Struggling to pinpoint the next big thing in flooring from China? Ignoring emerging trends can mean missed opportunities and outdated stock. I’m here to guide you through the essential shifts.

Key trends for international distributors include the significant rise of SPC flooring. Also, transformative advancements in digital printing and texturing are enhancing aesthetics. Finally, there’s a growing emphasis on sustainable materials and manufacturing within China’s flooring sector.

Navigating the dynamic Chinese flooring market can feel overwhelming. Understanding these key developments is crucial for your business success. As someone who works directly with production lines here at CloudsFlooring, I see these changes firsthand.

Let’s break down what you, as an international distributor, need to keep an eye on. This insight will help you make smarter sourcing decisions. It will also help you stay ahead of your competition. Keep reading to discover how these trends can benefit your bottom line and delight your customers.

Are there shifts in dominant product types (e.g., SPC vs. LVT vs. Laminate) within Chinese flooring production?

Unsure which flooring types will bring the best returns next season? Choosing the wrong products can tie up capital and hurt your profits. Let’s look at what’s really happening on the factory floors in China.

Yes, SPC (Stone Plastic Composite) flooring is rapidly becoming a dominant force in Chinese flooring production. It often outpaces LVT (Luxury Vinyl Tile) and traditional laminate. This is due to its superior durability, waterproof features, and ease of installation. Manufacturers are heavily investing accordingly.

I’ve seen this shift firsthand at CloudsFlooring. As a factory owner with both LVT and SPC lines, the change is clear. For years, LVT was the go-to for many of my clients. Mark in Canada, for example, appreciated its balance of aesthetics and performance, especially our click lock and dry back varieties.

However, the demand for SPC flooring has truly exploded in recent years. Clients like Lori in the US are increasingly asking for it. Why this significant change? SPC offers a few key advantages that are particularly appealing.

Key Drivers for SPC’s Ascendancy

| Feature | Advantage for SPC Flooring | Implication for Distributors & Buyers |

|---|---|---|

| Core Composition | Rigid core, often limestone-based. | Extreme dent resistance, feels very solid. |

| Waterproof Nature | 100% waterproof, not just water-resistant. | Ideal for all rooms, including wet areas. |

| Temperature Stability | Minimal expansion/contraction. | Suitable for wide temperature variations. |

| Ease of Installation | Click-lock systems are common and refined. | Faster, potentially lower-cost installs. |

These factors make SPC a very compelling option. Its robustness addresses common pain points like damage during shipping or after installation, which is a concern for buyers like Mark and Lori who prioritize quality.

Comparative Overview: SPC vs. LVT vs. Laminate

| Feature | SPC Flooring | LVT Flooring | Laminate Flooring |

|---|---|---|---|

| Primary Material | Stone Plastic Composite | Polyvinyl Chloride | High-Density Fiberboard (HDF) |

| Water Resistance | Excellent (100% Waterproof) | Good (Water-resistant) | Poor (Susceptible to swelling) |

| Durability | Very High (Resists dents, impacts) | High (Can dent from sharp impacts) | Moderate (Can scratch/chip) |

| Producer Focus | Rapidly Increasing in China | Steady, but SPC growing faster | Decreasing for general use |

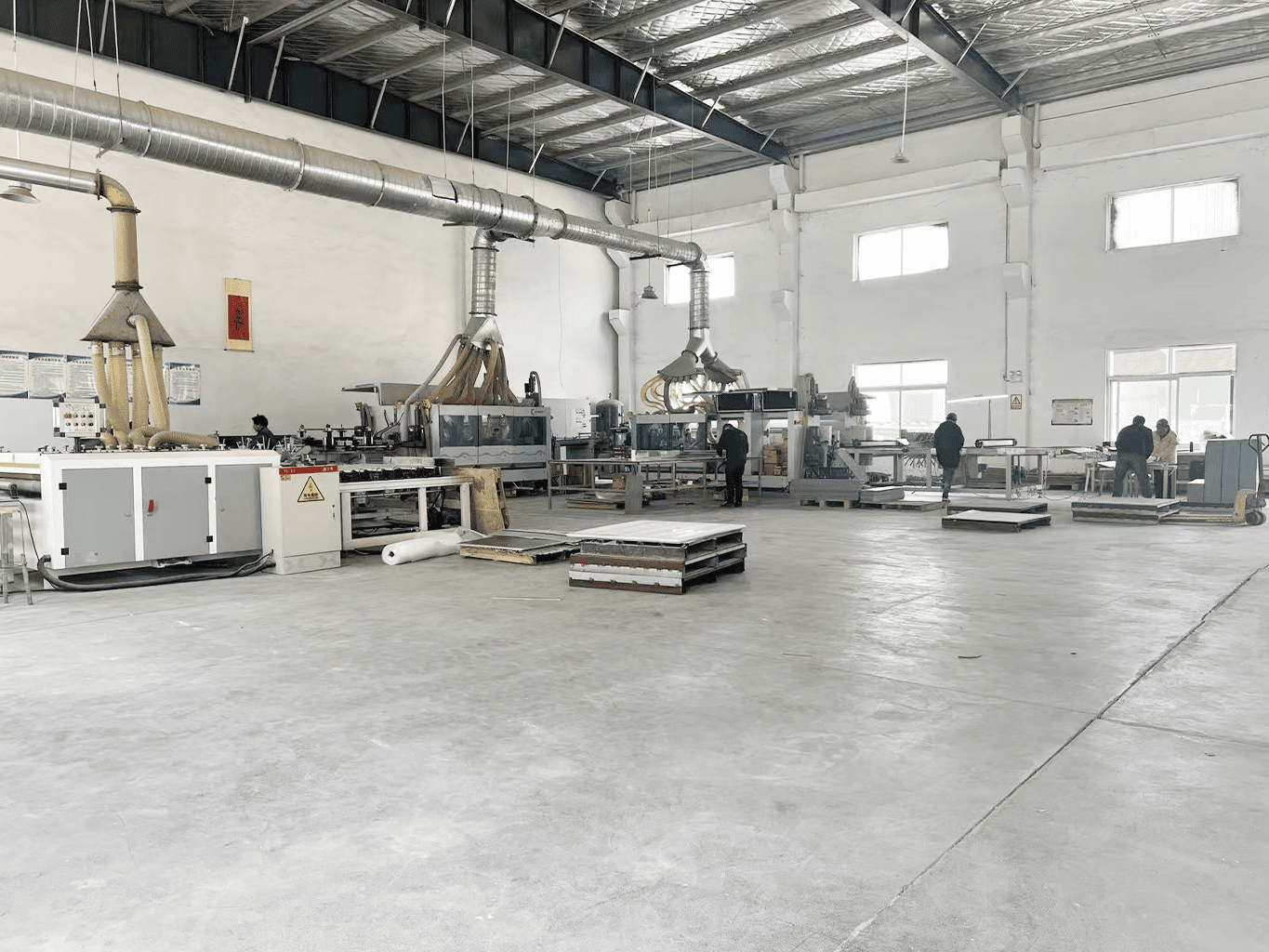

At CloudsFlooring, we’ve proactively responded. We significantly expanded our SPC production capabilities. While our three LVT lines continue to produce top-quality click lock, dry back, and self-adhesive options, our two dedicated SPC lines are busier than ever.

The interest from North America, the UK, and the Middle East for SPC is undeniable. Laminate, while still available, sees its market share squeezed by these more resilient and water-friendly vinyl options. For you as a distributor, understanding this shift is key for smart inventory and meeting modern customer demands.

How are advancements in digital printing and texturing technology impacting Chinese flooring aesthetics?

Are your current flooring designs failing to excite customers? If your competitors offer more realistic and varied aesthetics, you could be losing sales. Let’s explore how Chinese manufacturers are upping their game.

Digital printing and advanced texturing, especially Embossed In Register (EIR) technology1, are revolutionizing Chinese flooring aesthetics. This means hyper-realistic wood and stone looks. It also means greater design customization and a wider variety of unique styles for distributors.

I get particularly excited when I talk about these aesthetic advancements. They directly impact one of our core strengths at CloudsFlooring: offering top-quality, customizable, and often rare styles. The days when vinyl flooring looked obviously artificial are long gone.

The technological leaps in China’s flooring factories are remarkable. For clients like Mark and Lori, who understand sales but might not have a deep background in aesthetics, these advancements are a game-changer. They mean access to products that truly sell themselves through visual and tactile appeal.

Key Aesthetic Technologies and Their Benefits

| Technology | Core Function | Impact on Flooring Aesthetics | Distributor Advantage |

|---|---|---|---|

| High-Definition Digital Printing | Prints complex designs directly onto the film layer. | Sharper, more vibrant, and diverse patterns. Endless design possibilities. | Offer unique, exclusive, or highly customized designs. |

| Embossed In Register (EIR) | Aligns surface texture precisely with the printed visual pattern. | Incredibly realistic look and feel, mimicking natural wood grain or stone texture. | Premium product appeal, justifying higher price points. |

| Advanced Texturing | Creates deeper, more varied surface finishes (e.g., hand-scraped, brushed). | Enhanced realism, greater tactile variety, sophisticated feel. | Cater to diverse customer preferences for texture. |

At CloudsFlooring, we’ve invested heavily in these technologies. This applies to both our LVT and SPC lines. This investment allows us to offer our B2B clients—large company buyers and vinyl flooring distributors—products that truly stand out.

Imagine offering LVT that perfectly replicates a rare, reclaimed wood. Or SPC that has the exact look and feel of Italian slate. This is the level of realism and customization we can now achieve. It directly addresses a key distributor pain point: differentiating products in a crowded market.

For buyers like Mark, who rebrand products, superior aesthetics mean stronger brand appeal. For Lori, who focuses on quality, these technologies contribute to a premium end-product. It means fewer complaints about products not matching expectations in terms of looks.

Are Chinese flooring industries increasingly focusing on sustainable materials and production methods?

Are your customers asking for eco-friendly flooring1 more often? Ignoring the growing demand for sustainability can limit your market reach and brand reputation. Let’s see how Chinese flooring producers are responding.

Yes, many Chinese flooring manufacturers are definitely increasing their focus on sustainable materials. They are also adopting greener production methods. This includes using recycled content, reducing VOC emissions, and aiming for certifications recognized in export markets.

This trend is something I’m personally passionate about. It’s also becoming increasingly important for our clients in North America, the UK, and parts of the Middle East. The demand for "green" products is a fundamental shift.

For distributors working with buyers like Mark or Lori, this is key. Being able to guarantee and certify the eco-credentials of flooring is a significant selling point. It directly addresses concerns about quality and responsible sourcing. It also helps avoid issues with falsified certificates, a major pain point.

Pillars of Sustainability in Chinese Flooring Manufacturing

| Sustainability Pillar | Common Actions by Chinese Manufacturers | What Distributors Should Verify |

|---|---|---|

| Responsible Materials | Increased use of recycled content (e.g., PVC). Use of virgin PVC with fewer phthalates. Limestone in SPC. | Material composition declarations. Recycled content verification. Phthalate-free claims. |

| Greener Production | Investment in energy-efficient machinery. Water recycling systems. Waste reduction programs. Lowering VOCs. | Supplier environmental policies. ISO 14001 certification. On-site audits if feasible. |

| Product Safety | Meeting low VOC emission standards. Compliance with chemical restrictions (e.g., REACH). | FloorScore®, GREENGUARD Gold certifications. Test reports for specific chemical content. |

| Certifications | Seeking globally recognized standards. | Authenticity and validity of provided certificates. Relevance to your target market. |

At CloudsFlooring, we are actively working to enhance the sustainability profile of our LVT and SPC flooring. This involves careful raw material selection. We also optimize our production lines (three for LVT, two for SPC) to reduce waste.

Crucially, we focus on ensuring our products meet the stringent VOC emission standards required by our export markets. We understand that certifications are vital. They are not just pieces of paper. They are crucial for market access and for building trust with your customers.

This commitment to genuine sustainability and transparent certification helps mitigate risks for buyers. It helps avoid the disappointment of receiving goods with quality issues or non-compliant products. We aim to provide flooring that is top quality, stylish, and responsibly made.

Common Certifications to Look For

| Certification | Focus Area | Importance for Distributors |

|---|---|---|

| FloorScore® | Indoor Air Quality (Low VOC emissions2) | Widely recognized in North America for green building standards. |

| GREENGUARD Gold | Indoor Air Quality (Stricter VOC limits) | Indicates very low chemical emissions, suitable for sensitive environments. |

| ISO 14001 | Environmental Management System (Factory-level) | Shows manufacturer’s commitment to managing environmental impact. |

| CE Marking | Health, safety, environmental protection (EU) | Required for products sold within the European Economic Area. |

Checking for these certifications can give you and your customers greater confidence.

Conclusion

In summary, China’s flooring industry is dynamic. Key trends like SPC’s dominance, aesthetic technology leaps, and the green shift are crucial. Staying informed helps you thrive as a distributor.