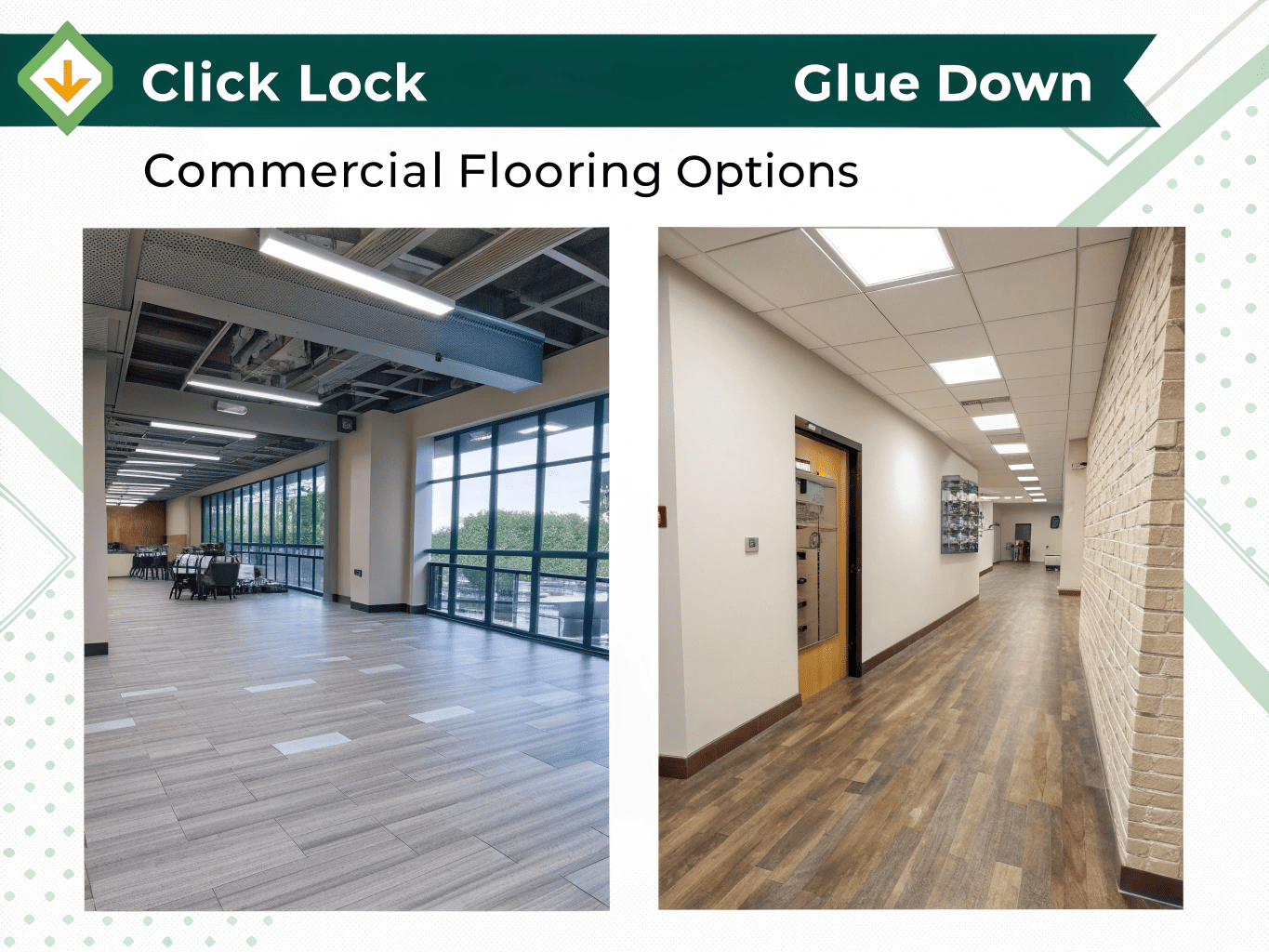

Choosing commercial flooring is tough; you want lasting value. The wrong decision can lead to high repair or replacement costs down the line. Let’s explore Click Lock and Glue-Down systems for true long-term benefits.

Click Lock often provides better long-term value with easier installation and repair. However, glue-down excels in stability for very high-traffic or heavy load areas. The best choice really depends on your specific commercial needs and priorities.

It’s a big decision, I know from my experience here at CloudsFlooring. Many of my clients, like Mark from the UK who buys LVT flooring for his distribution business, ask me about this all the time. He needs flooring that’s top quality, looks good for his rebranding efforts, and is competitively priced. To help you decide what’s best for your project, let’s dive deeper into each system.

What are the disadvantages of click-lock flooring?

Click-lock flooring seems so easy. But are there hidden issues? Overlooking potential downsides now can lead to future headaches and unexpected costs for your business. So, let’s explore the potential drawbacks of click-lock systems.

Disadvantages include potential vulnerability to moisture in seams, especially with certain core materials. It’s also less suitable for very uneven subfloors and can cause noise if not installed with proper underlayment. Some types might also be pricier upfront.

When I discuss click-lock LVT or SPC flooring with my wholesale clients, I always emphasize understanding these points. While the ease of installation is a big plus, it’s not always the perfect fit for every commercial scenario.

Moisture Concerns with Click Systems

One common concern is how click systems handle moisture. While the surface of our LVT and SPC planks is waterproof, the seams between planks can be a weak point. If water seeps through, especially in commercial areas like busy cafes or restrooms, it could potentially damage the subfloor or even the core of some flooring types over time. For areas with frequent spills, this is a key consideration. I always advise clients to be mindful of the specific environment.

Subfloor Leveling: A Must

Click-lock systems are generally installed as a "floating floor." This means they aren’t directly adhered to the subfloor. Because of this, they are less forgiving of imperfections in the subfloor. If the subfloor isn’t flat and level, planks can flex underfoot, leading to stress on the locking mechanisms, potential squeaking, or even joint damage over time. Proper subfloor preparation is absolutely essential to avoid these issues. My client, Lori, who is a COO in the US, learned this the hard way on a project before she started sourcing from us; a poorly prepped subfloor led to issues later.

Managing Noise and Acoustics

Another point to consider is acoustics. Without a quality underlayment, click-lock floors can sometimes sound hollow or produce a clicking noise when walked on. This can be a particular concern in office environments or multi-story buildings. Using a good underlayment not only improves comfort underfoot but also significantly reduces sound transmission. We offer various underlayment options to pair with our LVT and SPC click systems.

Here’s a quick table summarizing these points:

| Issue | Description | Possible Mitigation/Consideration |

|---|---|---|

| Seam Vulnerability | Water can seep through seams, potentially damaging the core or subfloor. | Use in drier commercial areas; choose high-density core products like SPC with tight locking systems. |

| Subfloor Imperfections | Less tolerant of uneven subfloors; can lead to flexing or joint damage. | Ensure thorough subfloor leveling and preparation before installation. |

| Acoustic Performance | Can sound hollow or create clicking noises without proper underlayment. | Always install with a high-quality acoustic underlayment; select thicker, more rigid planks. |

| Heavy Static Loads | May indent under very heavy, static loads if the core isn’t rigid enough. | For areas with heavy fixed furniture or equipment, ensure the chosen product’s density is suitable. |

What are the disadvantages of glue down vinyl plank flooring?

Glue-down flooring is known for its robustness. But what could go wrong? Installation complexity and potential removal difficulties are often overlooked aspects. Let’s uncover the downsides of glue-down vinyl for a balanced view.

Disadvantages of glue-down vinyl include a more complex and often time-consuming installation process. There’s also the potential for VOCs from adhesives during installation, and removal can be very difficult and costly later on.

Glue-down LVT, like our dry back ranges, offers incredible stability, which is why some clients prefer it for very specific applications. However, it’s important to weigh these potential drawbacks.

Installation: A More Involved Process

Unlike click systems, glue-down installation is definitely not a typical DIY job for large commercial spaces. It requires careful application of adhesive to a meticulously prepared subfloor. The subfloor must be perfectly smooth, clean, and dry. Any contaminants or imperfections can compromise the bond. This process is more labor-intensive, takes longer, and usually means higher installation costs. [Personal Story Placeholder: Maybe a time a client underestimated installation complexity].

Adhesive Considerations: VOCs and Longevity

The adhesives used are a big factor. Some traditional adhesives can release Volatile Organic Compounds (VOCs) during and after installation, which can be a concern for indoor air quality, especially in environments like healthcare or schools. I always recommend opting for low-VOC or zero-VOC adhesives. Also, the long-term performance of the adhesive is crucial. If the wrong adhesive is used or applied incorrectly, you might face issues like planks coming loose over time, which is a headache no business owner wants.

The Challenge of Removal

This is perhaps the biggest drawback. Removing glue-down flooring is a tough, messy, and labor-intensive job. The planks often have to be scraped up, and then the old adhesive needs to be removed from the subfloor, which can sometimes damage it. If you’re leasing a commercial space or anticipate changing the flooring within a few years, glue-down might not be the most practical choice due to these removal challenges. This is a common concern for clients who need flexibility.

Here’s a summary of potential glue-down issues:

| Issue | Description | Possible Mitigation/Consideration |

|---|---|---|

| Installation Complexity | Requires skilled labor, meticulous subfloor prep, more time, and careful adhesive work. | Factor in professional installation costs and extended project timelines; ensure experienced installers. |

| Adhesive VOCs | Some adhesives release Volatile Organic Compounds, impacting indoor air quality. | Specify and use low-VOC or zero-VOC adhesives; ensure adequate ventilation during installation. |

| Difficult Removal | Very hard to remove planks; can damage the subfloor and is highly labor-intensive. | Consider the long-term plan for the space; less ideal for temporary installations or leased premises. |

| Subfloor Sensitivity | Requires an extremely smooth and clean subfloor for proper, lasting adhesion. | Budget for potentially extensive subfloor preparation, including grinding or leveling compounds. |

Is it better to click or glue down flooring?

You need the best flooring for your commercial project. So, click or glue? Choosing incorrectly can significantly impact your project’s budget, timeline, and long-term satisfaction. Let’s weigh the pros and cons to help you decide.

Neither system is universally "better." Click flooring often wins for its easier, faster installation and simpler plank replacement. Glue-down provides superior stability, especially for heavy commercial use and areas prone to high moisture. The best choice depends on your specific needs.

I often tell my clients, like Mark and Lori, that understanding the unique demands of their specific commercial space is the first step. A high-traffic retail store might have different needs than a corporate office.

Installation Speed and Cost Dynamics

For installation, click-lock systems are generally much faster and can sometimes be installed by a competent in-house maintenance team, potentially lowering labor costs. There’s no glue, no waiting for adhesive to cure, so the floor can be used almost immediately. This is a big plus for businesses wanting to minimize downtime. Glue-down, on the other hand, requires more skilled labor for adhesive application and a more intensive subfloor preparation, adding to both time and cost.

Durability Showdown: Specific Use Cases

In terms of overall durability, both can be excellent. Our LVT and SPC flooring, whether click or glue-down, is designed for commercial wear and tear. However, for areas with extremely heavy rolling loads (like hospital gurneys or pallet jacks in a stockroom) or places with constant, heavy foot traffic and potential for significant spills, glue-down often has the edge because it’s fully bonded to the subfloor. This creates a very stable, immovable surface. For most other commercial applications, like offices or boutiques, a quality click system, especially SPC with its rigid core, performs exceptionally well.

Weighing Overall Project Costs

When looking at costs, you need to consider more than just the material price. Click flooring material might sometimes be slightly higher per square foot, but the savings on installation labor and time can offset this, making the total project cost lower. Conversely, glue-down material might seem cheaper initially, but professional installation, adhesive costs, and longer project duration can increase the overall expense.

Here’s a comparative table:

| Feature | Click Lock Flooring (e.g., SPC/LVT) | Glue-Down Flooring (e.g., LVT Dry Back) |

|---|---|---|

| Installation Speed | Faster, less downtime. | Slower, requires adhesive curing time. |

| Installation Skill | Moderate, potentially DIY for smaller areas. | High, professional installation recommended. |

| Subfloor Prep | Needs level subfloor, can use underlayment. | Needs very smooth, clean, non-porous subfloor. |

| Stability | Good, but can flex under very extreme loads. | Excellent, very stable, ideal for heavy loads. |

| Moisture (Overall) | Surface waterproof; seams need care. SPC is great. | Generally better if adhesive is waterproof & fully sealed. |

| Repair | Easier to replace individual planks. | More difficult and disruptive to replace planks. |

| Removal | Relatively easy to remove and replace. | Difficult, messy, and potentially costly to remove. |

| Upfront Cost | Material can be slightly higher; lower labor cost. | Material can be lower; higher labor & adhesive cost. |

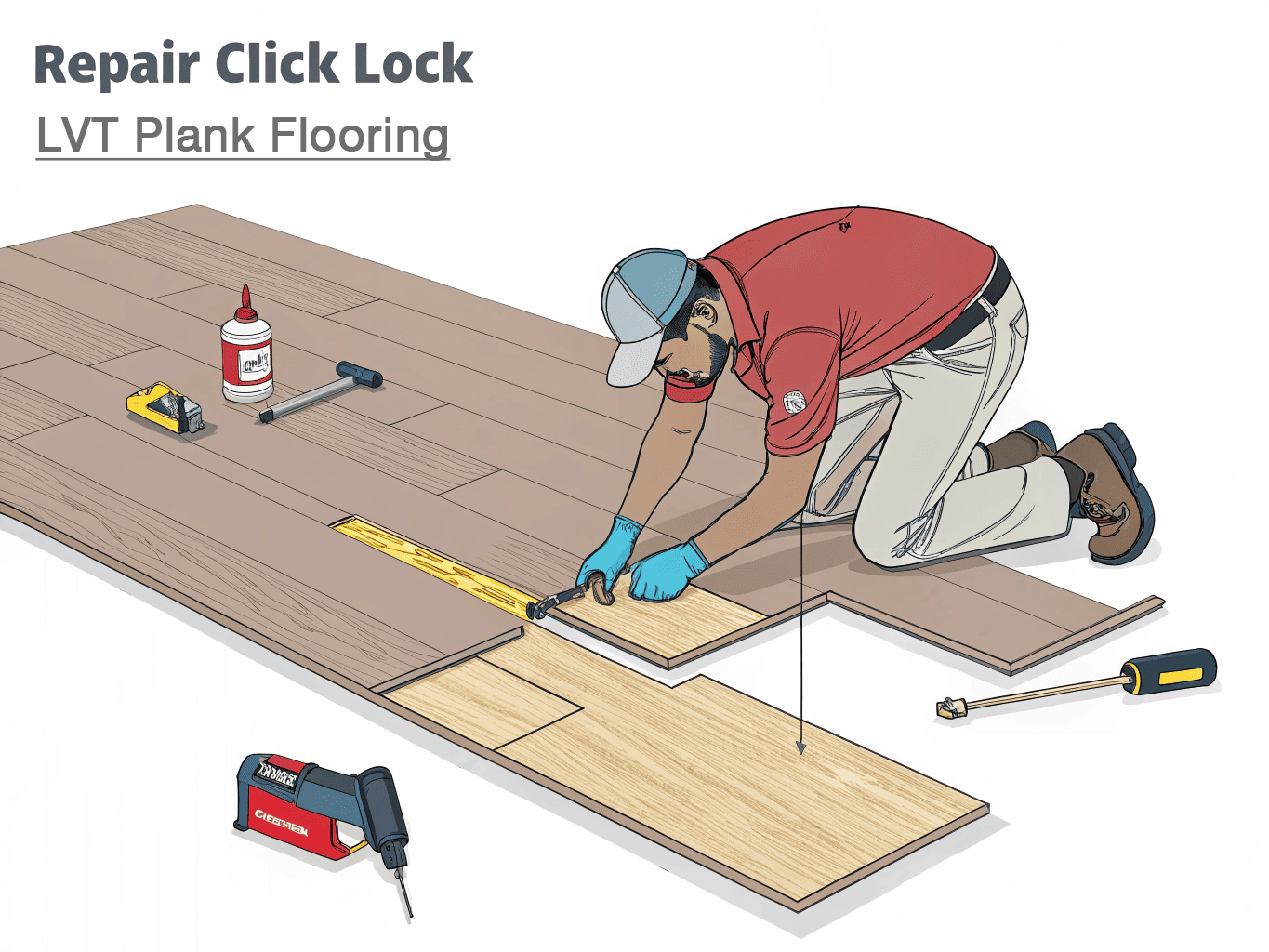

How does the repairability (replacing damaged sections) compare between Click Lock and glue-down commercial floors?

Damage happens, even to the toughest floors. Easy repairs save money and time. Complex repairs mean more disruption, more downtime, and higher costs for any business. So, let’s see which system is easier to fix when accidents occur.

Click Lock flooring is generally much easier and cheaper to repair. Damaged planks can often be individually unclicked and replaced without disturbing the rest of the floor. Glue-down repairs are more complex, time-consuming, and typically require specialized tools and skills.

This is a big factor for my clients. Lori, the COO from the US who sources SPC flooring from us, always emphasizes the need for easy maintenance. Minimizing disruption is key for her company’s operations.

Click Lock: The Simpler Fix

If a plank in a click-lock floor gets damaged – say a deep scratch or a chip – the repair process is relatively straightforward. You typically need to carefully unclick the planks in the row leading to the damaged one, replace the affected plank with a new one, and then re-click everything back into place. With some skill, you might even be able to replace a plank in the middle of the floor without disassembling the entire row, depending on the specific locking system. This usually means minimal downtime and can often be handled by a general maintenance person if they’re careful. Always keep some spare planks from the original batch for perfect matching!

Glue-Down: A More Involved Repair

Repairing a damaged glue-down plank is a different story. The damaged plank must be cut out very carefully to avoid damaging surrounding planks. Then, the old adhesive needs to be thoroughly scraped from the subfloor. A new plank is then cut to fit, new adhesive is applied, and the plank is set in place, often with weight on it while the adhesive cures. This process requires more skill, specialized tools (like a heat gun to soften adhesive or specific cutting tools), and is more time-consuming. There’s also a higher risk of slight variations if the replacement plank isn’t from the exact same batch, though this is true for any flooring.

Cost and Time Implications of Repairs

Naturally, the simpler process for click-lock repairs translates to lower costs and less time. You’re primarily looking at the cost of the replacement plank and minimal labor. For glue-down, the labor involved is much more significant, potentially involving a professional flooring installer, and the time the area is out of commission can be longer due to adhesive curing. This is a key consideration for the long-term value equation.

Here’s a comparison:

| Aspect | Click Lock Flooring | Glue-Down Flooring |

|---|---|---|

| Process | Unlock surrounding planks, replace damaged one, relock. | Cut out damaged plank, scrape old adhesive, carefully glue in new plank. |

| Skill Level | Often manageable by skilled maintenance staff or DIY. | Usually requires a flooring professional for a clean repair. |

| Time Taken | Relatively quick, minimal disruption to business. | Can be time-consuming, potential for more mess and longer curing. |

| Cost | Lower, primarily cost of replacement plank and simple labor. | Higher, includes more intensive labor, potentially new adhesive, and more time. |

| Matching | Excellent if you have spare planks from the same batch. | Good with spares, but surrounding floor wear might make it more noticeable. |

Is Click Lock generally faster to install, potentially reducing labor costs and downtime for businesses?

Time is definitely money in the commercial world. Faster installation means a quicker project completion. Long installations can mean extended business downtime and potential lost revenue. So, let’s verify if Click Lock truly speeds things up for businesses.

Yes, Click Lock flooring is significantly faster to install than glue-down systems. This speed directly translates into reduced labor costs and minimizes business downtime, offering a clear advantage for many commercial projects looking for efficiency.

Many of my B2B clients, who are distributors themselves, appreciate this aspect. When they supply our LVT or SPC click flooring to their commercial customers, the reduced installation time1 is a major selling point. For instance, Mark in the UK often highlights this to his clients who need rapid refurbishment of retail or office spaces.

The Speed Advantage of Floating Floors

The "floating floor" nature of click-lock systems is the key to their installation speed. Planks simply click together over an underlayment – there’s no messy adhesive to spread and no waiting time for glue to dry or cure. Once the last plank is laid, the floor is ready for foot traffic and furniture. This is a massive benefit for projects with tight deadlines, like retail stores needing to open quickly or offices wanting to minimize disruption to employees.

Labor Cost Reduction

Fewer installation steps and less time on site naturally mean lower labor costs. While subfloor preparation is still important for click systems, the actual laying of the floor is much quicker. For large commercial areas, this can result in substantial savings on the overall project budget. As a factory owner, I see how these efficiencies at the installation stage add to the overall value proposition of our click LVT and SPC products.

Minimizing Business Disruption

For an existing business undergoing renovation, minimizing downtime is critical. A lengthy flooring installation can mean closing sections of the business or even the entire operation. Click-lock’s speed allows businesses to get back to normal operations much faster. I’ve had clients tell me this was the deciding factor, especially in hospitality or retail where every day of closure impacts revenue. [Personal Story Placeholder: An anecdote about a client choosing click-lock specifically for speed].

Let’s look at the key factors influencing this:

| Factor | Click Lock Flooring | Glue-Down Flooring |

|---|---|---|

| Installation Steps | Minimal subfloor adjustments (if needed), roll out underlayment, click planks together. | Extensive subfloor prep, trowel adhesive, lay planks, roll floor, wait for cure. |

| Adhesive Curing Time | None. Floor can be used immediately after installation. | Requires specific drying/curing time (hours to days) before heavy use. |

| Labor Hours | Significantly fewer man-hours required per square meter. | Significantly more man-hours due to meticulous adhesive work and prep. |

| Skill Level for Speed | A competent team can install large areas quickly. | Even skilled teams are limited by adhesive working times and curing. |

| Impact on Business Downtime | Minimal. Often possible to install in sections or overnight. | Can be substantial depending on area size, adhesive type, and curing needs. |

Does the enhanced stability of glue-down offer advantages under very heavy rolling loads often found in commercial settings?

Heavy rolling loads can really stress a floor. Stability is absolutely key in these situations. Unstable floors can quickly deteriorate, leading to costly repairs or premature replacement. So, let’s see if glue-down’s renowned stability is truly superior here.

Yes, the enhanced stability of glue-down flooring offers significant advantages under very heavy rolling loads1. Because it’s fully bonded, it prevents movement, gapping, and premature wear, making it the ideal choice for demanding commercial environments.

This is a critical point for some of my clients who supply flooring for specialized commercial projects, like hospitals or industrial-lite spaces. While our SPC click flooring is incredibly rigid and performs well under general commercial traffic, extreme loads require a different approach.

The Science of Glue-Down Stability

With glue-down installation, each plank is firmly adhered to the subfloor, creating a single, unified surface. This direct bond means there’s no vertical movement or lateral shifting of planks, even under the pressure of heavy items being rolled across them. This is why it’s the preferred method in environments where you might have hospital beds, heavy diagnostic equipment on wheels, loaded pallet jacks in retail backrooms, or constant cart traffic in supermarkets. The floor effectively becomes an integral part of the subfloor structure.

Ideal Applications for Glued-Down Floors

Think about commercial kitchens with heavy mobile cooking stations, laboratories with wheeled equipment, or busy airport terminals with constant luggage cart traffic. In these scenarios, any micro-movement in the flooring, which can sometimes occur with floating floors under extreme stress, could lead to joint damage or disengagement over time. Glue-down LVT, especially our robust dry back products, eliminates this risk, ensuring longevity even in the toughest conditions.

Click Lock Limitations with Heavy Loads

While high-quality click-lock flooring, especially rigid core SPC, is very durable and suitable for most commercial applications (offices, boutiques, classrooms), it has limitations when it comes to extremely heavy and frequent rolling loads or significant point loads. The locking mechanisms, though strong, are not designed to withstand the same kind_of concentrated, dynamic stresses as a fully adhered floor. Over time, this could lead to wear on the joints or a feeling of slight movement. For these niche, heavy-duty applications, I always guide my clients towards a glue-down solution.

Let’s summarize the stability aspect for heavy loads:

| Feature | Click Lock Flooring (even rigid core SPC) | Glue-Down Flooring (LVT Dry Back) |

|---|---|---|

| Bond to Subfloor | Floating system; planks interlock but are not fixed to the subfloor. | Directly and fully bonded to the subfloor with adhesive. |

| Movement under Heavy Load | Can experience micro-movement or flexing, potentially stressing joints over time. | Minimal to no movement; floor acts as a single, monolithic, stable unit. |

| Suitability for Heavy Loads | Good for moderate to heavy commercial traffic; less ideal for constant, extreme loads. | Excellent; specifically designed to withstand heavy point loads and frequent rolling traffic. |

| Risk of Joint Damage | Higher risk if subjected to loads beyond its design, or if subfloor isn’t perfect. | Very low risk as there are no "floating" joints to stress. |

| Typical Use Cases | Offices, retail, hospitality, education. | Hospitals, supermarkets, labs, industrial back-of-house, areas with pallet jacks. |

Conclusion

Choosing between click-lock and glue-down depends on your project. Consider installation ease, durability needs, repair simplicity, and load demands. This helps you make the best long-term value decision for your commercial space.

The above data is for reference only.