Have you ever found a deal that seemed too good to be true? As an importer, spotting hidden quality risks before you source flooring is crucial. Ignoring these signs can lead to costly mistakes, damaging your reputation and bottom line.

When sourcing flooring, hidden quality risks often lie in core material integrity, wear layer durability, and inconsistent manufacturing processes. These factors can lead to issues like poor locking systems, dimensional instability, and color variations, costing importers significantly in claims and lost business.

I have seen many importers chase the lowest price, only to face huge problems down the line. Understanding these risks upfront can save you immense headaches and ensure your customers receive the quality they expect. Let’s dig deeper into what you should look out for.

Can extremely cheap flooring indicate compromises in core materials, wear layer thickness, or QC processes?

Are you wondering if that incredibly low price tag signals a hidden problem? It often does. Extremely cheap flooring frequently points to significant compromises in the very foundations of the product.

Yes, incredibly cheap flooring almost always indicates compromises in core material quality, thinner wear layer thickness, and lax quality control processes. These cost-cutting measures directly impact the product’s durability, performance, and overall lifespan, leading to issues for importers.

At CloudsFlooring, my team and I have spent years perfecting our production process, and I know firsthand where corners get cut. When the price is too low, it usually means sacrifices have been made in the raw materials or the manufacturing care. This directly affects the quality you deliver to your clients.

Core Material Quality1: The Foundation of Your Floor

The core material is the heart of LVT and SPC flooring. For SPC, it is primarily stone powder and virgin PVC. For LVT, it is PVC and stabilizers.

When I see prices that are far below market average, my first thought goes to the quality of these raw materials. Many cheap producers use a high percentage of recycled or inferior PVC. This can introduce impurities and reduce the stability of the plank. They might also use less stone powder or lower-grade additives for SPC. This makes the core weak and brittle.

This significantly impacts the floor’s ability to withstand daily wear and tear. This is especially true in high-traffic areas. It can even introduce harmful substances if not properly regulated. For example, during one of my factory visits to a competitor, I noticed the raw material area was messy. Various grades of recycled plastic were mixed together. This was a clear red flag.

Wear Layer Thickness2: The Shield of Durability

The wear layer is the transparent top coating. It protects the printed design layer from scratches, scuffs, and stains. Its thickness is measured in millimeters (mm) or mils (thousandths of an inch). A common wear layer for residential use might be 0.3mm. Commercial applications often require 0.5mm or even 0.7mm.

When flooring is extremely cheap, producers often reduce this critical layer. A thinner wear layer means the floor will wear out much faster. It will show signs of damage, dullness, or even expose the print film prematurely. This leads to customer complaints and premature replacement needs. My team always emphasizes the importance of a pure PVC wear layer with proper UV coating. Anything less will simply not hold up.

Quality Control (QC) Processes3: The Unseen Costs

Proper quality control is an investment. It involves rigorous testing at every stage. This goes from incoming raw materials, through extrusion and pressing, to final dimension checks and packaging.

Cheap flooring often comes from factories that skip these crucial steps. They might not test for phthalates, heavy metals, or even basic dimensional stability. Their inspection process might be minimal. It may rely only on a quick visual check.

This lack of rigorous QC means inconsistencies in color, thickness, and even the chemical composition within a single batch. Aiden and Lori’s pain points often revolve around receiving goods that do not match samples or have unexpected quality issues. Without strong QC, you are essentially gambling on every container.

| Aspect | High Quality (CloudsFlooring) | Cheap Quality (Risks) |

|---|---|---|

| Core Material | 100% Virgin PVC/Stone, balanced composition | High recycled content, inconsistent mix, stability issues |

| Wear Layer | 0.3mm to 0.7mm+, pure PVC, UV coated | Often less than 0.3mm, poor coating, wears quickly |

| QC Process | Multi-stage lab testing, strict inspection | Limited/no testing, visual checks only, high defect rate |

Are issues like poor locking system fit, dimensional instability, or color inconsistency more common with Cheap flooring?

Have you ever unboxed a new product only to find it does not quite fit together as it should? When it comes to flooring, such issues can derail an entire project.

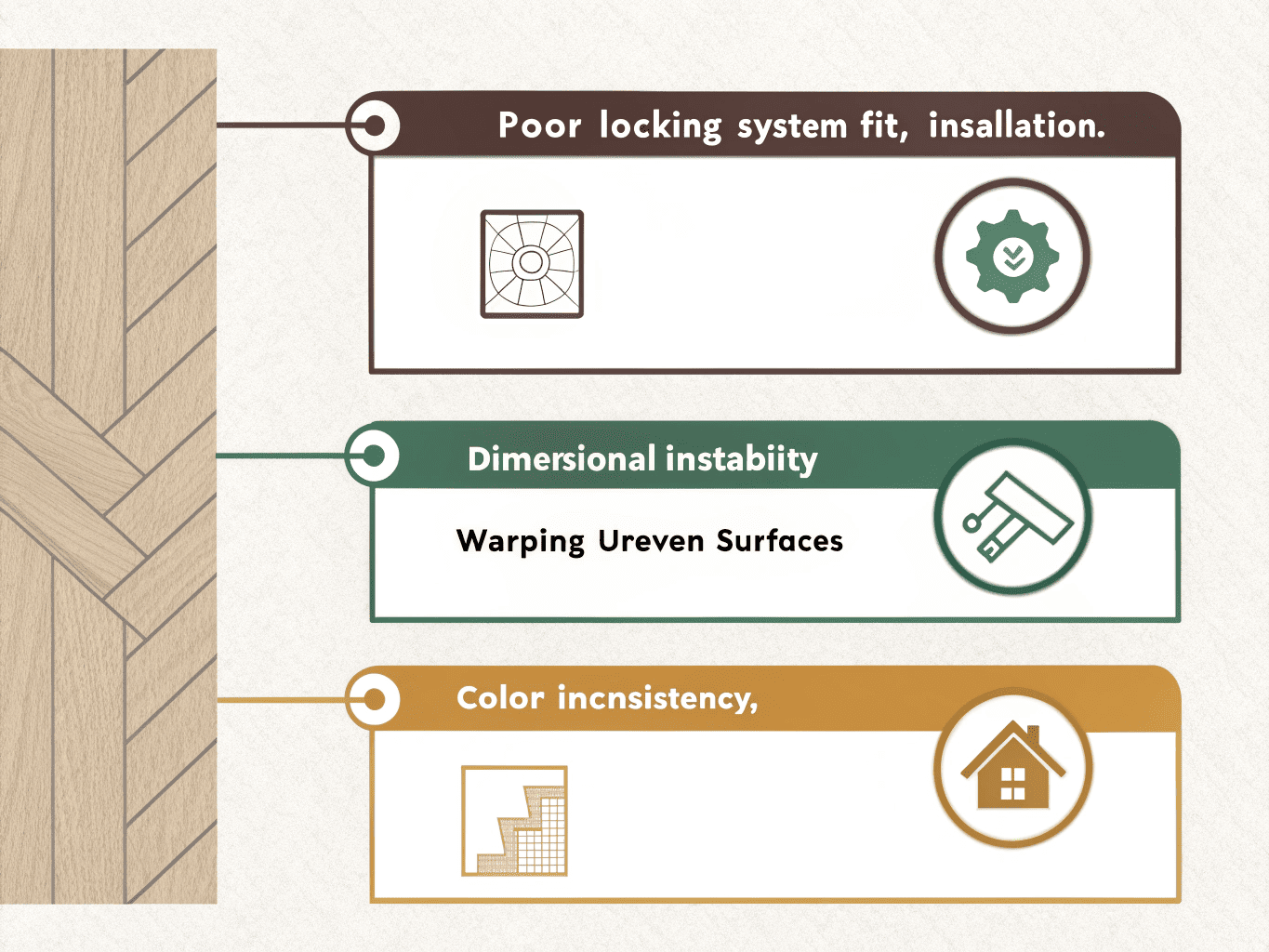

Yes, issues like poor locking system fit, dimensional instability, and color inconsistency are significantly more common with cheap flooring. These problems arise from lower quality raw materials, imprecise manufacturing, and inadequate quality control, leading to installation headaches and customer dissatisfaction.

I recall a situation where one of our potential clients, an importer like Aiden, showed me photos of a "bargain" shipment he received. The floorboards would not click properly, and some were visibly warped. This is exactly what happens when you prioritize price over precision.

Poor Locking System Fit: The Installation Nightmare

The locking system is what holds click-lock flooring together. It provides a seamless and stable surface. High-quality flooring uses precision-milled profiles. These lock tightly and securely.

Cheap flooring, however, often suffers from poorly manufactured locking systems. This can be due to inferior cutting machinery, inconsistent materials, or rushed production.

The result? Planks that do not click together easily. This leaves gaps, creates uneven surfaces, or even breaks during installation. This frustration for installers and end-users leads to higher labor costs, delays, and a less durable, visually unappealing floor. My production lines use advanced European milling equipment. This ensures every click system is perfect.

Dimensional Instability: The Warping Problem

Dimensional stability refers to a flooring plank’s ability to maintain its original size and shape. This is true despite changes in temperature and humidity. Vinyl flooring, especially SPC, is known for its excellent stability.

However, this property is severely compromised in cheap products. Producers of low-cost flooring often use unstable core materials, inadequate stabilizers, or improper cooling processes during manufacturing.

This leads to planks that expand, contract, warp, or cup significantly when exposed to environmental changes. Imagine an importer like Lori receiving a container of SPC flooring only to find planks curling up or shrinking. This leaves visible gaps after installation. This is a massive problem. It can cause the entire floor to fail prematurely. This necessitates costly repairs or even full replacement. It erodes all potential profit margins.

Color Inconsistency: The Aesthetic Compromise

The visual appeal of flooring is paramount. Color consistency across planks and between different production batches is essential. It leads to a professional and attractive installation.

Cheap flooring frequently suffers from color inconsistency. This can be due to using low-grade pigments that fade unevenly. It can also be from inconsistent mixing of raw materials or poor printing technology. You might find noticeable shade variations within a single carton. Worse, this can happen between different cartons in a shipment.

This creates a patchwork effect on the installed floor. This is a major aesthetic flaw. It is also a common reason for customer complaints. As someone who understands sales but sometimes lacks aesthetics, Aiden or Lori might not spot this until their own customers complain. This damages their brand reputation. My team ensures rigorous color matching and batch consistency checks to prevent this.

| Issue | Impact on Importer/Customer | Common Causes in Cheap Flooring |

|---|---|---|

| Poor Locking System | Difficult installation, gapping, breakage | Low-grade machinery, inconsistent milling, cheap profiles |

| Dimensional Instability | Warping, cupping, floor failure over time | Poor core material mix, improper curing, poor additives |

| Color Inconsistency | Unsightly floor, returns, complaints | Inconsistent pigment mixing, poor printing, batch variation |

How can importers balance the appeal of cheap prices with the potential costs of claims and reputational damage?

Are you torn between a fantastic price and the nagging doubt about quality? Finding the sweet spot between cost and reliability is a challenge every importer faces.

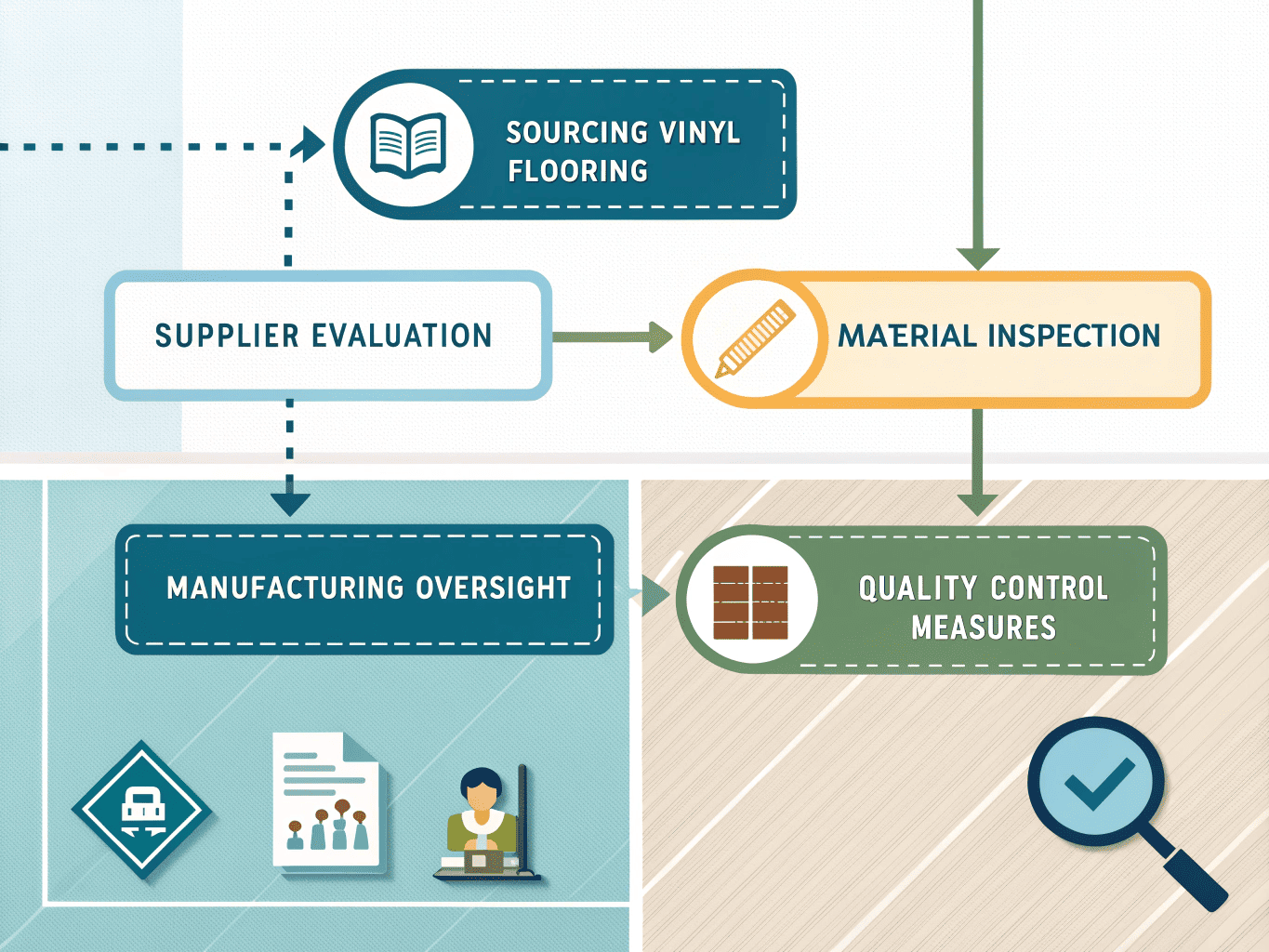

Importers can balance the appeal of cheap prices with potential costs by conducting thorough due diligence, prioritizing long-term supplier relationships, demanding certifications, and investing in third-party quality inspections. This proactive approach minimizes claims, protects reputation, and ensures consistent quality for their market.

My experience at CloudsFlooring has shown me that true value is not just about the invoice price. It is about the total cost of ownership1. This includes the hidden expenses of poor quality. My priority is always to help my clients understand this balance.

The Lure of Low Prices: A Calculated Risk?

I understand the immense pressure importers face. They need to secure the most competitive prices. In a global market, a lower unit cost can seem like the key. It may unlock higher profit margins and gain a competitive edge.

This is especially true for large company buyers and distributors like Aiden and Lori. They need to source at low prices to rebrand and distribute at higher prices in their home markets. The initial allure of a "bargain" supplier can be very strong.

However, this focus on the immediate unit cost often overlooks the potential downstream costs. These can quickly wipe out any perceived savings. Then they add even more. My factory is in China. We have seen many clients get burned by focusing solely on the cheapest option available.

The True Cost of Cheap: Beyond the Invoice

The hidden costs of cheap flooring are significant. They include:

-

Claims and Returns: Defective products lead to customer complaints. This requires replacements or refunds. This is not just about the cost of new flooring. It is also about shipping, labor for re-installation, and administrative overhead.

-

Reputational Damage: Word travels fast. If your rebranded product consistently has quality issues, your company’s reputation suffers. This can lead to lost future sales. It can also make it harder to attract new clients. For Aiden and Lori, whose business model relies on rebranding, this is a critical risk.

-

Logistical Headaches: Dealing with returns, quality checks, and shipping defective products back to China (if even possible) is time-consuming and expensive. This aligns with Aiden and Lori’s pain points regarding delayed shipments and inefficient communication.

-

Legal Fees: In severe cases, quality disputes can escalate to legal action. This incurs substantial costs.

-

Lost Opportunity: Time spent dealing with bad product is time not spent growing your business.

I have helped clients recover from situations. A single container of bad flooring cost them more than their profit for an entire year.

Mitigating Risks: My Recommendations

Balancing price and quality means being proactive and strategic.

-

Factory Visits and Audits: If possible, visit the factory in person. Or commission a third-party audit. Seeing the production lines, QC processes, and raw material storage firsthand tells you a lot.

-

Request Certifications: Always ask for and verify certifications. These include CE (for Europe) and FloorScore (for North America). These ensure products meet specific health, safety, and environmental standards. My factory holds both.

-

Detailed Contracts: Ensure your contract clearly outlines quality specifications, testing methods, and remedies for defects. Do not leave anything to assumptions.

-

Third-Party QC Inspections: Hire an independent inspection company to check the goods before shipment. They can perform pre-production, in-line, and final random inspections. This is a small investment. It offers huge protection.

-

Long-Term Partnerships: Build relationships with trusted suppliers. At CloudsFlooring, we work closely with our clients like Aiden and Lori. We provide transparent communication and consistent quality. This allows us to understand their specific needs and prevent issues before they arise.

| Risk Factor | Strategy for Mitigation (CloudsFlooring Approach) | Benefits |

|---|---|---|

| Unreliable Quality | Factory visits, detailed QC checks, certifications (CE, FloorScore) | Consistent product, fewer returns, stronger brand reputation |

| Communication Issues | Dedicated sales team, clear contract terms, regular updates | Efficient process, reduced delays, smooth logistics |

| Delivery Delays | Transparent production schedules, robust logistics partners | On-time delivery, never miss selling seasons, maintain cash flow |

| False Certifications | Verify with issuing body, ask for original documents | Ensures compliance, avoids legal issues, builds trust |

Conclusion

Evaluating hidden quality risks before sourcing is vital for importers. By scrutinizing core materials, wear layer, QC processes, and common issues like locking systems and dimensional stability, you avoid costly pitfalls. Balancing competitive prices with robust quality checks protects your brand and ensures long-term success.

The above data is for reference only.

-

Understanding the total cost of ownership helps importers make informed decisions, avoiding hidden expenses that can impact profitability. ↩ ↩

-

The thickness of the wear layer is vital for the longevity of flooring. Discover why it matters and how it impacts your investment. ↩

-

Effective quality control processes are essential for maintaining product standards. Learn about best practices to avoid costly mistakes. ↩