Choosing the right flooring for your projects can be tough, balancing easy installation with long-term performance. Many ask if self-adhesive vinyl flooring really meets professional standards. Does it stand up to real-world demands, or is it just for quick DIY fixes?

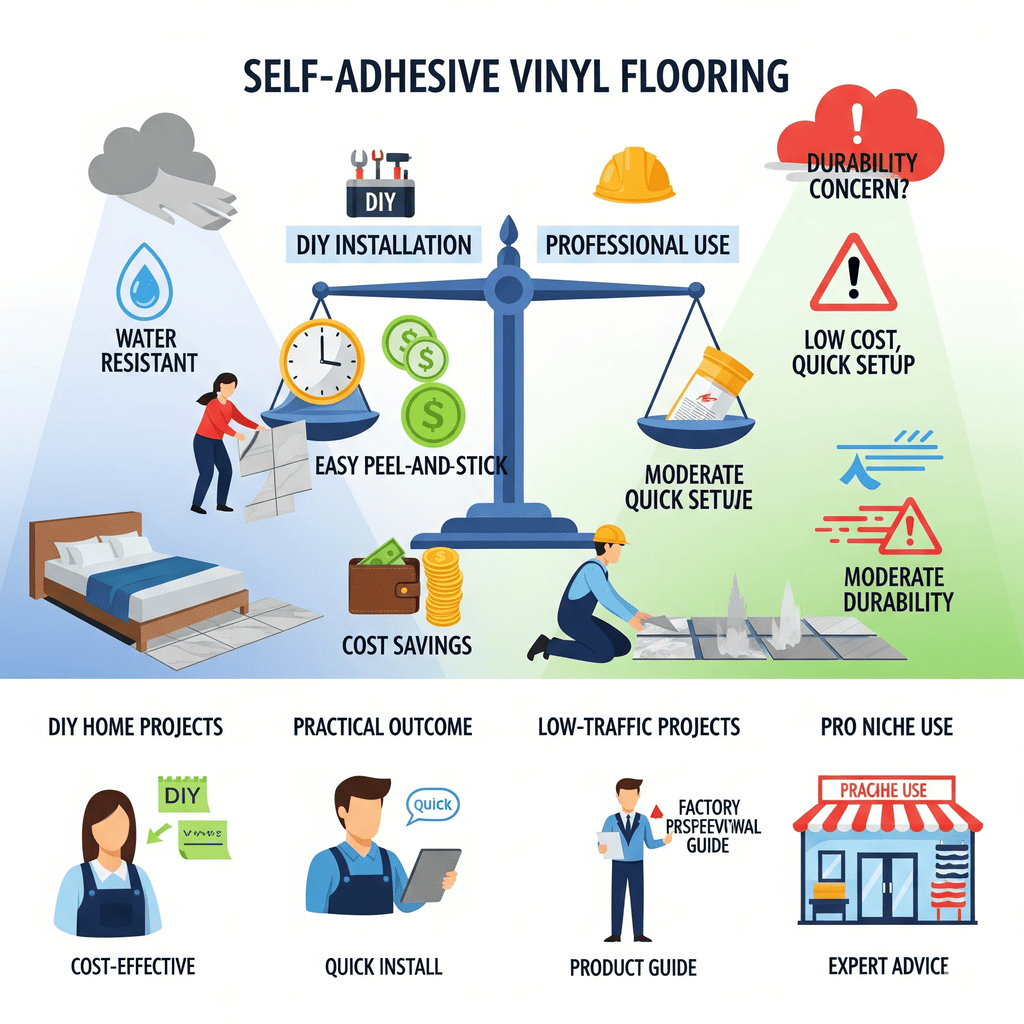

Self-adhesive vinyl flooring is primarily designed for DIY, but professionals may use it for specific, low-traffic projects where quick installation and cost savings are key. Its durability is moderate, often limited by adhesive wear and a thin wear layer, making it less suitable for high-traffic or long-term commercial use.

I often talk with my clients about different flooring options. They want solutions that perform well and offer good value. Understanding the true capabilities of self-adhesive vinyl flooring helps make smart business decisions. It is important to know where it fits and where other options, like our LVT or SPC, are a better choice.

Is Self-Adhesive flooring viable for professionals, or is it best for DIY installation?

Is self-adhesive vinyl flooring1 only for small home projects? Many think it lacks the strength for serious use. Let’s explore if it has a place in professional applications, or if it is truly just for DIY.

Self-adhesive vinyl flooring is mainly designed for DIY installation, offering a simple peel-and-stick method. However, professionals can find it viable for specific, low-traffic projects. This is true when quick installation and cost savings are more important than long-term, heavy-duty performance.

When I speak with large company buyers, they often look for flooring that can withstand heavy use. Self-adhesive flooring’s primary advantage is its ease of installation. This makes it attractive for certain situations. It is ideal for short-term solutions or areas like kids’ rooms, guest bedrooms, or low-traffic spaces where budget is a concern. For instance, a retail store needing a quick refresh before a major sale might consider it. Or, a residential developer looking for an affordable, fast solution for a low-budget rental property could use it. It can even be installed over existing flooring if it is level, which reduces labor costs and time.

DIY Focus and Professional Niche

The peel-and-stick nature means installation is very fast. It does not require special tools or professional skills. This saves labor costs and reduces project time significantly. I have seen projects completed in record time using this method. For these reasons, it is commonly used in residential settings, especially for DIY projects. It offers a straightforward application.

However, for high-traffic or long-term installations, professionals often prefer more durable options. These include glued vinyl, hardwood, or our own SPC and LVT products. Self-adhesive vinyl is not usually my top recommendation for Aiden or Lori. They are large-scale distributors who focus on quality that lasts and can handle high traffic. It is generally not recommended for living rooms or entryways due to potential adhesive degradation over time.

Usage Comparison Table

For professionals, self-adhesive flooring finds its niche in:

- Low-traffic residential areas: Bedrooms, closets, or basements with very light foot traffic.

- Temporary commercial spaces: Pop-up shops, trade show booths, or short-term rental units.

- Budget-conscious projects: When the lowest upfront cost and fastest installation are the main priorities, and longevity is less critical.

It is rarely chosen for main living areas in homes or high-traffic commercial zones. These areas demand a more robust solution. My factory produces both LVT and SPC. I know these options offer superior long-term performance.

| Flooring Type | Installation Ease | Professional Use (Typical) | Best Use Case |

|---|---|---|---|

| Self-Adhesive Vinyl | High (DIY-friendly) | Limited (specific, low-traffic) | Short-term, budget-friendly, DIY |

| Click-Lock SPC/LVT | Medium (DIY/Pro) | High (residential, commercial) | Long-term, medium to high traffic |

| Dry-Back LVT | Low (Pro-recommended) | High (heavy commercial, industrial) | Long-term, very high traffic |

What is the expected durability and lifespan of Self-Adhesive flooring?

How long does self-adhesive flooring truly last? Many wonder if it is a short-term fix. We need to look at its real lifespan and common durability concerns.

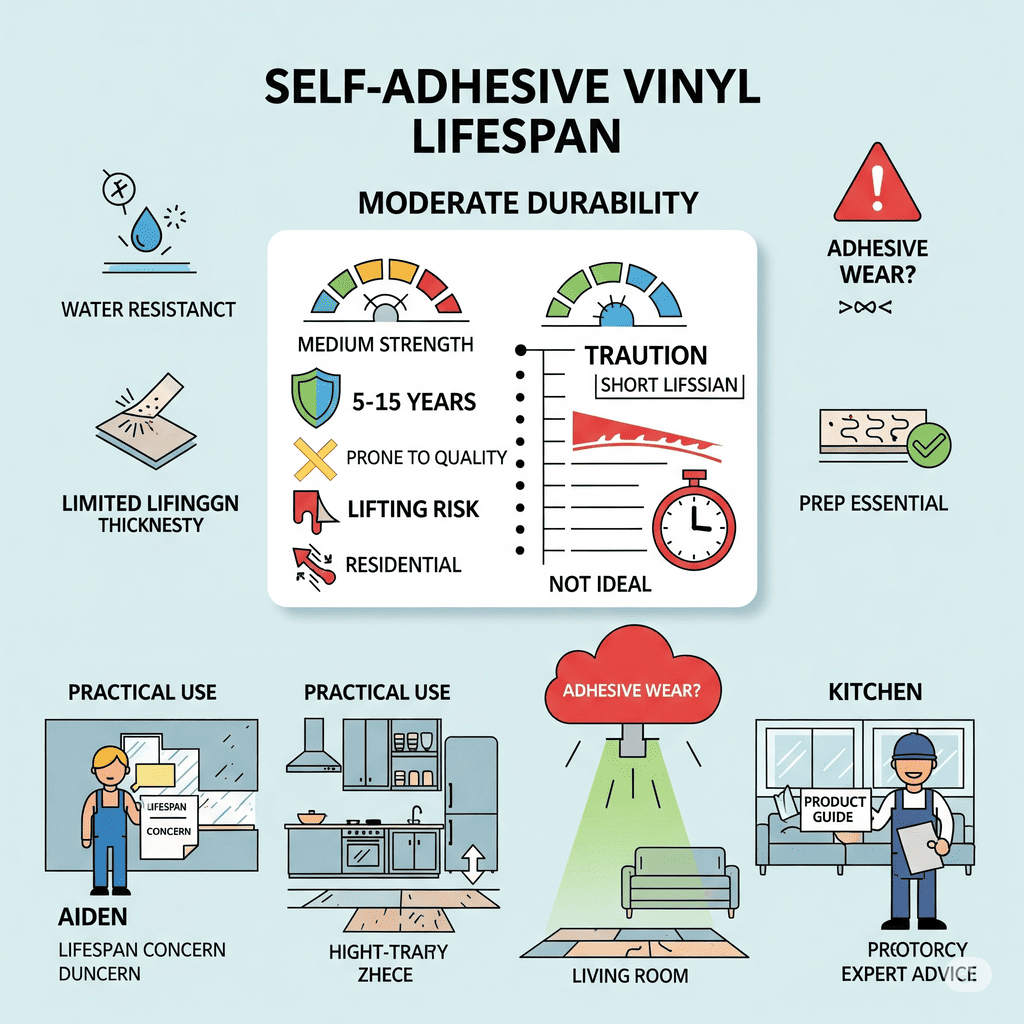

The durability of self-adhesive vinyl flooring is moderate, suitable for regular use in spaces like kitchens or powder rooms. It has a shorter lifespan than materials like stone or hardwood. Its lifespan is often limited by adhesive breakdown and a thin wear layer, leading to issues like lifting, shifting, or damage in high-traffic areas.

I have seen products that perform well, and some that fail quickly. The lifespan of self-adhesive flooring depends on many factors. It is not a "set it and forget it" solution. Aiden, my client from the UK, always asks about lifespan and warranties. He needs to know the product will hold up for his customers. For self-adhesive vinyl, it can withstand foot traffic and spills but has a shorter lifespan compared to materials like stone, hardwood, or advanced vinyl with thicker wear layers.

Key Factors Influencing Lifespan

Several elements play a role in how long self-adhesive flooring will last:

- Wear Layer Thickness: This is the clear protective layer on top. A thinner wear layer is prone to nicks, chips, and deep cuts, especially in high-traffic areas.

- Adhesive Quality: The quality of the pre-applied adhesive is crucial. Adhesive breakdown is a common issue, causing tiles to lift or shift.

- Subfloor Preparation: As I will explain later, a perfectly smooth and clean subfloor is non-negotiable. Poor prep directly reduces lifespan.

- Traffic Levels: High foot traffic wears down any flooring faster. Self-adhesive vinyl is not ideal for long-term, heavy-use environments like busy living rooms or entryways.

- Maintenance: Proper cleaning and care can extend the life of the floor, but it does not overcome inherent durability limits.

In a typical residential setting with light to moderate traffic, self-adhesive flooring can last several years. This assumes good quality material and proper installation. However, compared to the decades-long lifespan of materials like stone or hardwood, or the long lifespan of our quality SPC/LVT, it is a shorter-term solution.

Durability Concerns and Lifespan Limits

Common durability concerns for self-adhesive vinyl include:

- Adhesive Breakdown: This is the most significant concern. It causes tiles to lift, shift, or curl over time. This is especially true in large spaces or areas with temperature fluctuations.

- Thin Wear Layer: The wear layer is often thin. This makes the flooring susceptible to scratches, nicks, and deep cuts from furniture, pet claws, or even regular foot traffic.

- Gaps Between Tiles/Planks: As the adhesive degrades, gaps may appear between individual pieces. This can happen over time and can necessitate replacing individual pieces. While its modular design allows for easy replacement, it highlights its durability limitations.

To get the most out of self-adhesive flooring: choose products with a thicker wear layer if possible, ensure the subfloor is perfectly smooth, and avoid using it in very high-traffic areas. While self-adhesive can be a convenient option, its durability cannot match the robust nature of click-lock SPC or dry-back LVT. My factory focuses on providing products that give our clients confidence in their longevity and performance.

| Durability Factor | Impact on Self-Adhesive Lifespan | Typical Lifespan (Residential) |

|---|---|---|

| Thin Wear Layer | Significantly decreases | Shorter (5-10 years typical) |

| Adhesive Breakdown | Major cause of failure | Shortens lifespan |

| Poor Subfloor Prep | Crucially shortens lifespan | Significantly reduced |

| High Traffic Areas | Not recommended, very short lifespan | 1-3 years (if used) |

| Moderate Traffic | Moderate lifespan | 5-15 years |

How do subfloor preparation requirements differ for Self-Adhesive flooring?

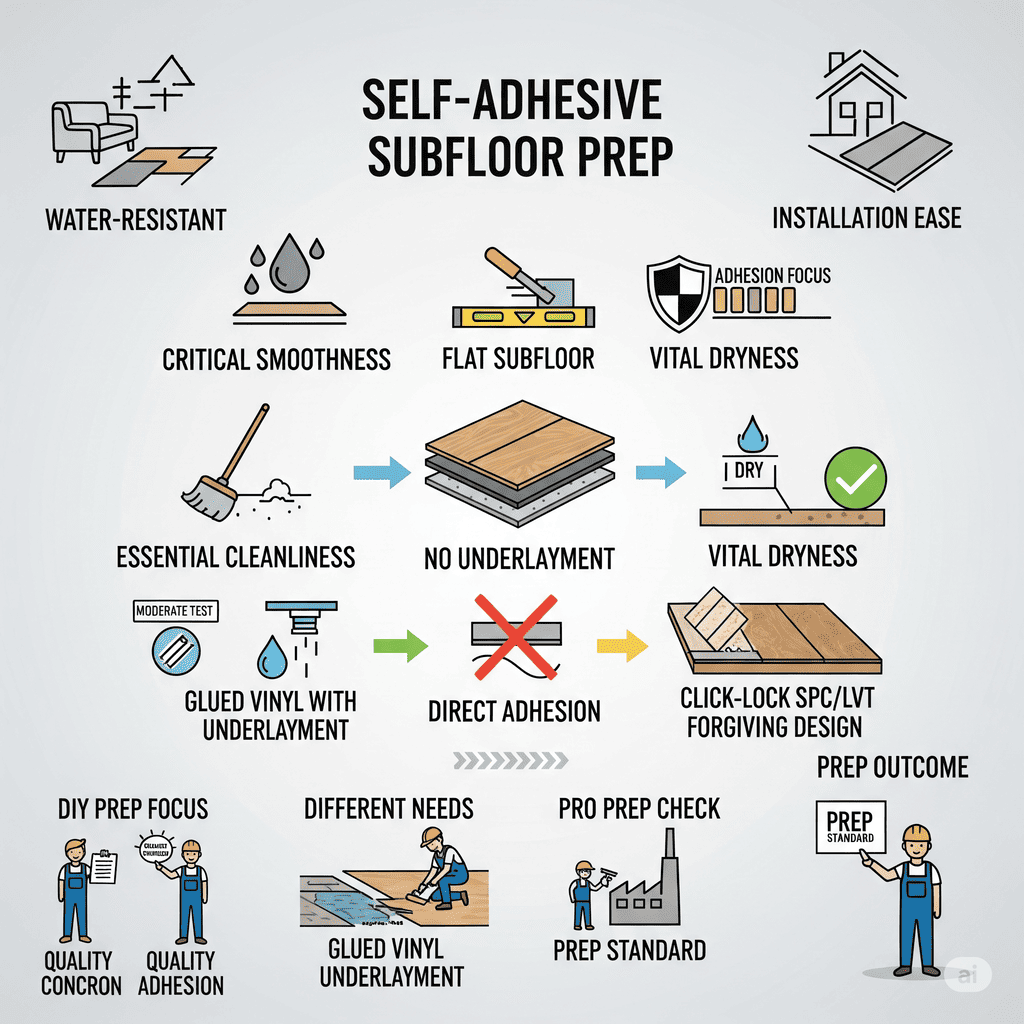

Is subfloor preparation for self-adhesive different? Bad prep leads to big problems. We need to understand the right way. The evidence leans toward needing a clean, smooth subfloor. It differs from glued vinyl by not requiring underlayment.

Subfloor preparation for self-adhesive flooring is critical and often more demanding than for other vinyl types. The subfloor must be exceptionally smooth, clean, dry, and free of imperfections. Any unevenness will show through and compromise adhesion. It adheres directly to the existing floor, unlike glued vinyl which might use additional underlayment.

I have learned from my years in this business that subfloor preparation is often overlooked. But for self-adhesive flooring, it is the most critical step. My clients, like Aiden and Lori, often deal with issues related to installation. I always stress the importance of a perfect subfloor for this type of product. The subfloor must be clean, smooth, level, and free of debris, with any cracks or imperfections repaired to ensure a flawless surface.

The Importance of Smoothness and Cleanliness

Self-adhesive planks are thin and flexible. This means they will "telegraph" any imperfections from the subfloor. A tiny bump or divot on the subfloor will show right through the surface of the vinyl. This creates an uneven look. More importantly, it creates pressure points that weaken the adhesive bond over time. The adhesive needs full contact with a perfectly flat surface to stick correctly. Any air pockets or uneven spots will lead to premature peeling or lifting. This is a common pain point for buyers who see quality differences after receiving goods. Even small particles of dust can prevent the adhesive from bonding effectively.

No Underlayment Needed

One key difference is that self-adhesive vinyl flooring does not require additional underlayment. It adheres directly to the existing floor. This simplifies the installation process compared to traditional glued vinyl, which sometimes requires a separate underlayment layer. However, this convenience also means that the subfloor itself must act as the perfect base. Any old glue, paint, or other residues must be completely removed or smoothed over, as they can interfere with the new adhesive. Cracks or holes must be filled and made smooth. This makes installation easier but emphasizes the importance of a well-prepared base for adhesion1.

Why Preparation is Paramount for Adhesion

The self-adhesive backing forms the entire bond between the plank and the subfloor. Unlike click-lock systems that connect planks to each other, or dry-back which uses a liquid adhesive spread over the entire surface, self-adhesive relies solely on its pre-applied sticky layer. If that layer cannot make full, even contact, the floor will fail. This means edges will peel, planks will shift, and gaps will appear. This can lead to missed selling seasons for distributors if they have to deal with returns. This is why I always emphasize top-quality materials and rigorous quality control for my clients. Moisture testing is also essential, especially on concrete, as the adhesive will not stick to a wet surface, and moisture can lead to mold.

| Subfloor Requirement | Self-Adhesive | Glued Vinyl (Typical) | Click-Lock SPC/LVT |

|---|---|---|---|

| Smoothness | Critical | Very Important | Important |

| Cleanliness | Critical | Critical | Important |

| Dryness | Critical | Critical | Important |

| Underlayment Needed | No | Sometimes | No (often integrated pad) |

| Imperfections | Highly visible | Less visible with glue | Most forgiving |

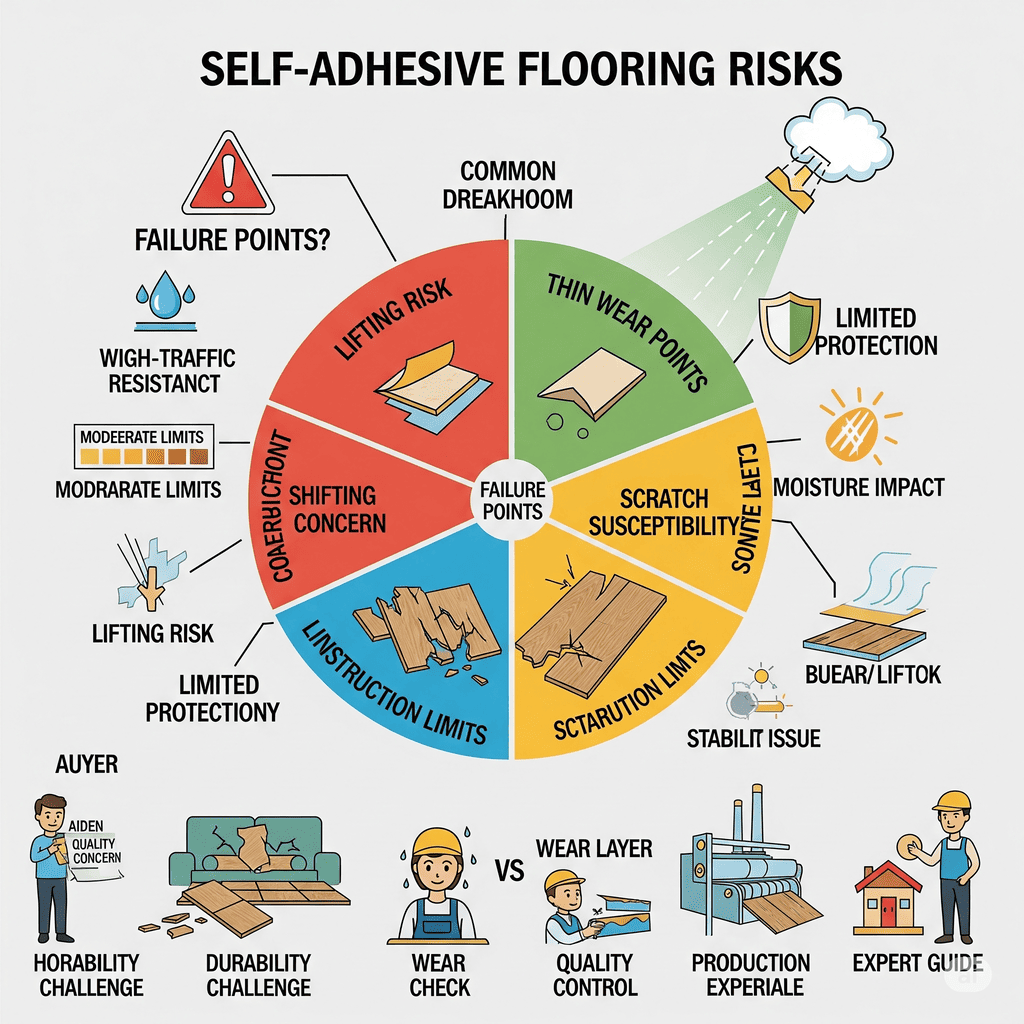

What are the common failure points and durability concerns for Self-Adhesive flooring?

What goes wrong with self-adhesive flooring? Knowing issues helps avoid costly mistakes. We need to identify the pitfalls. Common issues include adhesive failure1 and thin wear layers, limiting use in high-traffic areas.

Common failure points for self-adhesive flooring include adhesive breakdown, which leads to tiles lifting, shifting, or curling over time. The thin wear layer is another concern, making it susceptible to scratches, nicks, and deep cuts, particularly in high-traffic areas. Gaps between tiles or planks may also appear as the adhesive degrades.

I often hear from clients who have tried self-adhesive flooring from other suppliers and faced problems. They complain about quality differences after receiving the goods. These issues can damage a distributor’s reputation. I focus on preventing these problems for my CloudsFlooring clients. The information shows that adhesive breakdown is particularly common.

Adhesion Failure and Its Roots

The most common problem is adhesion failure. This happens when the self-adhesive backing does not stick properly to the subfloor or loses its bond over time. This is a primary durability concern.

- Peeling Edges/Corners: This occurs when the edges of the planks lift from the subfloor. Causes include inadequate subfloor prep (dust, debris, unevenness), low-quality adhesive, or excessive temperature changes. If a room gets very hot then very cold, the planks expand and contract, putting stress on the adhesive. This can lead to tiles lifting, shifting, or curling.

- Gapping Between Planks: Spaces appear between individual planks. This often happens after adhesion failure. Planks shift because they are no longer firmly bonded. This also links to poor subfloor prep or temperature fluctuations.

- Bubbling or Lifting: This is when air gets trapped under the plank, causing a raised area. This can be due to moisture under the flooring, or uneven adhesive application during manufacturing.

To prevent these, I always suggest rigorous quality control, from the factory to the end-user. My clients in North America, the UK, and the Middle East expect this level of reliability.

Visible Wear and Tear

Beyond adhesion issues, self-adhesive flooring can show other signs of wear quickly:

- Scratches and Scuffs: The wear layer on self-adhesive planks is often thinner. This makes it more prone to visible scratches from furniture, pet claws, or foot traffic. It is susceptible to nicks, chips, and deep cuts.

- Indentations: Heavy objects can leave permanent dents. The core of self-adhesive planks may not be as dense as SPC or LVT, offering less resistance to impact.

- Fading: Prolonged exposure to direct sunlight can cause the color of the vinyl to fade over time.

These issues directly impact the aesthetic appeal and customer satisfaction. Lori, my US client, is very sensitive to quality. She needs products that maintain their appearance for a long time. While replacing individual pieces is possible due to its modular design, it highlights its durability limitations and may not be as seamless as with other flooring types.

| Failure Point | Common Cause | Impact on Floor Performance |

|---|---|---|

| Adhesive Breakdown | Poor subfloor prep, low-quality adhesive, temperature swings | Lifting, shifting, curling, gaps |

| Thin Wear Layer | Inadequate protection | Scratches, nicks, deep cuts |

| Gaps Between Planks | Adhesive degradation, shifting | Unsightly, trip hazard |

| Bubbling/Lifting | Moisture, trapped air | Uneven surface, bond loss |

| Indentations | Weak core, heavy objects | Permanent marks |

How does wear layer thickness and construction limit Self-Adhesive flooring’s performance?

How does wear layer impact self-adhesive? It is more than just aesthetics. We need to see how it truly limits performance. Wear layer thickness likely impacts performance, making it less suitable for heavy use compared to thicker options.

The wear layer thickness and overall construction significantly limit self-adhesive flooring’s performance, especially in high-traffic areas. Thinner wear layers offer less protection against scratches and dents, reducing durability compared to thicker, more robust vinyl options. The peel-and-stick construction itself can lead to adhesive degradation over time.

The wear layer is the unsung hero of vinyl flooring. I often discuss this with my clients. They need to understand that not all vinyl is created equal. The internal construction and wear layer are key indicators of quality and performance, especially for distributors like Aiden and Lori who focus on high-quality products. BuildDirect notes that the thin wear layer is a key limitation, making it susceptible to damage in high-traffic areas.

Understanding the Wear Layer

The wear layer is the transparent top coating that protects the vinyl design layer. It is made of urethane, sometimes with an added ceramic bead or aluminum oxide for extra durability. Its thickness is measured in mils (thousandths of an inch) or millimeters. For self-adhesive flooring, the wear layer is often on the thinner side, typically ranging from 2 to 6 mils. This is suitable for very light residential traffic. It offers less protection against wear and tear.

In contrast, high-quality SPC or LVT products, like those we manufacture at CloudsFlooring, often feature wear layers from 12 mils to 28 mils. Some commercial-grade LVT can even go up to 40 mils. A thicker wear layer means:

- Better Scratch Resistance: It acts as a shield against daily wear and tear.

- Improved Scuff Resistance: Reduces marks from shoes and objects.

- Increased Longevity: The floor maintains its appearance for a longer time.

My company prides itself on offering customizable, top-quality LVT and SPC. This ensures that our clients receive products with robust wear layers suitable for their markets. For example, a 22 mil wear layer with enhanced scratch resistance significantly boosts durability.

Impact of Core and Backing

Beyond the wear layer, the overall construction of a self-adhesive plank also limits its performance.

- Core Material: Self-adhesive vinyl typically has a flexible PVC core. This makes it easy to cut and install. However, this flexibility also means it offers less dimensional stability and impact resistance compared to the rigid core of SPC flooring. SPC’s stone-plastic composite core is much denser, making it highly resistant to dents and temperature changes. This is a big reason why Lori, my US client, prefers SPC for her projects.

- Backing Layer: The peel-and-stick construction, while convenient, relies solely on its pre-applied adhesive. This can lead to adhesive degradation over time, potentially causing lifting or shifting. It does not provide the same structural integrity as the solid backing found on dry-back LVT or the integrated underlayment sometimes seen on click-lock SPC.

These construction differences mean self-adhesive flooring is inherently less robust for demanding environments. Replacing damaged sections is possible due to its modular design, but this may not be as seamless as with other flooring types, further limiting its performance in demanding settings.

| Aspect | Self-Adhesive Vinyl (Typical) | CloudsFlooring Vinyl (SPC/LVT) |

|---|---|---|

| Wear Layer | 2-6 mil (thin) | 12-28 mil (or higher, robust) |

| Core Material | Flexible PVC | Rigid SPC / Flexible LVT |

| Dimensional Stability | Moderate (prone to movement) | High (stable, less prone to movement) |

| Impact Resistance | Low (prone to dents/chips) | High (resistant to dents/impacts) |

| Adhesion Method | Pre-applied adhesive (can degrade) | Click-lock / Strong liquid adhesive |

| Commercial Viability | Limited (not for heavy traffic) | High (suitable for most commercial) |

Conclusion

Self-adhesive vinyl flooring offers quick installation for light-duty, DIY projects. However, for true durability and professional applications, superior subfloor preparation, thicker wear layers, and robust construction found in LVT and SPC are essential.

The above data is for reference only.