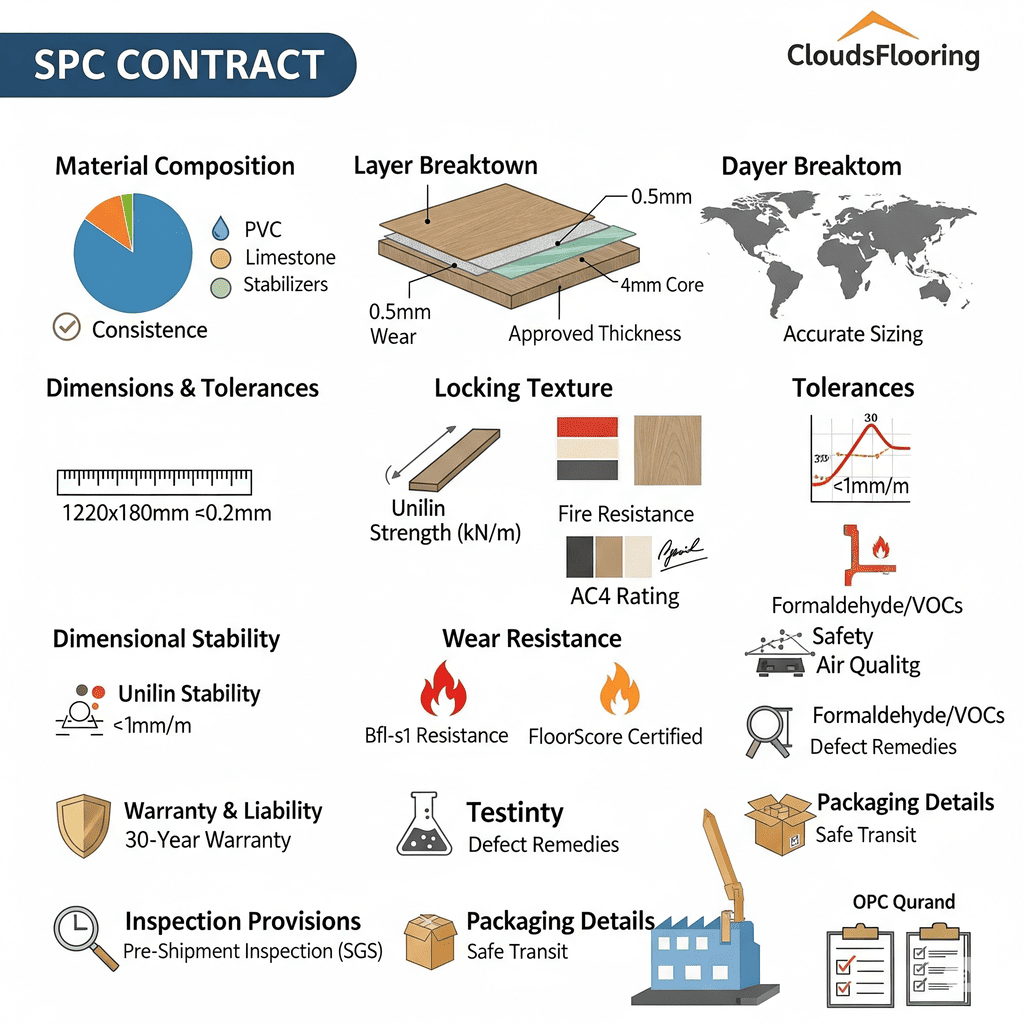

What detailed specifications and quality tolerances must be in your contract to guarantee product consistency?

Vague contracts lead to big problems. If details are not clear, you get inconsistent products. Your contract must define everything clearly.

Your contract must include detailed specifications like plank dimensions, thickness (e.g., 4-8mm), wear layer (e.g., 12mil or 20mil), and core density. Define quality tolerances for color variation, edge straightness, and click system performance to ensure consistency.

To guarantee product consistency, every detail must be in your contract. This is crucial for avoiding quality differences after receiving goods, a common complaint from clients like Lori. First, clearly state the product specifications. This includes the full material composition (e.g., percentage of virgin/recycled PVC, limestone powder, calcium-zinc stabilizers used in the core). Specify the total plank thickness (e.g., 5mm) and a detailed layer breakdown (e.g., 0.5mm wear layer, 0.1mm UV coating, 4mm core, 1.0mm IXPE/EVA backing).

Define the precise dimensions (length, width, square footage per box), providing exact measurements like 1220mm x 180mm with minimal tolerance (e.g., ±0.2mm). Clearly state the design, color, and texture details, cross-referencing with approved physical samples that both parties sign off on. The locking system type (e.g., Unilin, Valinge click-lock) and its performance standards (e.g., interlocking strength measured in kN/m) must also be specified.

Next, include precise quality tolerances1. For dimensional stability, specify the maximum allowable expansion/contraction (e.g., ±1mm per meter) under various temperature and humidity conditions. For color consistency, define acceptable variations across batches using a scientific Delta E value (e.g., <2.0 compared to master sample). Address surface quality, ensuring no visible scratches, dents, or bubbles. Specify performance metrics like wear resistance (e.g., AC4 rating), impact resistance (e.g., critical fall height), and slip resistance (e.g., R9 or specific COF).

Crucially, demand testing and certification2 requirements. Require valid test reports from accredited labs (e.g., ASTM, ISO standards) for each batch. Insist on compliance with certifications like FloorScore for indoor air quality and CE Marking for EU markets, ensuring these are provided with each shipment.

Finally, include inspection provisions and warranty/liability clauses. Specify the right to conduct pre-shipment inspections by third-party agencies (e.g., SGS, Intertek) at the factory, with acceptance criteria defined. Clearly define warranty terms (e.g., 30-year limited residential, 10-year commercial) and outline liability for non-conforming products, including remedies like replacement, discount, or return. These clauses ensure products meet your standards consistently, protecting your business and reputation.

| Contract Clause Area | Specific Details to Include | Why It’s Indispensable |

|---|---|---|

| Material Composition | Percentage of virgin/recycled PVC, limestone powder, stabilizers, additives. | Ensures product purity, durability, and health/environmental compliance (e.g., phthalate-free). |

| Layer Breakdown | Total thickness (e.g., 5mm), specific thickness of wear layer (0.5mm), decorative film, core, and backing. | Defines product quality, wear performance, and contributes to dimensional stability. |

| Dimensions & Tolerances | Precise length, width, and thickness (e.g., 1220x180mm ±0.2mm), square footage per box. | Guarantees ease of installation, consistent appearance, and accurate quantity. |

| Design/Color/Texture | PMS/RAL codes, reference to approved physical samples, specific texture (EIR, wood grain, stone). | Ensures visual consistency across orders and aligns with market aesthetic demands. |

| Locking System | Type (Unilin, Valinge), detailed specifications for click profile, interlocking strength (kN/m). | Critical for ease of installation, preventing gapping, and long-term floor integrity. |

| Dimensional Stability | Max allowable expansion/contraction under specified temperature/humidity (e.g., <0.08%). | Prevents warping, gapping, or buckling after installation, crucial for floor longevity. |

| Wear Resistance | AC rating (AC3, AC4, AC5), or specific abrasion cycles (e.g., EN 438-2.6). | Determines suitability for residential vs. commercial use, directly impacts product lifespan. |

| Fire Resistance | Specific Class (e.g., Bfl-s1 for EU, ASTM E648 Class A for US). | Essential safety feature, required by building codes for many applications. |

| Formaldehyde/VOCs | E0, CARB P2 compliance, FloorScore certification details. | Guarantees healthy indoor air quality, critical for health-conscious markets. |

| Warranty & Liability | Detailed terms (duration, coverage, exclusions), procedures for claims, remedies for defects. | Protects your business from defective products, outlines supplier’s responsibility, builds customer trust. |

| Inspection Provisions | Right to conduct pre-shipment inspection (PSI) by third-party (e.g., SGS), AQL standards. | Ensures product quality before shipping, minimizes risk of receiving non-conforming goods. |

| Packaging Details | Carton size, weight, labeling requirements (logo, batch number, production date). | Ensures safe transit, clear identification, and compliance with your branding. |

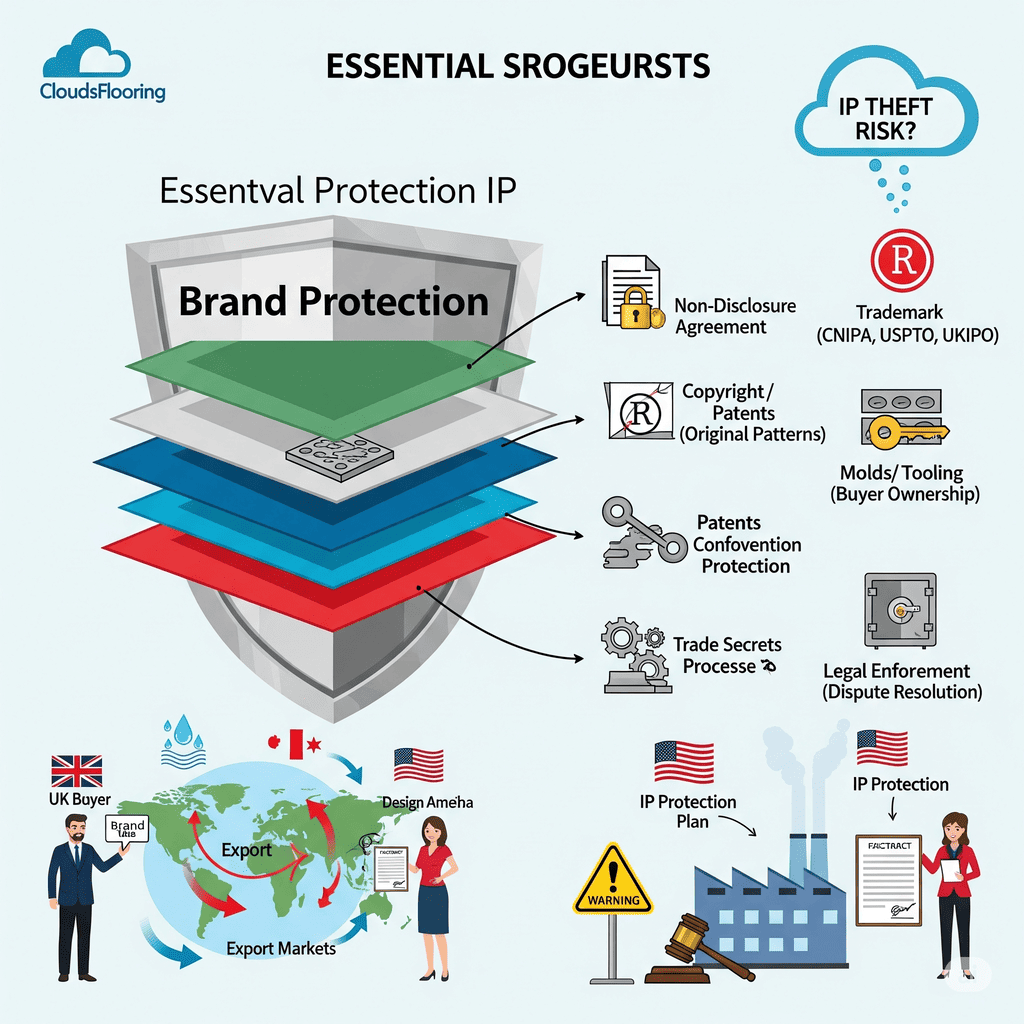

If creating a private label, what safeguards are needed to protect your brand’s intellectual property?

Your brand is valuable. If you don’t protect it, others can copy it. Safeguarding your private label is critical for your business.

To protect your private label, sign a Non-Disclosure Agreement (NDA) and a Manufacturing Agreement with IP clauses. Register your trademarks in China and your target markets. Ensure clear ownership of molds and designs.

When you create a private label for your SPC flooring, like many of my clients in the UK and North America do, protecting your brand’s intellectual property (IP) is paramount. Your designs, your logo, your brand name, and any unique product features are valuable assets. Failure to protect them can lead to counterfeiting, unauthorized sales by competitors (including your own manufacturer), and severe damage to your brand reputation and market share.

First, I always recommend signing a robust Non-Disclosure Agreement (NDA)1 with your supplier. This legally binds them to keep your designs, specifications, custom patterns, and all other sensitive business information confidential. This document should be in place and signed before sharing any proprietary product details or design files.

Second, your main manufacturing agreement must include strong IP clauses. These clauses should explicitly state who owns the designs, any custom molds or embossing plates created specifically for your product (e.g., unique wood grain textures or stone patterns), and all branding elements (logos, packaging designs, installation guides). It should also contain a clear prohibition on the factory from producing, selling, or otherwise using your specific private-label design or branding for anyone else. This is vital because if the factory owns the mold or pattern, they could potentially produce for others, directly competing with you. It is often best to explicitly state that you, the buyer, own any custom tooling or molds and that they should be returned or destroyed upon termination of the agreement.

Third, a critical step is trademark registration2. Register your brand name, logo, and any unique product marks with the intellectual property offices in China (CNIPA – China National Intellectual Property Administration), where the product is manufactured. This is crucial as it gives you legal standing to prevent counterfeiting or unauthorized use within the country of origin. Additionally, register your trademarks in your main export markets, such as the US (USPTO – United States Patent and Trademark Office) and the UK, to protect your brand where you sell.

Consider copyright protection3 for original designs or unique artistic elements in your flooring patterns or packaging. If your flooring incorporates a novel design or technological feature, explore patent protection. While less common for standard SPC flooring, it can provide significant competitive advantage. Regularly conduct quality control checks and legal monitoring. This involves actively searching for unauthorized use of your IP online and in the market and taking swift legal action if infringement occurs. At CloudsFlooring, we understand the immense value of our clients’ brands. We are committed to safeguarding your intellectual property and have clear procedures in place to protect your private label designs and logos, ensuring your unique style remains yours and preventing unfair competition.

| IP Type | Safeguard Measure | Purpose and Benefit |

|---|---|---|

| Confidential Info | Non-Disclosure Agreement (NDA) signed with the manufacturer and any third parties. | Legally protects all sensitive product specs, designs, and business strategies from unauthorized disclosure. |

| Brand Name/Logo | Trademark Registration in China (CNIPA) and all target export markets (e.g., USPTO, UKIPO). | Grants legal exclusive rights to use your brand name and logo, enabling you to prevent counterfeiting and infringement. |

| Unique Product Designs | Copyright Protection for specific patterns/artwork; Design Patents for novel ornamental designs; IP clauses in Manufacturing Agreement. | Prevents replication of your unique flooring patterns or visual designs; legally forbids the manufacturer from producing your designs for others. |

| Molds/Tooling | Contractual Clause specifying buyer ownership of custom molds/tooling; arrangement for storage/return/destruction. | Ensures proprietary tooling used only for your products; prevents unauthorized production of your designs. |

| Technological Features | Utility Patents for functional innovations (if applicable). | Protects any unique technical improvements or manufacturing processes in your SPC flooring. |

| Trade Secrets | Robust confidentiality clauses in all agreements; internal factory security measures. | Safeguards proprietary manufacturing processes, material formulations, or unique treatment methods. |

| Legal Enforcement | Clauses for breach of contract, specified dispute resolution mechanisms, active legal monitoring. | Provides legal recourse if IP is violated, allowing for injunctions, damages, or seizure of infringing goods. |

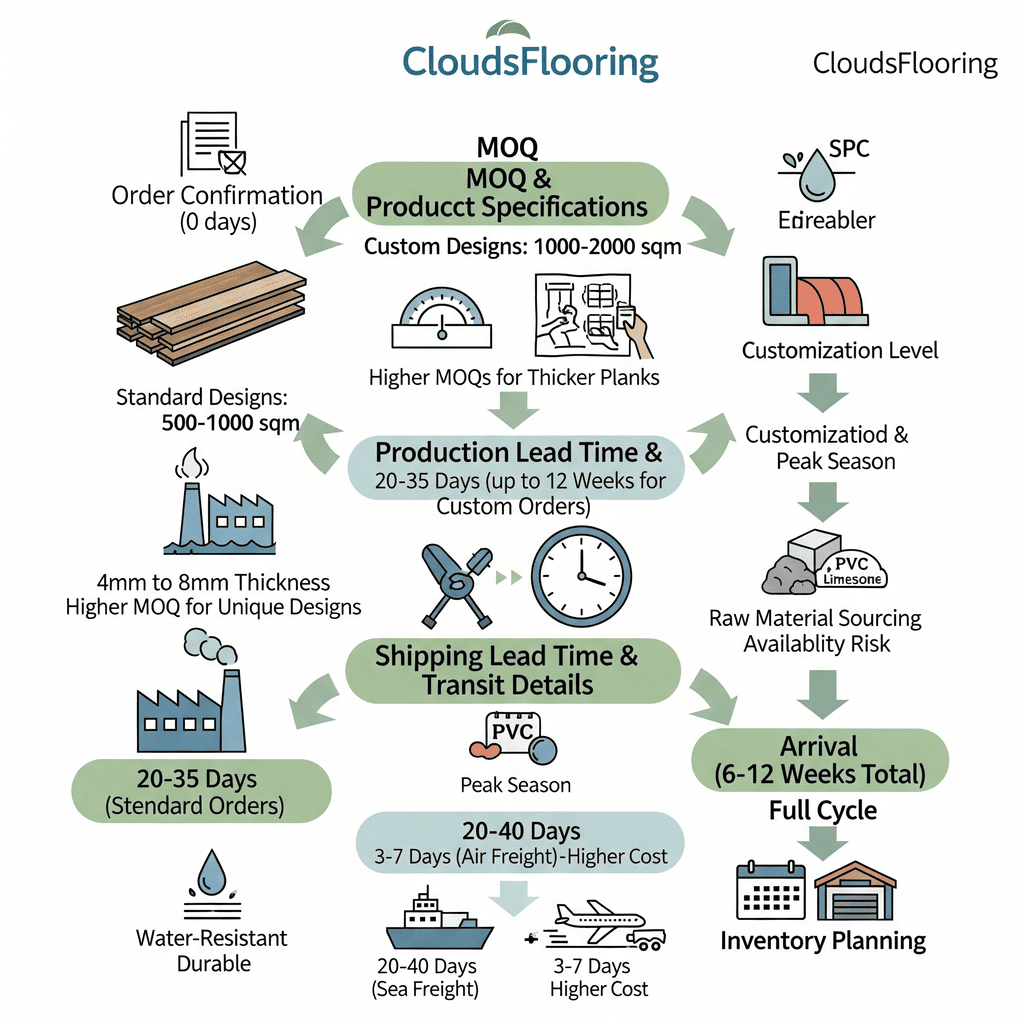

What are the typical minimum order quantities (MOQs) and lead times when sourcing directly from a factory in China?

Planning your orders needs clear timing. Unknown MOQs and lead times can mess up your stock. Know these numbers before you commit.

Typical SPC flooring MOQs from Chinese factories are around 500-1000 square meters per color/design, while lead times are usually 20-35 days after deposit and design confirmation, depending on order size.

Understanding typical minimum order quantities (MOQs) and lead times is vital for inventory planning and cash flow management. This insight helps you avoid missed selling seasons, a common pain point for buyers like Aiden and Lori. For SPC flooring, a common MOQ for a single color or design at factories like CloudsFlooring is around 500 to 1000 square meters. However, this can vary significantly based on several factors, including plank thickness, wear layer, and whether the design is standard or custom. For instance, a very specific, rare style or a completely custom design might require a higher MOQ, sometimes needing a full container (around 2500-3000 sqm for 4mm or 5mm SPC, and about 2000-2500 sqm for 6mm or 8mm SPC).

The MOQ is often intrinsically linked to the factory’s production run efficiency and raw material procurement. Factories need to run a certain minimum volume to make a production line profitable and to justify purchasing raw materials like limestone powder, PVC resins, decorative films, and wear layer films in bulk from their suppliers. If your order is below the standard MOQ, some factories might still accept it, but typically with a higher unit price or a small order surcharge to compensate for the lower efficiency.

Lead times also vary. The overall lead time comprises two main components: production time and shipping time. Once you confirm your order and make the initial deposit, the production lead time1 usually takes about 20 to 35 days for standard orders. For custom designs or larger volumes, it can extend to 4-8 weeks, and up to 12 weeks for complex custom projects. This depends on the factory’s current order queue, the complexity of your order, and raw material availability. For instance, at CloudsFlooring, with our 3 LVT and 2 SPC production lines, we manage various order sizes and optimize our schedules for efficiency.

After production, you need to factor in shipping time. For North America or the United Kingdom, sea freight can add another 20-40 days. Air freight is much faster (3-7 days) but significantly more expensive, usually only viable for urgent, small orders or samples. Therefore, the total lead time for international orders typically ranges from 6-12 weeks for sea freight, from order confirmation to arrival at your destination port. It is crucial to get a precise timeline from your supplier based on your specific order before committing, to effectively manage your inventory and sales cycles.

| Factor | Typical Range / Details | Impact on Your Business |

|---|---|---|

| Minimum Order Quantity (MOQ)2 | Standard: 500-1000 sqm/color/design. Custom: 1000-2000 sqm. | Influences upfront capital investment, inventory holding costs, and storage space requirements. |

| Plank Thickness (mm) | Affects MOQ: Thicker planks (e.g., 8mm) generally have higher MOQs due to material usage. | Higher thickness often means higher MOQs and slightly longer production time. |

| Customization Level | Standard colors/designs vs. unique patterns, specific wear layer thicknesses. | Customization usually increases MOQ and extends production lead times significantly. |

| Production Lead Time | Standard Orders: 20-35 days. Custom Designs/Large Volumes: 4-8 weeks, up to 12 weeks. | Directly impacts how quickly you can replenish stock and respond to market demand. |

| Shipping Lead Time | Sea Freight: 20-40 days (e.g., China to North America/UK). Air Freight: 3-7 days (much higher cost). | Determines the total time from order to delivery; critical for seasonal planning. |

| Factory Workload | Higher demand periods (e.g., pre-Chinese New Year) can extend lead times. | Important to inquire about current factory capacity and potential delays during peak seasons. |

| Raw Material Sourcing | Availability of specific raw materials (PVC, limestone, films). | Shortages can delay production. Suppliers with diverse sourcing mitigate this. |

| Total Lead Time | Typical Total: 6-12 weeks (Production + Sea Freight). | Crucial for overall supply chain planning and setting realistic delivery expectations for your customers. |

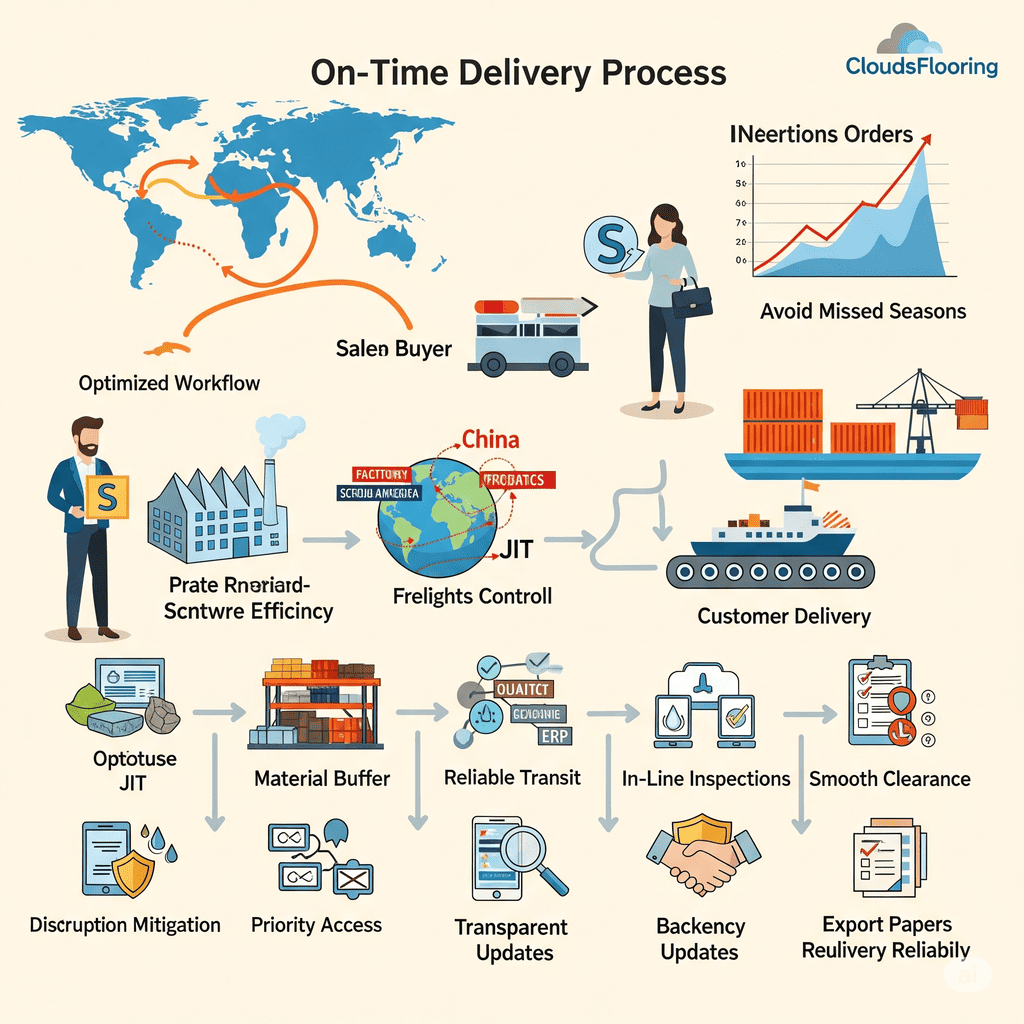

How do top-tier suppliers manage their supply chain to ensure on-time delivery for international orders?

Late shipments cost money and missed sales. You need on-time delivery, always. A good supplier plans every step carefully.

Top-tier suppliers manage their supply chain through robust inventory control, strong logistics partnerships, and transparent communication. They use production planning software, track shipments closely, and have contingency plans for delays.

On-time delivery is paramount for international orders. Delayed shipments can mean missed selling seasons, which is a big pain point for buyers like Aiden and Lori. Top-tier suppliers like CloudsFlooring manage their supply chain meticulously. First, they implement advanced production planning1 systems. This means using sophisticated scheduling software to optimize production lines. They create detailed schedules that account for order size, complexity, and available resources, ensuring efficient flow from material cutting to pressing, lamination, and finishing. This proactive planning minimizes bottlenecks and idle time.

Second, they employ robust inventory management2. This involves maintaining strategic stocks of key raw materials (limestone, PVC resins, decorative films, wear layers) while also utilizing just-in-time (JIT) principles for certain components to reduce carrying costs. By carefully tracking raw material availability and consumption, they avoid shortages that could halt production. This proactive inventory control helps ensure a steady supply for your SPC flooring.

Third, they forge strong logistics partnerships3. Top-tier suppliers work with multiple reputable freight forwarders and logistics companies. These partners have extensive experience in international shipping, customs clearance for various countries (like the US, UK, and Middle East), and diverse shipping routes. This allows for flexibility and ensures they can choose the most efficient and reliable transport options. They provide real-time tracking updates, so I know exactly where my clients’ shipments are, from the factory to the destination port.

Fourth, they integrate comprehensive quality control throughout their supply chain. This is not just a final inspection; it includes continuous quality checks at every stage of production, from raw material inspection to in-process checks and pre-shipment inspections. By catching potential defects early, they avoid the need for costly reworks or product rejection at the destination, which could cause significant delays.

Fifth, transparent communication is a hallmark. Top suppliers provide regular order updates, often through integrated ERP (Enterprise Resource Planning) systems or dedicated customer service channels. This includes notifying clients of production milestones, potential issues, and shipping progress. This proactive approach helps manage expectations and allows clients to plan accordingly.

Finally, they practice comprehensive risk management. Top suppliers have contingency plans for unforeseen disruptions such as material shortages, port congestion, or unexpected factory shutdowns (e.g., power outages or machinery breakdown). This might involve having backup suppliers, alternative shipping routes, or expedited production options to mitigate impacts and ensure continuity of supply. This foresight truly sets them apart and helps ensure your products arrive on time, supporting your goal of maintaining consistent inventory and meeting customer demand.

| Supply Chain Element | Top-Tier Supplier Approach | Benefit for On-Time Delivery |

|---|---|---|

| Production Planning | Advanced scheduling software, optimized line utilization, detailed workflow management. | Maximizes efficiency, minimizes bottlenecks, provides accurate production completion dates. |

| Inventory Management | Strategic raw material buffer stocks, just-in-time delivery for certain components. | Ensures continuous production flow, prevents material shortages, reduces delays from procurement. |

| Logistics Partnerships | Multiple reputable freight forwarders, global network, strong relationships with shipping lines. | Offers flexible shipping options, competitive rates, and reliable transit times, even during peak seasons. |

| Quality Control (QC) | In-line QC, pre-shipment inspections (PSI), integrated QC checkpoints throughout production. | Reduces rework, prevents defective products from being shipped, avoids customs holds due to non-compliance. |

| Communication & Tracking | ERP systems for real-time updates, dedicated logistics contact, proactive problem notification. | Provides full transparency on order status, enables proactive planning, and quick issue resolution. |

| Risk Management | Contingency plans for material shortages, natural disasters, port congestion, political changes. | Mitigates impact of unforeseen disruptions, ensures continuity of supply, protects delivery schedules. |

| Supplier Relationships | Long-term contracts with key raw material suppliers, strong "guanxi" with all partners. | Ensures priority access to materials, fosters collaboration for problem-solving, enhances reliability. |

| Documentation & Compliance | Dedicated team for export documentation, adherence to international trade regulations. | Streamlines customs clearance, prevents delays due to paperwork errors or non-compliance. |

Once shipments arrive, how can you effectively verify that quality remains consistent from batch to batch?

Goods arrive, but are they what you ordered? Quality can change, even with a good supplier. You must check every time.

Verify consistency by conducting thorough incoming inspections of each batch. Check color match against samples, measure dimensions, and test click system performance. Use independent third-party inspections if possible.

Even with a top-tier supplier, verifying quality consistency for each incoming shipment is crucial. This proactive step helps catch any potential quality differences that might have slipped through, a common concern for Lori. The first step is to perform a thorough incoming inspection1. Do not just open one box. Randomly select boxes from different pallets or parts of the container using a statistical sampling method like AQL (Acceptable Quality Limit). This ensures a representative sample that truly reflects the batch’s quality.

Visually inspect for defects. Look for scratches, chips, delamination, warping, bowing, or surface imperfections. Compare the color, pattern, and gloss level against the approved master sample from your initial order. This is very important as slight color shifts can occur between batches, which can be noticeable when installed.

Then, conduct quality testing on your premises. Accurately measure the dimensions of the planks – length, width, and overall thickness (e.g., 4mm, 5mm, 6mm, or 8mm) – using precision calipers to ensure they meet your specified tolerances (e.g., ±0.1mm). Inconsistent dimensions can lead to difficult installations and unsightly gaps. Check the click system: take several planks and try to lock them together. Do they join easily and securely? Are there any gaps or loose connections? This is a critical functional test for SPC flooring, which prides itself on easy installation. You might also perform basic wear resistance or impact resistance tests if you have the equipment, or send samples to a local lab for more detailed analysis.

Furthermore, always conduct a documentation review. Verify that all inspection reports, certificates of origin, packing lists, and any required certifications (like FloorScore or CE marking) match your order details and the physical goods. This ensures compliance and traceability.

Beyond your internal checks, consider pre-shipment inspection2 (PSI) by hiring a third-party inspection agency (e.g., SGS, Intertek) to verify products at the factory before shipment. This provides an unbiased report and identifies issues before they even leave China. Also, gather customer feedback from installers or end-users as soon as possible. Their real-world experience can quickly highlight any quality issues that might only become apparent during or after installation. Finally, perform regular audits of your manufacturer’s QC processes, as discussed earlier. This holistic approach ensures consistent quality across all batches, protecting your brand and customer satisfaction.

| Verification Method | What to Check / How to Do It | Why It’s Essential | Frequency / Best Practice |

|---|---|---|---|

| Incoming Visual Insp. | Randomly select boxes/planks (AQL sampling). Check for surface defects (scratches, dents), delamination, warping. | Catches visible flaws, ensures aesthetic quality meets standards. | Every incoming shipment. |

| Color/Pattern Match | Compare against master approved sample or previous batch sample under consistent lighting. | Ensures visual consistency across orders and avoids noticeable color shifts. | Every incoming shipment. |

| Dimensional Accuracy | Use calipers to measure length, width, and thickness of multiple planks. | Guarantees ease of installation, tight seams, and consistency of coverage. | Every incoming shipment. |

| Click System Function | Manually click several planks together; check for easy assembly, secure lock, no gapping. | Confirms proper function of the primary installation method, prevents callbacks. | Every incoming shipment. |

| Documentation Review | Verify packing lists, QC reports, certificates (FloorScore, CE), Bill of Lading match goods. | Ensures compliance, traceability, and proper product labeling. | Every incoming shipment. |

| Third-Party PSI (Pre-Shipment Inspection) | Hire an independent firm to inspect goods at the factory before shipment. | Catches major issues before products leave the factory, reduces risk of costly returns. | Highly recommended for first orders and large/critical shipments. |

| Performance Testing | Send samples to local lab for wear layer, indentation, slip resistance tests (if not done by factory). | Independent verification of critical performance properties. | Periodically, or if there are concerns about consistency. |

| Customer Feedback Loop | Actively solicit feedback from installers and end-users about product performance. | Identifies real-world issues, helps pinpoint recurring problems. | Ongoing process. |

| Reference Samples | Keep a labeled sample from each received batch for future comparison. | Provides a physical benchmark for future incoming quality checks. | For every unique batch received. |

What key performance metrics should you continuously track to maintain a successful long-term supplier partnership?

Good suppliers are partners for life. But you need to know if they are still performing. Tracking their work keeps them sharp.

Continuously track key performance metrics like on-time delivery rates, quality defect rates, communication response times, and pricing consistency. Regular reviews ensure the partnership remains beneficial and high-performing.

![]()

To maintain a successful, long-term supplier partnership for your SPC flooring business, it is not enough to just place orders. You need to continuously track key performance metrics. This ensures the partnership remains mutually beneficial and high-performing, addressing concerns like delayed deliveries or inconsistent quality, which can directly impact your profit margins and brand reputation.

First, track the On-Time Delivery Rate1. This is the percentage of your orders that arrive by the agreed-upon date. My clients, like Aiden and Lori, need reliable delivery to avoid missed selling seasons. This metric is fundamental for your own inventory management and sales predictability.

Second, monitor the Quality Defect Rate2. This is the percentage of products in a shipment that have defects or do not meet your quality standards. A low defect rate shows consistent quality, which is vital for any flooring business and customer satisfaction. It directly reduces costly returns, rework expenses, and potential damage to your brand.

Third, evaluate Lead Time. This is the average time from when you place an order to when it is delivered. Consistent and predictable lead times allow for better inventory planning and sales forecasting. Fourth, track Order Accuracy. This refers to the percentage of orders that match your specifications perfectly, including correct quantity, color, thickness, and packaging. Inaccurate orders create additional work and delays.

Fifth, assess Communication Response Time3. How quickly does your supplier respond to your emails or calls, especially when issues arise? Efficient communication is critical for resolving issues and managing expectations, particularly for international dealings across time zones. Sixth, monitor Cost Stability or pricing consistency. While raw material costs can fluctuate, a good supplier will manage this and communicate changes transparently, allowing you to maintain competitive pricing for your SPC flooring.

Additionally, consider Inventory Turnover related to the supplier’s efficiency – how quickly can they produce and ship specific styles to meet your demand? Track Customer Satisfaction relating to the product quality itself; direct feedback from installers and end-users is invaluable. Monitor Supplier Compliance to all contractual terms and regulatory requirements. Finally, for a long-term vision, track Sustainability Metrics, if applicable, such as their use of recycled materials or energy consumption, aligning with your company’s values. At CloudsFlooring, we value transparency and proactive communication. We encourage our partners to track these metrics because it helps us both grow stronger together. Regular reviews of these metrics, perhaps quarterly or semi-annually, keep the partnership healthy and aligned with your business goals, ensuring continued access to high-quality SPC flooring.

| Metric | Description and Calculation | Ideal Target | Why It’s Crucial for Your Business |

|---|---|---|---|

| On-Time Delivery Rate | (Number of On-Time Deliveries / Total Deliveries) x 100% | 95%+ | Critical for inventory planning, avoiding stockouts, meeting customer commitments, and maximizing sales during peak seasons. |

| Quality Defect Rate | (Number of Defective Units / Total Units Received) x 100% | <1% | Directly impacts customer satisfaction, return costs, rework expenses, and your brand’s reputation for quality SPC. |

| Lead Time | Average days from order confirmation to goods ready for shipment (or arrival at destination). | Consistent, agreed-upon. | Essential for inventory management, sales forecasting, and avoiding missed opportunities. |

| Order Accuracy | (Number of Accurate Orders / Total Orders) x 100% | 99%+ | Ensures you receive exactly what you ordered, minimizing logistical errors and unnecessary costs. |

| Communication Response Time | Average hours/days from inquiry to first meaningful response. | < 24 hours | Facilitates efficient problem resolution, quick decision-making, and smooth project timelines, especially for B2B wholesale. |

| Pricing Consistency | Variance in unit cost over a period, after accounting for agreed-upon adjustments. | Low variance | Facilitates accurate budgeting, stable profit margins, and ability to offer consistent pricing to your customers. |

| Supplier Compliance | Adherence to all contractual terms, quality standards, and regulatory requirements. | 100% | Ensures legal compliance, avoids fines or product recalls, protects your business reputation and market access. |

| Customer Satisfaction (Product) | Direct feedback (surveys, reviews) on the quality and performance of the received product. | High | Directly reflects product reliability, builds loyalty, and drives repeat business and referrals. |

| Problem Resolution Effectiveness | Average time and satisfaction level in resolving issues or complaints. | Fast & High | Minimizes disruption, preserves trust, and demonstrates the supplier’s commitment to the partnership. |

| Sustainability Metrics | Use of recycled content, energy consumption, waste management, certifications. | Improving | Aligns with eco-conscious market trends, enhances brand image, and ensures long-term ethical sourcing. |

Conclusion

Starting a successful SPC flooring business hinges on selecting a reliable factory partner, conducting thorough due diligence, and maintaining strong relationships, particularly with Chinese manufacturers. Detailed contracts, IP protection, and consistent quality verification ensure product reliability, while tracking performance metrics sustains long-term partnerships. By addressing these factors, your SPC flooring business can thrive in a competitive market.

The above data is for reference only.

-

Understanding this metric is crucial for maintaining inventory and meeting customer demands effectively. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring this will help you grasp how quality impacts customer satisfaction and brand reputation. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

This metric is vital for resolving issues quickly and maintaining smooth operations in your business. ↩ ↩ ↩ ↩